The best way to efficiently control production processes in the automotive industry is through the use of relevant, up-to-date, and transparent key figures, according to Dürr Systems Inc. (Southfield, Mich.). The company recently launched DXQbusiness.intelligence, a new application in its DXQcontrol portfolio for control technology designed to provide those key figures. DXQbusiness.intelligence gathers data from factory control systems and produces easily-readable reports and clear visualizations, according to Dürr. These reports and visualizations are stored in a specialized data warehouse away from the factory operational system, allowing factory managers to examine the data without stressing the production line.

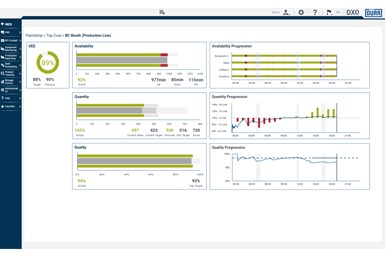

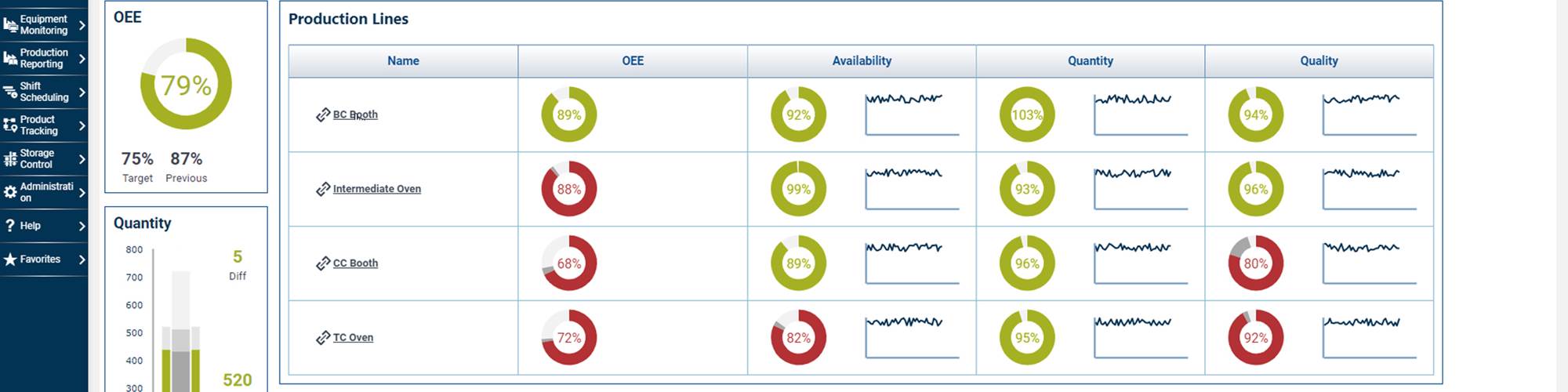

DXQbusiness.intelligence’s production line dashboard preset shows the overall equipment effectiveness and other key information about the user’s production line. Photo Credit: Dürr Systems Inc.

Records of Key Data

DXQbusiness.intelligence is set to provide mission-critical data on one screen. It displays the production data in a dashboard that is designed to be clear and easy to understand. Additionally, the data warehouse server is automatically set to store long-term data across division boundaries, allowing managers to examine historical trends whenever they choose.

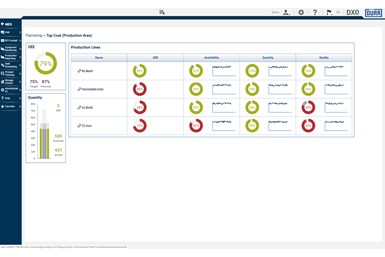

The production site dashboard displays an individual production area’s overall equipment effectiveness. Photo Credit: Dürr Systems Inc.

Organized to support data-driven decisions

Managers using DXQbusiness.intelligence can focus on the data they need, from site-wide statistics to specific production areas to individual lines. For production, overall equipment effectiveness, quality and quantity data are default key data options for production views. When focusing on individual lines, the software displays these figures over time for the selected line.

Through the production area dashboard, managers can inspect availability, overall equipment efficiency, quantity data and quality data within a production area. Photo Credit: Dürr Systems Inc.

Adaptable to individual needs

In addition to DXQbusiness.intelligence’s built-in reports, managers can create and arrange custom reports according to their personalized needs and priorities at any given time.

Related Content

-

5 Things to Know About XRF Calibration

The proactive approach of validating measurement performance and calibrating only as often as necessary improves quality, consistency and reduces costs.

-

Powder Coating Overcomes Post Forming

Six Sigma methodology, open communication, and collaboration produce results for leading boat manufacturer.

-

Titrations: To Automate or Not to Automate?

What considerations should you keep in mind for automatic titrations? Conor McAnespie of Hanna Instruments discusses the benefits of auto titrators.

.jpg;maxWidth=300;quality=90)