Celebrities Who Once Worked in Electroplating

Over many years, AESF/NASF stalwart Jack Dini contributed a series of fascinating columns to Plating & Surface Finishing, under the title Fact or Fiction?. What follows is a welcome addition to his output for the NASF. Still the prolific writer, Jack discusses celebrities (both scientists and non-scientists) who once worked in electroplating.

by

Jack Dini

Livermore, California, USA

Editor's Note: Over many years, AESF/NASF stalwart Jack Dini contributed a series of fascinating columns to Plating & Surface Finishing, under the title Fact or Fiction?. What follows is a welcome addition to his output for the NASF. A printable version of this article can be accessed HERE.

What do Thomas Edison, Richard Feynman, Charles Kettering and Louis L'Amour have in common? The answer is that for these celebrities, some time in their careers they were involved with electroplating.

Let's start with the most prolific one first.

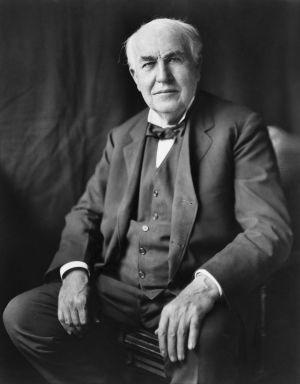

Thomas Edison

Library of Congress

Thomas Edison was an American inventor and businessman who has been described as America's greatest inventor. He developed many devices in fields such as electric power generation, mass communication, sound recording and motion pictures. These inventions, which include the phonograph, the motion picture camera and the long-lasting practical electric light bulb, have had a widespread impact on the modern industrialized world. He was one of the first inventors to apply the principles of organized science and teamwork to the process of invention, working with many researchers and employees. He established the first industrial research laboratory. His final count on U.S. patents was 1084 utility patents (patents for inventions) and 9 artistic design patents.1

On a single day, when he was forty and full of innovative fire, he had jotted down a hundred and twelve ideas for “new things,” among them a mechanical cotton picker, a snow compressor, an electrical piano, artificial silk, a platinum wire ice slicer, a system of penetrative photography (presaging radiology by twelve years) and a product unlikely to occur to anyone else except perhaps Lewis Carroll: “ink for the blind.”2

On February 6, 1912 he was granted a patent regarding a means of stuffing his electrode salt with miniscule, highly conductive “scales” of cobalt, alloyed with nickel to reduce oxidization to almost zero (TE Patent, Electroplating Apparatus, 1,016,875). Exquisite care was required to manufacture them. First, he electrodeposited what he called “a mere blush” of zinc on a copper plate. The plate was then washed and transferred to an electrolytic bath, in which a film of cobalt and nickel (proportionately mixed by separate anodes) was laid upon it to a depth of only 0.0002 of an inch. A third immersion, this time in a dilute acid, dissolved the zinc and caused tiny bubbles of hydrogen to rise off the copper and lift the alloy film. As it floated free, Edison wrote, it broke up into “small flakes or scales, which naturally assume a curved or curled shape - a phenomenon especially characteristic of cobalt. They were sized through microscreens before being annealed to a red heat in a hydrogen atmosphere, which treatment effects a very perfect cleaning of the surfaces.”

Nine years of intellectual, mechanical and chemical labor led up to his announcement on June 26, 1907 that “the storage battery is an accomplished fact.” When the first 1.2 volt A-cells appeared in July - slender, light and lustrous, so intricately engineered that they approached solid state - did awareness spread that Edison had pulled off a revolution in electrochemistry.

He had done it by returning to flake technology, using nickel leaf this time, plating it so thin that it floated on the air like gossamer. Two hundred and fifty sheets would have to be plated flat to match the thickness of a visiting card. They were drawn off rotating drums that he dunked, alternately and rapidly, into baths of copper and nickel electrolyte. Each deposition was washed and dried, the accumulated layers building up hardly more substantially than crossed shadows. When they laminated out at 0.3969 of a millimeter, the sheet was stripped and cut into tiny squares, which were then soaked in a solution that ate away the copper. This left 120 nickel flakes, each about 1/25,000 inch thick.2

In “Process of Electroplating,” U.S. Patent 964,096, July 12, 1910, he talks about hydrogen gas clinging to the cathode and making the surface “more or less warty and rough.” In this patent, he claims an improved plating process where he “very largely eliminates the formation of hydrogen bubbles on the deposited surfaces.” He used chlorine to obtain improved results in plating solution and based on this information, Henry Brown3 tried the disinfectant chloramine T, the N-chloro derivative of p-toluene-sulfonamide. This led to the discovery of the use of sulfonamides and saccharin in nickel solutions.3,4

A subject that should be of unique pride to electroplaters, is Edison's very last patent: “Holder for Article to be Electroplated,” U.S. Patent 1,908,830, May 16, 1933. This was for a holder for plating a number of diamonds simultaneously, number 1084 of all his patents.

One last note - Edison, who seemed to have a habit of poisoning himself around the turn of every year, inhaled so much hydrogen cyanide on January 1, 1906 that he had to hurry outside and clear his lungs with cold air. A lab assistant said that “the old man persisted in handling such things as if they were milk...I suppose they will the death of him yet.”2

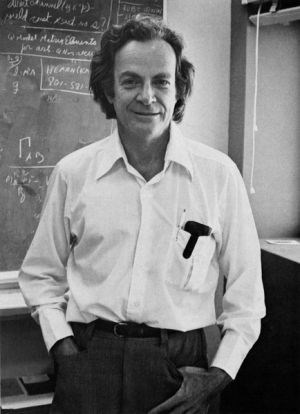

Richard Feynman

Wikipedia Fair Use

Richard Feynman (May 1918-February 1988) was an American theoretical physicist, known for his work in the path integral formulation of quantum physics, the theory of quantum electrodynamics, and the physics of the superfluidity of supercooled helium, as well as in particle physics. For contributions to the development of quantum electrodynamics, Feynman received the Nobel Prize in Physics in 1965.

He assisted in the development of the atomic bomb during World War II and became known to a wide public in the 1980s as a member of the Rogers Commission, the panel that investigated the Space Shuttle Challenger disaster. During a televised hearing, Feynman demonstrated that the material used in the shuttle's O-rings became less resilient in cold weather by compressing a sample of the material in a clamp and immersing it in ice-cold water. The commission ultimately determined that the disaster was caused by the primary O-ring not properly sealing in unusually cold weather at Cape Canaveral.5

As a teen, Feynman worked one summer for the Metaplast Corporation. The company was starting to plate plastics and they needed a chemist. Their biggest problem was getting the plated metal to actually adhere to the plastic. He spent the summer helping them improve their process. But the entire chemistry lab was just him. A college student on summer break.6

Here's the rest of the story from Feynman:

“A few years later, I was in Los Alamos, where there was a man named Frederic de Hoffman. One day we were eating he told me that he had been working in England before coming to Los Alamos.”

“What kind of work were you doing there?” I asked.

“I was working on a process for metal plating plastics. I was one of the guys in the laboratory.”

“How did it go?”

“It was going pretty well but we had our problems. Just as we were beginning to develop our process, there was a company in New York called Metaplast Corporation. They were developed further than we were. You could tell from ads in Modern Plastics that they were way ahead, so it was no use trying to compete with an American process.”

“How many chemists do you think the Metaplast Corporation had?”

“Oh! They must have had a real chemistry department. I would guess they must have had twenty-five or fifty chemists, and a chief research chemist with his own office. Guys coming in all the time with research projects they're doing, getting his advice and rushing off to do more research. How the hell could we compete with them?”

Then Feynman revealed:

“You'll be interest and amused to know that you are now talking to the chief research chemist for the Metaplast Corporation, whose staff consisted of one bottle washer!”6

A side note - the Metaplast Corporation went out of business after taking on a big job that they really couldn't handle. Here's a what if: If “chief chemist” Feynman decided to stay at Metaplast instead of heading off to graduate school, would he today be one of our more memorable plating heroes?

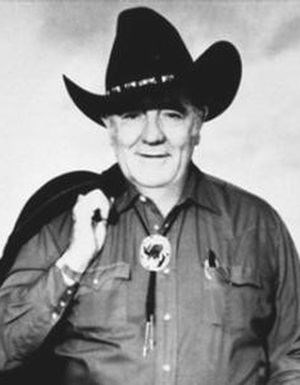

Charles F. Kettering

Public Domain

Charles F. Kettering (August 1876-November 1958) was an American inventor, engineer, businessman and the holder of 186 patents. He was a founder of Delco and was head of research at General Motors from 1920 to 1947. His patents covered a wide range of topics: the motorization of the cash register, the electric auto starter, a portable lighting generator, leaded gasoline, Freon refrigerant, automobile paint, an incubator for premature babies, a treatment for venereal disease and chromium plating.7

Louis L'Amour

Wikipedia Fair Use

Louis L'Amour (1908-1988) was an American author. His books consisted primarily of western novels; however, he also wrote historical fiction, science fiction, non-fiction as well as poetry and short stories. Many of his stories were made into movies. At the time of his death in 1988 almost all of his 105 existing works were still in print, and he was considered one of the world's most popular writers. For ambition and for attention to realistic detail, the self-taught L'Amour would be hard to equal among western historical novelists; for a century, no one approached his mid-1990s figure of 225,000,000 copies in print.

Fifteen year old Louis L'Amour (1908-1988) dropped out of school in Oklahoma in 1923 and embarked on a Jack London-like education in hard work, soaking up facts and skills in orchards, cattle ranches, mines, logging shows, dockyards, electroplating and even boxing rings across the American West. In World War II he taught winter survival to Army recruits and served in the European theater.8

Talking about his early school years he said: “I wished to skip general science and take chemistry. At the time I had helped build several crystal radio sets and did some electroplating.”9

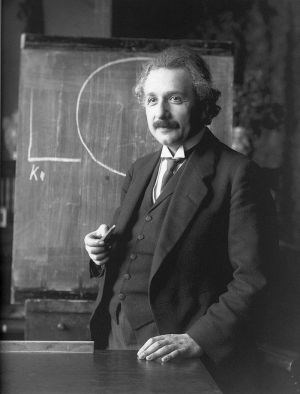

Albert Einstein

Public Domain

Albert Einstein (March 1879-April 1955) was a German born theoretical physicist who developed the theory of relativity, one of the two pillars of modern physics alongside quantum mechanics. He is best known to the general public for his mass-energy equivalence formula E = mc2, which has been dubbed “the world's most famous equation.”

Although Einstein didn't work in electroplating, his father and Uncle Jakob had operated a small electrochemical plant before it went bankrupt.10

Here's a final what if: Had his father's electrochemical facility been successful, would Einstein have remained in the business and provided us with another plating genius?

References

1. “Thomas Edison,” en.m.wikipedia.org, May 9, 2020.

2. Edmund Morris, Edison, Random House, New York, 2019.

3. H. Brown “Electrodeposition of Nickel from an Acid Bath,” U.S. Patent 2,191,813, (1940).

4. A.H. DuRose, “Some Contributions from U.S. Supply houses to Plating Science and Technology,” Plating, 57, 793, 1970.

5. “Richard Feynman,” en.m.wikipedia.org, May 6, 2020.

6. Richard P. Feynman, Surely You're Joking, Mr. Feynman, Bantam Books, New York, 1985.

7. David Halberstam, The Reckoning, Bantam Books, New York, 1986.

8. Thomas J. Lyon, The Literary West, Oxford University Press, 1999.

9. Louis L'Armour, Education of a Wandering Man, Bantam Books, New York, 1989.

10. Michael Guillen, Five Equations That Changed The World, Hyperion, New York, 1995.

About the author

.jpg;maxWidth=600)

Jack Dini earned a Bachelor of Metallurgical Engineering degree from Cleveland State University and began his career in the 1950s with Cleveland Supply Co. (now Pavco). He spent a few years at Republic Steel's research center and Battelle Columbus Laboratories. In 1962, he joined Sandia Laboratories, Livermore, CA, where he was involved with electrodeposition projects for 18 years before moving to Lawrence Livermore (LLNL) in 1980. He was section leader, fabrication processes. Responsibilities included direction of activities in four groups: electroplating and metal finishing, vacuum processes, metal fabrication, and plastics.

Mr. Dini is a prolific scientist. He is the author or coauthor of some 125 technical papers and, while many researchers are content to specialize in one or two fields, he made significant contributions to more than half a dozen disciplines in surface finishing. The scientific community is fortunate that he carefully documented his work, sharing it with others around the world. It includes plating uncommon metals, alloy plating, printed circuits, chemical milling, electrojoining and gathering electrochemical/property data.

Mr. Dini's byline also appears in several books. He has contributed to Modern Electroplating; Hydrogen in Metals; Properties of Electrodeposits: Their Measurement and Significance; Adhesion Measurement of Thin Films, Thick Films and Bulk Coatings (ASTM STP-640); Industrial Applications of Titanium and Zirconium (ASTM STP-830) and Electrodeposition: The Materials Science of Coatings and Substrates (1993).

Jack was a workhorse for the AESF. He was National President of the society, served a term on its Board of Directors, and was involved with organizing two annual conferences. As the 1985 Scientific Achievement Award recipient, he presented the 27th William Blum Lecture at SUR/FIN® '86 in Philadelphia, June 23. He contributed a series of columns, Fact or Fiction?, for many years in Plating & Surface Finishing.

In retirement, he continues as a prolific writer on an eclectic collection of subjects in a variety of publications, as well as a book, Challenging Environmental Mythology: Wrestling Zeus (2003).

Related Content

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

Read MoreNanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More