Road and bridge infrastructure and its investment must continue to be a major focus of the Federal Highway Administration and state Departments of Transportation (DOT). Continuous improvements made ensure the success of the economy, given that 2.9 million tractor-trailers are on the road daily,

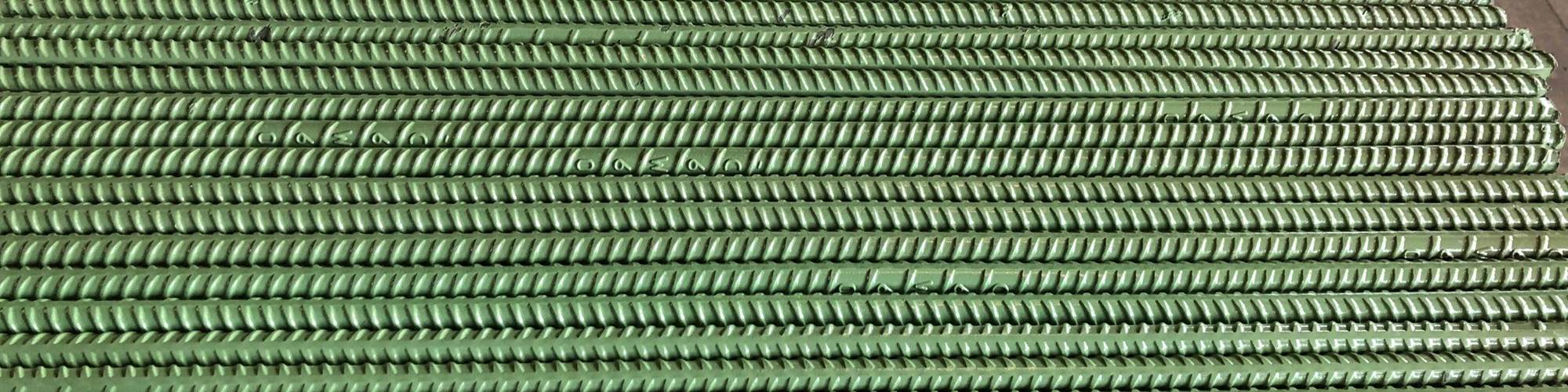

In 2021, the Infrastructure Investment and Jobs Act was signed into law and is the largest dedicated bridge investment since the construction of the interstate highway system. The bill dedicates $350 billion for the investment in highway programs for five years. The epoxy powder coating industry should benefit greatly through the supply of the epoxy-coated rebar used in these projects. Each year, more than 600,000 tons of this rebar are produced in the U.S. and Canada.

Photo Credit: Getty Images

according to the Bureau of Transportation. Although there are several products that protect the reinforced bars (rebar) used in concrete infrastructure from corrosion, one product stands out from the others.

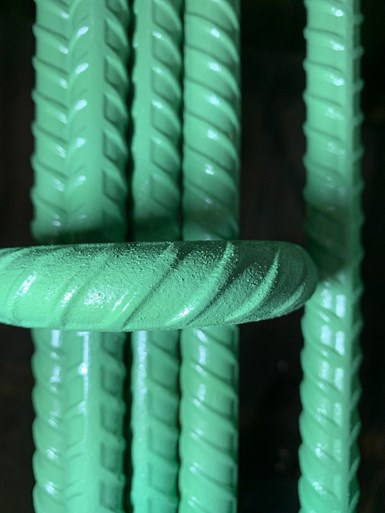

Epoxy-coated reinforcing steel, such as Fusion Bonded Epoxy coated bar, meets industry quality standards for coating thickness, corrosion resistance, flexibility and coating continuity and possesses a long lifespan when used for building roads and bridges.

Prior to understanding the necessity of corrosion-resistant materials, deicing salts were introduced to roads without consideration of their negative implications. In the 1940s and ‘50s, the product was first implemented to combat the safety threats to drivers on the roadways from snow and ice.

During the next 20-plus years that followed, the Federal Highway Administration realized that the deicing salt began to corrode the steel within the concrete bridges and pavements. After performing extensive studies of the problem, the University of Kansas Center for Research found the chlorides (deicing salts) were penetrating through micro-cracks in the concrete and attacking the protective passive layer formed by the steel after the concrete had been poured. This passive layer quickly breaks down once the chloride threshold has been reached (uncoated steel is 1.58 lbs/cubic yard).

Pumping the Brakes on Destruction

The next step was developing a solution to slow the corrosion of these steel

bars. This time using epoxy-coated reinforcing steel, 7.28 lbs/cubic yard of chloride was required to initiate corrosion in the same University of Kansas study. Following the lead of these promising results, in 1973 the first bridge was constructed in West Conshohocken, Pennsylvania, using epoxy-coated rebar.

Then in 1981, standards were developed (ASTM A775 and ASTM D3863) to ensure high-quality epoxy-coated rebars were being supplied and handled properly in fabrication shops and construction job sites.

Over the past 40 years, these standards have been revised to enhance the performance of epoxy-coated steel. The industry also established the Fusion Bonded Coaters Association (FBCA) in 1982 with the goal of promoting and marketing the product. In 1985, FBCA merged with the Concrete Reinforcing

Prior to 1973, many bridges were built using bare carbon steel. As of today, there are more than 600,000 bridges in the United States, of which 7.5% are deemed structurally deficient. This equates to the limited use of more than 45,000 bridges every day by both passenger vehicles and tractor-trailers. Photo Credit: Getty Images

Steel Institute (CRSI) to form a technical standard developing organization to become the authoritative resource for information related to steel-reinforced concrete construction. In 2008, a new group was formed within CRSI called the Epoxy Interest Group (EIG). The group promotes and markets the use of epoxy-coated steel within the concrete construction industry. EIG consists of steel producers, epoxy powder applicators, bar fabricators and epoxy powder manufacturers. As of 2010, this group has provided epoxy-coated bars for more than 65,000 structures over the past 37 years, according to a study by David McDonald, Ph.D.

Unfortunately, prior to 1973, many bridges were built using bare carbon steel. As of today, there are more than 600,000 bridges in the United States, of which 7.5% are deemed structurally deficient. This equates to the limited use of more than 45,000 bridges every day by both passenger vehicles and tractor-trailers.

In 2021, the Infrastructure Investment and Jobs Act was signed into law and is the largest dedicated bridge investment since the construction of the interstate highway system. The bill dedicates $350 billion for the investment in highway programs for five years.

There are more than 30 certified epoxy applicator companies that ensure every ton of epoxy-coated steel meets the industry quality standard set by ASTM A775 or ASTM A934. Photo Credit: IFS Coatings

This bill offers the opportunity for many businesses to help rebuild America’s infrastructure, which should result in greater demand and more jobs. The epoxy powder coating industry should benefit greatly through the supply of the epoxy-coated rebar used in these projects. Each year there are more than 600,000 tons of this rebar produced in the U.S. and Canada.

Living Up to High Standards

There are more than 30 certified epoxy applicator companies that ensure every ton of epoxy-coated steel meets the industry quality standard set by ASTM A775 or ASTM A934. Annually, each of these plants volunteers for a quality certification process where an audit is conducted by the CRSI. This certification process assists the individual state DOT in knowing their specified epoxy-coated rebars are of the highest quality.

Based on many studies by a variety of research institutions, epoxy-coated reinforcing steel ensures these concrete bridges and structures have a minimum lifespan of 75-plus years. According to the EIG, the quality and corrosion resistance that this type of steel provides is also low cost. In addition, this rebar has been used for almost 50 years, offering many examples of quality.

Other Anti-Corrosion Solutions

When designing a bridge deck, continuous concrete road, parking structure, and so on, where corrosion resistance is required from the concrete reinforced bars, there are a variety of products for the owners, architects and engineers to choose from. In addition to epoxy-coated rebar, there is stainless steel, galvanized steel and even glass fiber-reinforced polymer bars offered as corrosion solutions.

When choosing the type of corrosion reinforcement, there are some important considerations. Availability, corrosion performance and cost are typically the most important to the decision makers in this process.

According to a study in 2011 by the University of Kansas, stainless steel type 2205 has been shown to demonstrate the best performance regarding corrosion resistance. It yielded a chloride threshold of 26.4-lbs/cubic yards versus 7.28-lbs/cubic yards for epoxy-coated bar. A couple of the challenges to using stainless steel are the limited number of producers in the U.S. and high cost: With an estimated 100-year service life, stainless steel’s life cycle cost is around $320/square yard, compared to epoxy-coated rebar at $237/square yard.

As for galvanized bar, the American Galvanizer Association states that more than 500 bridges used the hot-dipped version for corrosion protection. It also estimates at least 75 years of service life. Pennsylvania DOT inspected a bridge built in 1973 that used galvanized bar where it yielded a chloride threshold ranging from 1.8 to 7.9 lbs/cubic yard and exhibited no signs of corrosion. However, one of the challenges of using galvanized bars is during fabrication (bending of bars in a shop). During this process, it can lose adhesion to the steel, compromising corrosion protection.

Glass fiber-reinforced polymer is a relatively new technology in the construction business and still has not been widely accepted for use in bridge decks by the DOT. However, due to the non-corrosive nature of this product, it is popular in residential construction, such as foundations, swimming pools, sidewalks and curbs. It is also used in dams, parking garages, piers and seawalls. Water absorption and the freeze/thaw cycle that can affect its strength are some of the concerns for building with this product.

There are a number of products to choose from when corrosion protection is of the utmost importance. However, epoxy-coated bar is widely accepted and successful product for building roads and bridges that protect against corrosion.

About the Author

Rob Phillippi has worked in the powder coating industry for over 25 years and more specifically, the rebar market for the past 15. Phillippi has held a variety of positions, from operations, to technical support, to sales before his current role as a market manager.

Related Content

Quick Turnaround is Key for Architectural Coating Shop

This California metal fabricator and coater focuses on fast turnaround and streamlining its processes with 40 years of experience in the construction industry.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreAromatic Thermosetting Copolyester: Many Forms, Many Uses

As a coating or additive, unique polymer improves bearing wear, protects metals from corrosion under extreme conditions.

Read MoreEpoxy Rebar Company Reinforcing Roads of the Future

Providing epoxy-coated rebar with the ultimate corrosion resistance is Simcote’s focus for the infrastructure industry it serves.

Read MoreRead Next

Finishing Temperature-Sensitive Material with UV Powder Coating

Quality issues with pre-finished components led Global Building Products on a search to discover a new solution for its temperature-sensitive materials.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MorePowder Coating and Green Building

How powder coating can aid architectural applications in achieving environmental certifications.

Read More

.jpg;maxWidth=300;quality=90)