Chromium Plating Replacement

New barrel plating process can replace chromium plating at half the cost...

From the company's beginnings as a small job shop in 1959, to its current position as a leader in the metal plating industry, integrity, quality and service have always been the driving force behind Master Finish Co., Grand Rapids, Michigan.

Today, Master Finish continues to provide high-quality workmanship by investing in the latest plating technologies. The company is commit-ted to providing 100-pct customer satisfaction.

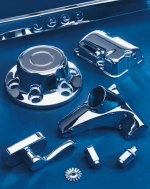

One new technology is a barrel plating process that can replace chromium plating at half the cost, according to Dale Mulder, company president. The new plating technology allows an alloy with a bright chromium-like color to be deposited using barrel plating. Until this technology was available, small steel and brass components that required a bright decorative finish had to be processed on Master Finish's rack plating lines.

Key blanks, small hardware components such as drawer pulls, and small hand tools such as sockets are just a few of the products that are good candidates for this process. According to Mr. Mulder, "This is not just a new twist on existing technology, but actually a significant advance." He says that his company has saved customers nearly 50 pct off the cost of the usual rack plating process.

| TABLE I — Enloy Ni-150 Salt Spray Test Results | ||||

| Steel Panel, 0.2 mil nickel | ||||

|

Hexavalent Chromium | EnloyTM Ni-150; no passivate | Enloy Ni-150; with passivate | Trivalent Chromium |

| 8 hours | No Corrosion | Blue Tarnish | No Corrosion | 10 pct Rust |

| 24 hours | No Corrosion | Blue Tarnish | No Corrosion | 40 pct Rust |

| 48 hours | 2 pct Rust |

|

No Corrosion | 80 pct Rust |

| 96 hours | 50 pct Rust |

|

No Corrosion |

|

| 120 hours |

|

1 pct Rust | No Corrosion |

|

| 550 hours |

|

|

1 pct Rust |

|

The barrel process is effective for three reasons: 1) Parts can be plated in large quantities, reducing labor costs; 2) Specially designed racks are not required; and 3) Waste treatment is simplified, because chromium is eliminated.

Although most electroplated metals can be deposited using either rack or barrel processes, chromium will not deposit properly without continuous electrical contact with the workpiece. The slurry action of parts rotating in a barrel does not allow the electrical contact that decorative chromium electroplating requires.

| TABLE II — Enloy Ni-150 Operating Conditions | |

| Temperature | 140F |

| pH | 6.3 |

| Cathode current density | 20 asf |

| Anode current density | 10 asf |

| Voltage | 2 to 15 volts |

| Time | 8 min |

| Surface tension | 52dynes/cm |

A research team at Enthone-OMI Inc., developed a proprietary nickel alloy plating process that provides the appearance of bright chromium plated deposits. Master Finish Co. plates a nickel strike followed by the Enloy® Ni-150 electroplate onto steel and brass components. Although components with class "A" surface requirements are not good candidates for barrel plating, most other components can be processed with this method.

The process produces a metallic alloy electroplated coating for use over nickel-plated substrates. When used in conjunction with the proprietary passivate, the deposit yields a chromium-like finish with excellent corrosion resistance (Table I). Bath operating conditions are outlined in Table II.

The plating process demands detailed care and meticulous testing. Master Finish uses state-of-the-art plating facilities and highly skilled master technicians. The company adheres to advanced statistical process controls, including compliance with ISO/QS 9000 standards. These rigorous quality standards, along with its in-house laboratory guarantee high-quality finishes.

The company statistically monitors raw materials consistency. Plating bath solutions are also continually monitored. Testing procedures and controls include x-ray fluorescence coating measurement; microscopic metallographic examination; CASS corrosion testing; Kocour plating thickness analysis and step testing; statistical plating bath monitoring; monitoring of raw material consistency and finished product quality.

The company has always strongly believed in responsible waste control. All the company's environmental standards exceed those of local, state and federal regulations.

The waste control system complies with ISO 14001 standards and includes treatment of hazardous solutions, as well as environmentally safe recycling. Residues become raw material for smelting stainless steel. This process keeps all heavy metal by-products out of landfills and streams.

Related Content

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreNanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

Read MoreAn Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

Read MoreHow to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More