Basics of Power Brush Selection

Tips on how to choose the right brush for the right application...

The unavoidable and unintentional by-product of manufacturing practices is the generation of burrs and sharp edges. Besides the obvious safety hazards associated with burrs and sharp edges, the presence of these features adversely affects the functionality and performance of the manufactured component. Manufacturers have resorted to a number of methods to remove these unwanted attributes.

Deburring practices can be classified into two larger groups: mechanical and chemical deburring. Some of the most common methods to mechanically deburr parts include: sanding, tumbling, sandblasting,and brushing.

All of the above-mentioned deburring methods have advantages as well as disadvantages. One of the biggest disadvantages is the cost associated with the purchase of specific equipment. Perhaps the most economical solution to mass deburr manufactured parts using current equipment is the use of power brushes.

The industrial applications of brushes vary from paint removal and deburring to honing and polishing. These surface-conditioning tools can be used on a variety of materials, including aluminum, steel, carbide, wood, glass and practically any material imaginable. The advantages of brushes include flexibility, durability and repeatable uniform results. The physical designs as well as some of the available adapters make these tools readily adaptable to machinery that is widely used in toady’s manufacturing environment (Left).

Although many brush types and configurations are available (See next four photos), the two major components that make up a brush are the filament type and the mounting hardware.

The purpose of the mounting hardware is to act as the means of introducing the filament to the work piece. The more important component, which is responsible for performing the actual deburring, is the filament. Filament types range from artificial to natural filaments. Some of the naturally occurring filaments used in brushes are Tampico, sisal, horsehair and a wide range of natural filaments. The use of these filaments varies according to the application. Generally, these filaments are not abrasive by themselves but are used for polishing and cleaning applications in conjunction with some sort of abrasive compound. The commonly used filament types are the abrasive and crimped wire filaments. Examples of crimped wire filaments vary from steel, stainless steel, bronze, brass, and phosphorous bronze and in rare cases gold.

The selection of abrasive filaments varies from silicon carbide to aluminum oxide to polycrystalline diamond. Depending on the grit size, these filaments can be used for deburring, polishing, blending, and many other surface conditioning applications. The filament is a mixture of specially formulated nylon, with varying grit sizes of abrasive crystals homogeneously distributed (See Fig 1).

In many cases, the filament has additives that aid with heat transfer and moisture absorption. Because the carrier is nylon, heat is a significant limiting factor during application. The use of coolant with a pH level between 2 and 9 is strongly recommended. If the use of liquid coolant is not an option, the use of forced air is recommended to keep the brush cool. The melting point of most nylon filament is 410F. At 210F, the abrasive filament looses 70% if its stiffness. Due to the loss of beam strength (stiffness), the brush will not perform as aggressively and predictably as it had at the start of the application. To counter the loss of stiffness, the uses of side plates or bridles are suggested.

The crystal structure, in conjunction with grit size, determines the aggressiveness of the filament. The silicon carbide and polycrystalline diamond crystals are characterized by sharp, jagged edges where the aluminum oxide and aluminum silicate have a more rounded crystalline structure (See Fig 2).

Due to these characteristics, a brush with silicon carbide filament is more aggressive than a brush with aluminum oxide impregnated filament. The most commonly used abrasive grain sizes vary from 46-grit (coarse) up to 1,000-grit (fine). For an aggressive deburring application, the use of coarse abrasive grain size is recommended, where as the 1,000-grit grain size can be used for polishing applications. Another consideration to keep in mind while selecting a brush is the type of industry the part is being used in. Since silicon carbide filament is more jagged, it tends to break off and embed into the work piece. Because of this characteristic, a number of fabricators in the aircraft industry insist on using a brush with aluminum oxide filament rather than silicon carbide impregnated filament.

Wire Filament

The most important trait of crimped wire filament is the hardness of the wire. Generally, the carbon steel wire has a hardness of Rc 55-60. The stainless steel wire on the other hand is between Rc 30-35. Brass, bronze and beryllium copper filaments are used where softer materials need work (rubber, aluminum), as well as in low-sparking applications. The important characteristic of wire filament is that the deburring takes place only at the tip of the wire. Since the wire tip is the area where a sharp edge can be found, this is the only part of the wire that is capable of cutting.

The majority of brushes sold are made using crimped wire, which has multiple benefits. Perhaps the most important feature is its ability to break off and expose new cutting points. If the crimped wire is compared to a wave, the breaks are generally occurring at the crest and trough of the wave. These points act as stress risers; therefore the initial break takes place at these points and exposes new sharp cutting points.

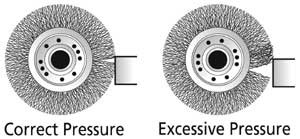

A common application problem encountered is over the penetration on wire brushes. If a wire brush is over penetrated, the filaments act more like small hammers impacting the work piece surface. The easiest way to determine if a wire brush is over penetrated is to examine a part after the initial deburring application. If the edge of the part resembles a shot peened surface, with the sharp edge still remaining, most likely this can be corrected by decreasing the brush penetration. The recommended brush penetration can be seen in Figure 3.

Brush Selection

When selecting a brush for an application, a number of questions need to be addressed. The two most important questions are what is being pursued (i.e. deburring, edge break, polishing, cleaning act.), and what is the material that needs attention. For example, if the goal is to deburr a stainless steel tube that was saw cut, the use of either an abrasive or stainless steel wire brush is recommended. The use of a stainless steel brush is recommended to reduce contamination on the work piece. Where a carbon wire brush will probably deburr the part faster, it will also leave traces of carbon steel that cause the part to oxidize. If the tube is harder than 35 Rc, the only remaining option is the use of abrasive filament. Depending on the equipment used and the limitations of the equipment, either a cup or a radial brush will perform the job. Usually the largest brush that the equipment can handle is recommended. The benefits of this are two-fold. Due to the size of the brush, the part can probably be deburred in one pass as opposed to two or more passes. The other advantage of using a larger brush is that the brush will have to be changed less frequently, therefore less downtime for the machine.

As with any power tool, safety is a paramount concern when it comes to deburring applications. Just as cutting tools dull and deteriorate over time, so do brushes. After a number of cycles, the wires fatigue, break and fall out of the brush. At the various operating speeds, these loose wire filaments have enough velocity to puncture through clothing and skin. For offhand deburring, the use of leather gloves and a thick leather apron is recommended along with full-face shield and work boots.

Related Content

How to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreHow to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)