Finishing activity contracted again in January, Closing at 45.5

Finishing activity has shown encouraging signs the past two months, the longest ‘stretch’ since starting to contract in April 2023.

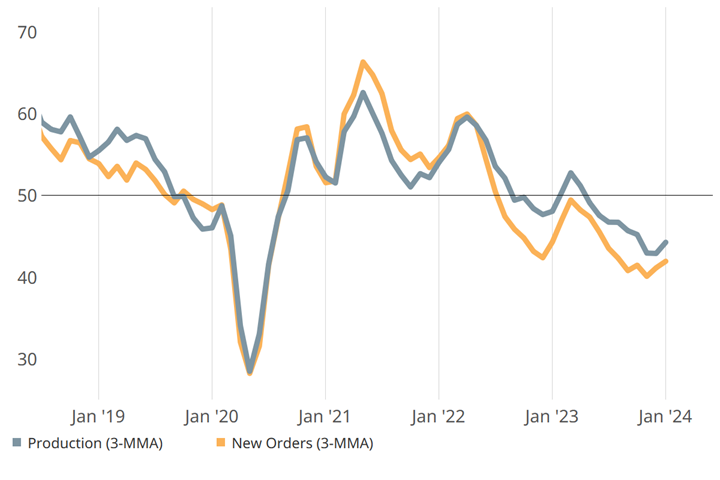

The Gardner Business Index (GBI): Finishing started the new year sustaining the marginally encouraging reading that ended 2023.

- New orders and production slowed contraction in January, while other components held steady, the combination driving the overall index.

- Employment in finishing has contracted at an accelerated rate since September, potentially a correction since growing steadily for months post-Covid.

- Supplier deliveries started to lengthen from being flat in December, generally a sign that business is picking up.

- Optimism about future business, while not part of the GBI calculation, continued to increase in January, likely a combination of improved components and the hope a new year typically brings.

The Gardner Business Index (GBI): Finishing

Finishing activity slowed contraction for the second month in a row.

Key Component Activity

Slowed contraction in new orders and production drove January’s finishing index while optimism around future business increased again.

Related Content

-

Surface Preparation for Best Adhesion for Powder Coating

Kevin Biller with ChemQuest recommends the proper way to prepare a surface for powder coating that leads to excellent adhesion on 304SST.

-

10 Anodizing Best Practices

Following this list of guidelines can help to increase the performance, cost effectiveness and quality for your anodizing operation.

-

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

.jpg;maxWidth=300;quality=90)