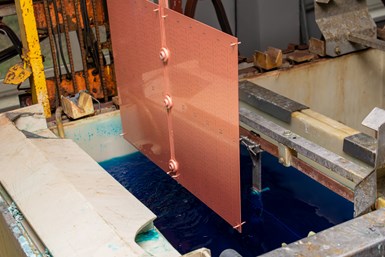

Copper Plating on Aluminum and Aluminum Alloys

How can I plate copper on aluminum?

Q. How can I plate copper on aluminum?

A. A typical process for plating copper on aluminum is:

- Degrease.

- Soak clean.

- Thoroughly rinse.

- Dip in a 50 percent nitric acid solution. Depending on the aluminum alloy, sodium bifluoride, sulfuric acid or chromic acid may have to be used in conjunction with nitric acid.

- Thoroughly rinse.

- Dip in a zincate bath for 1 minute. (Proprietary zincate solutions are best.)

- Strip the zinc coating using 50 percent nitric acid

- Rinse thoroughly.

- Dip in the zincate solution again.*

- Rinse thoroughly.

- Apply a copper strike using a cyanide or non-cyanide alkaline strike bath.

- Rinse thoroughly.

- Plate in a copper plating bath.

* Double zincate is always the recommended procedure for getting good adhesion to aluminum-based materials.

You can find many more details for this process by searching PFOnline.com for “plating on aluminum.” This search also will provide information for plating other metals on aluminum as well.

Related Content

-

Solvent Versus Aqueous: Busting the Myths

Is aqueous cleaning “greener” than solvent cleaning? Is solvent a more effective cleaner than aqueous? These and many other questions are answered here to debunk the misconceptions that many manufacturers have held onto for years.

-

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

-

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

.jpg;maxWidth=300;quality=90)