Eisenmann’s E-Cube Simplifies Paint Operations

Paint separation system reduces disposal, maintenance costs.

If you thought paint separation always meant a massive headache and an empty wallet, think again.

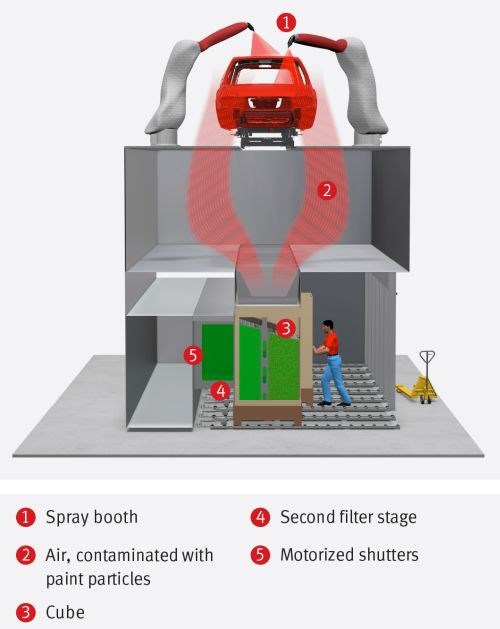

Eisenmann’s E-Cube is a simple, high-capacity paint separation system that operates without the use of chemicals, water or other additives. The E-Cube uses hybrid filters, consisting of surface and depth-type filters that create a labyrinthine flow path, separating paint-contaminated air.

“One of our customers who has been using this system for three months now says with this system, you ‘set it and forget it,’” says Richard Goelz, Eisenmann's Regional Account Manager.

The large filters in the E-Cube system are constantly monitored for airflow with differential pressure sensors to indicate when the cubes are filled. These cubes, which can hold a maximum of 1,300 pounds of overspray, can be removed during production without interfering with the operation of the paint booth. Normal dry filter paint booths have to be shut down before changing filters, but this system is designed with motorized dampers so the cubes can be replaced during production.

The E-Cube is a direct replacement for the venturi scrubber, which required a skilled staff to maintain. In contrast, the E-Cube eliminates the need for a tremendous amount of peripheral equipment, such as a large process tank, chemical feed system, and sludge system, and the operating staff can be unskilled with no chemistry background. The assembly and replacement of the system is relatively simple, reducing maintenance costs and headaches.

|

THE DETAILS |

|

|

Type |

Simple, no additives |

|

Emissions |

0.2-0.9 grains/1,000 dscf (0.5-2 mg/m3) |

|

Pressure Loss |

Rising |

|

Operating and maintenance staff |

Unskilled staff |

|

Overspray capacity |

Max 1,300 lbs |

The E-Cube does not use extraneous water, eliminating not only capacity weight, but disposal costs as well. Because the disposal from a standard system is made of about 40-50 percent of water, the disposal costs, which are dependent on the weight of the disposal, are high. The resultant waste from the E-Cube is about half the weight, Goelz said, reducing the disposal costs. In fact, some of the key goals for the E-Cube booth are to help the customers reduce disposal costs, achieve zero landfill and reduced carbon footprint.

“Many waste handlers like the idea of getting the E-Cubes to convert waste into energy,” says Goelz. “Paint has a very high caloric value, so when it is burned, it creates a tremendous amount of energy. E-Cube’s disposal can be converted into energy, to enable our customers to lower their disposal costs even further.”

The cubes are made of mostly recycled materials and can be folded during storage and delivery to save space.

For more information about the E-Cube, please visit eisenmann.us.com.

Be a Products Finishing Innovator Contact Jess Larkin, jlarkin@pfonline.com to highlight your latest innovations in finishing.

Related Content

-

Cobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

-

Intumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

-

Robots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

.jpg;maxWidth=300;quality=90)