Calculating Electroless Nickel Square Footage

Matthew Wojcik of Coventya Inc. offers advice for calculating the proper square footage of work that can be processed through an EN bath.

Matthew Wojcik is a senior R&D chemist at Coventya Inc. Visit coventya.com

Q: We are a plating shop looking to expand our capabilities in electroless nickel. I understand that EN baths have a finite life so if we install a 200 gallon tank, how much work (sq. ft.) would be we able to process out of one bath? We typically plate to a thickness of 0.0005 inches of a high phosphorous system for our customers.

A: Before we get into the calculations, here is some background information that is required:

- Traditional high phosphorous (i.e. > 10.5% w/w P) systems operate at 6 g/L (or 0.8 oz/gal) of Ni metal in the working solution. This is the amount of nickel to be depleted per 1 MTO cycle.

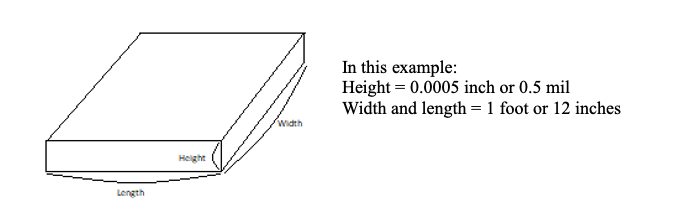

- Below is the visual representation of what we are looking to calculate:

As we are trying to calculate for the square footage, or the area, that can be processed through a solution, you would also need to consider the thickness of your final product. As the thickness increases per part, the total amount of nickel eligible to be plated decreases, thus decreasing the amount of area that can be plated.

-

Deposit

% PhosphorousDeposit

% NickelDeposit Density (g/cm3)

0

100

8.9

1

99

8.8

2

98

8.7

3

97

8.6

4

96

8.5

5

95

8.4

6

94

8.3

7

93

8.2

8

92

8.1

9

91

8.0

10

90

7.9

11

89

7.8

12

88

7.7

13

87

7.6

*Mallory, G.; Hajdu, J. Electroless Plating: Fundamentals and Application; Noyes Publications: New York, NY, 1990.

-

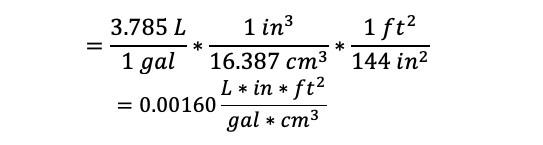

Calculation of the conversion factor to achieve ft2/gal/MTO:

a. In order to convert the units from the information that you generated for your deposit, a conversion factor needs to be generated to ensure the units align. This factor is generated below:

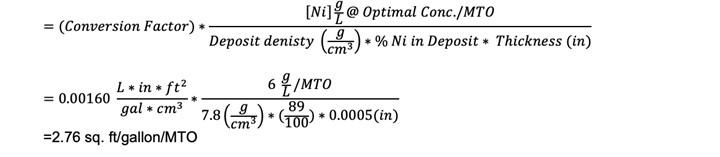

Calculation of high phosphorous example (ft2/gallon/MTO) from the information provided:

Therefore, for a 200-gallon tank, you would be able to process 553.2 ft2/MTO.

The end result will be a good estimate of the amount of work that can be processed under ideal conditions in the bath per MTO. The maximum MTO that you will be able to achieve with the bath will depend on the properties of the end customer requests, as well as, the type(s) of substrate being processed. As the bath continues to age, the accumulation of by-products (e.g. Na, SO4 and orthophosphate) and contaminants will begin to impact the deposition process and therefore the coating integrity.

Additional conditions may also affect the square footage of work that can be processed in an EN bath. These include, but are not limited to:

- Operating the bath outside recommended operating conditions. Doing so may have an effect on the amount of nickel deposited, resulting in a less efficient bath.

- Plate-out in the tank. As you plate nickel on racks, barrels, the tank, etc., you are consuming nickel in your tank, thus depleting the amount that can be utilized for the intended plating operation.

- Over-plating the parts. If the desired thickness is not consistently being reached, you may observe a decrease in the amount of work that can be processed through your tank, as there will be excess depletion per MTO not being accounted for in the calculations.

In conclusion, calculating the proper square footage of work that you would be able to process through your EN bath is key for determining the proper costing for a job, as well as, providing a reference for proper bath performance. If you begin to notice large deviations from the expected optimal yield, it could be an indication of possible loss of efficiency due to idling of the plating tank for long periods of time without work or unaccounted for nickel plate-out. These can be areas of possible process improvement to reduce operating costs. Your electroless nickel supplier should be able to supply you with a handy calculator to generate these values for you in a simple and fast way.

Related Content

How to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreSuccessful South African Plater Beating the Odds

Remaining focused on quality and reliability, Team Plating Works stays profitable in a volatile and challenging economy.

Read MoreLiquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

Read MoreInnovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

Read MoreRead Next

40 Under 40: Class of 2021

Each year, PF editors comb through a long list of nominees with a wide range of skill sets to select the 40 Under 40 class. This year's finalists include engineers, operations managers, chemists, general managers, sales professionals and entrepreneurs working in the finishing industry.

Read MoreAvoiding Roughness and Pitting in Decorative Bright Nickel

Doug Lay of Coventya Inc. offers a troubleshooting guide for avoiding roughness and pitting in decorative bright nickel processing.

Read MoreTroubleshooting Bright Nickel Processes: How to Identify the Problem

For bright nickel process troubleshooting, Doug Lay of Coventya suggests narrowing the scope with a checklist.

Read More

.jpg;maxWidth=300;quality=90)