Chemical Switch Cuts Costs, Improves Safety

By replacing the sodium sulfide chemistry used in its nitrogen oxide (NOx) scrubber with a non-hazardous NOx control chemistry, ChemResearch Co. Inc. (CRC; Phoenix, AZ) reduced its operating costs and eliminated a health and safety hazard.

The BIONOxSOLVER™ chemistry, developed by Bionomic Industries Inc. (Mahwah, NJ), provides CRC with a safe, easy-to-handle, high-efficiency NOx scrubbing solution that eliminates the production of toxic and odoriferous hydrogen sulfide gas.

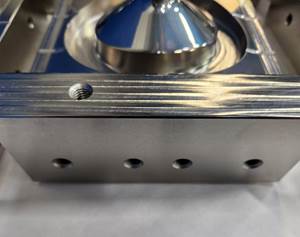

Since 1998, CRC had used sodium sulfide chemistry in the NOx scrubber at the end of its dedicated aluminum precleaning process. Used to prepare a cast aluminum cylinder for a small engine for hard chromium plating, the automated line cleans and etches the parts using various cleaner and acid baths. The acid baths contain nitric/water or straight nitric/hydrofluoric mixtures. Each load of parts has about 450 sq ft of surface area, with one load processed every seven to eight minutes, sometimes around the clock. When the parts come out of the acid baths, a large volume of NOx is released.

Captured by a ventilation system, the acid fumes are taken to a dedicated 10,000-cfm vertical packed-bed NOx scrubber. “A number of factors led us to begin looking for a less labor intensive and less hazardous alternative to the sodium sulfide chemistry,” explains CRC Director of Regulatory Affairs and Facility Development David Weed. “Making up that sodium sulfide tank was time-consuming and generated potentially hazardous vapors. Since the chemistry was potentially subject to annual regulatory reporting requirements, we were required to perform and maintain time-consuming record keeping.”

According to Weed, sodium sulfide use, coupled with sodium hydroxide, generates scale buildup on the scrubber tank and packing, making cleaning and maintaining the system labor-intensive. The scrubber also required an annual cleaning, which took approximately 28 man-hours, as well as the purchase and disposal of five drums of hydrochloric acid.

CRC was also concerned about the safety of the tank itself. It was inside another lined tank, vented with an exhaust duct into the scrubber to prevent release of fumes into the atmosphere and in a secure fenced area surrounded by a containment curb. But a heavily used railroad track was just feet away and a derailment could pose an extreme hazard.

Weed learned that BIONOxSOLVER could potentially alleviate all these concerns, and decided to try a trial conversion. Because the product is delivered in ready-to-use totes, CRC personnel don’t handle it. Instead, a worker moves a tote into place and inserts a pickup tube from a metering pump. “With the sodium sulfide chemistry, we had to fill the tank with water and use a mixer motor to dissolve the sodium sulfide flake,” Weed recalls. “This was a very undesirable task, especially during the summer here in Phoenix.”

As a result of the chemical switch, CRC has reduced its labor costs by about 75% by eliminating many of the procedures the former chemistry required. The scrubber is easier to maintain and there is little to no scale buildup. Annual cleaning, required with the sodium sulfide chemistry, has been eliminated.

The company gained additional savings by eliminating protective gloves, aprons, respirators and cartridges required for handling sodium sulfide. Because the new chemistry does not require the 19,000 gallons of water and the electricity for the mixer motor that the sodium sulfide solution needed annually, CRC is saving another $450. The pH operating range was also reduced from prior levels, cutting the amount of caustic used and purchased.

“Converting to the new chemistry was completed in a weekend,” Weed says. “As a result of the conversion’s ability to help us reduce an on site hazardous material, we accomplished a pollution prevention goal that we set with our state EPA office.” The new chemistry also virtually eliminated health and safety risks to employees, he added.

Related Content

Masking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreSilica-free Abrasive Compounds Offer Improved Health, Safety

Osborn has a line of silica-free abrasive compounds that offer both employee and environmental benefits.

Read MorePrecision Coating Receives ISO 14001 Certification

The company says its commitment to the environment and its health led it to seek this certification.

Read MoreEngineered Coatings Offer Improvement for Medical Device Manufacturers

Diamond electroless nickel coating provides better lubricity and improved wear resistance for molds, resulting in better quality and productivity.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More