Automated Selective Plating Takes Off With Safran Project

Sifco ASC has partnered with Safran on various surface finishing projects for more than 20 years, including recent work to increase wear resistance on an aircraft’s axles.

Safran Landing Systems, a leading manufacturer of landing gear systems, is focused on providing solutions that are not only reliable and robust, but increasingly weight efficient and environmentally responsible, providing overall value across an aircraft program.

Safran’s facility in Gloucester has been at the forefront of landing gear technology for more than 80 years. Today, the 100,000-m2 site employs around 1,200 people, and its core competencies include design, research, development, testing and systems integration, together with a comprehensive, state-of-the-art production capability. It is here that the company manufactures the landing gear for a number of the world’s leading commercial aircraft.

Demanding aerospace operating conditions present continual surface finishing challenges for manufacturers. Components need to be able to withstand friction, extreme temperatures and corrosive environments while continuing to operate at optimum levels. For Safran Landing Systems, one particular challenge came in the form of a landing gear bogie beam design.

Landing gear design includes a stop-pad between the bogie beam and vertical part of the component to prevent wear as it is retracted into the fuselage. However, this impact results in potential wear at the interface, with a further risk of atmospheric corrosion. A design modification was agreed upon involving the application of a nickel chrome electrolytic protective treatment.

Sifco Applied Surface Concepts has partnered with Safran on various surface finishing projects for more than 20 years, including recent work to increase wear resistance on an aircraft’s axles. These projects are carried out using the Sifco Process, a method of electroplating localized areas on components without the use of an immersion electroplating tank.

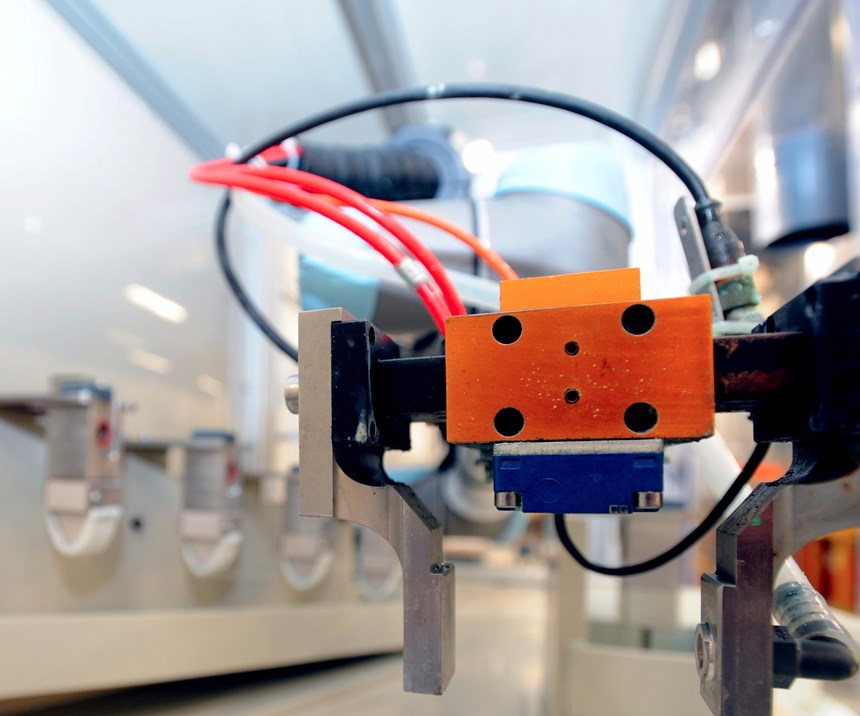

Neil Kenyon, process group manager, initially approached Sifco ASC to investigate the potential of the Sifco Process as a solution for the nickel plating application. While it was advised that this could be solved by manually plating a layer of nickel underneath a layer of chrome on the section of the bogie beam affected by corrosion, Safran’s manufacturing quality standards required the process to be highly traceable and repeatable. Sifco ASC’s UK team consulted its French specialist engineering R&D department. Following a full situation analysis, the team recommended that the Sifco Process should be automated using a collaborative robot in order to adhere to Safran’s manufacturing standards. However, this had never been done before and would require significant engineering expertise. In order to achieve the results demanded by the aerospace specifications, the two teams embarked on a collaborative research project.

Initial work began at the end of 2013. Safran tested the nickel material in its specialist facility under simulated take-off and landing conditions. Once it was confirmed that the material was suitable in early 2014, Sifco began work on designing the robotic system. During this time, to fast-track the benefits of the Sifco Process, the plating was carried out manually.

The robot, now fully operational at Safran’s facility, provides the company with a precise and highly traceable, repeatable and accurate process, well-suited to the high-tech facility in which it sits. The integrated computer logs all relevant information, including parameters plated, batch numbers for the solution, current densities and solution levels. The fully automated system also adheres to the company’s health and safety policy, as it minimizes human contact with harmful chemicals. Safran currently processes 30 bogie beams per month, and the team is looking to expand its use into other areas of the company.

The Sifco Process has since been specified into the manufacturing process of new landing gear to prolong the corrosion protection. It is also being rolled out into Safran’s Mexico facility, where landing gear components are also manufactured.

For information, visit sifcoasc.com

Related Content

Bryan Leiker, MFACA, Discusses CARB Public Hearing Over Calif. Hex Chrome Ban

Bryan Leiker, executive director, Metal Finishing Association of California, offers a recap of a January 27, 2023, public hearing conducted by the California Air Resources Board prior to an impending ruling on a proposed ban of hexavalent chromium use for finishing operations in the state.

Read MoreNADCAP Shop Digitizes to Eliminate Paper Trail

Customizable ERP software has transformed a 27-year-old manual metal finishing job shop into a state-of-the-art paperless company with full digital traceability in about 10 months.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read More10 Anodizing Best Practices

Following this list of guidelines can help to increase the performance, cost effectiveness and quality for your anodizing operation.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)