Finishing Index Gains Due to Broad Activity Expansion

The Finishing Index is 47.5 as the ongoing slump in business conditions is not universal to the finishing industry. Firms with more than 250 employees have reported expanding conditions since June.

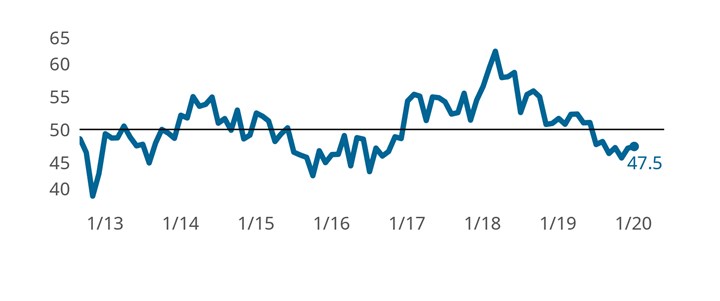

Finishing Business Index

The Finishing Index remained in contractionary territory with a January reading of 47.5. Business activity as reported by survey respondents reported its seventh consecutive month of contracting activity.

The Finishing Index at 47.5 began 2020 reporting its seventh consecutive contractionary business activity reading. Index readings above 50 indicate expanding activity while values below 50 indicate contracting activity. The further away a reading is from 50 the greater the magnitude of change. Gardner Intelligence’s review of the latest data found that the Index was supported by expanding readings for production, supplier deliveries and new orders. The Index (calculated as an average of its components) was restrained by contracting activity in backlogs, exports and employment.

The ongoing slump in business conditions is not universal to the finishing industry. Firms with more than 250 employees have reported expanding conditions since June. However, smaller firms of all other size categories have reported more volatile business conditions in recent periods. The multimonth trend among smaller sized firms continues to be one of either unchanging or contracting business activity.

Finishers serving the medical, automotive, machinery and aerospace industries all reported expanding conditions on average for the 3-month period ending in January. In contrast, finishers serving the petrochemical and or forming and fabricating end markets reported challenging conditions.

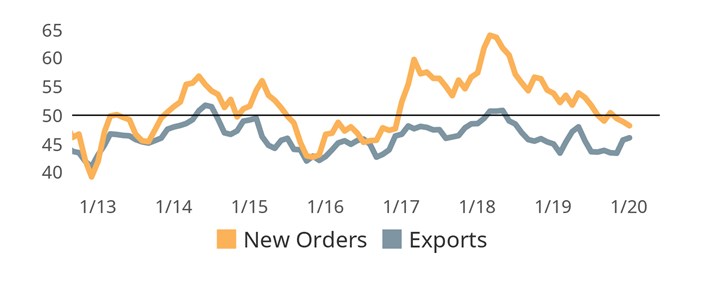

Finishers Report Mild Expansion in New Orders Despite Contracting Exports Activity

New orders posted a slight expansion in January; its first since October. The expansion in total new orders activity coupled with a quickening contraction in export activity implies that finishers experienced strengthening domestic orders.

Related Content

-

Advantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

.jpg;width=70;height=70;mode=crop)