Getting the Right Mix and Avoiding Cross-Contamination in Manual Spray Processes

Payton Cozart, product manager for Carlisle Fluid Technologies, discusses mixing procedures and options for mitigating paint cross-contamination in spray application processes.

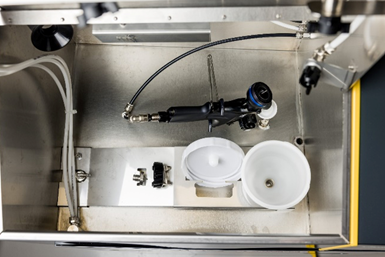

Typical gun cleaner (internal view). Photo Credit: All photos courtesy of Carlisle Fluid Technologies

Q: We paint custom parts using various colors, all with a gravity spray gun, and are challenged with mixing the right amount of paint for each project and preventing one color from cross-contaminating the next job. I am continuously cleaning the gun out and waste a lot of paint and solvent. Are there any better methods or processes that can help?

A: First, let us review the first challenge you highlighted: mixing the right amount of paint per job. Automotive paints are expensive and not going to get less expensive anytime soon. If the target is to reduce costs per job, the first process to look at is how we can minimize mixed paint usage to complete that job. Most automotive paints are multi-component, mainly two or three components mixed, creating a stronger paint adhesion via chemical cross-linking for a durable and long-lasting finish.

The main issue when handling multi-component paints is the ‘workable’, in our case sprayable, time you have before that material kicks over and can no longer be used. It is key to only mix the minimal material per job, especially on your higher-cost topcoats such as colored basecoats and layers of clearcoats. This amount is certainly rooted in science, but we believe there is more artistry involved to perfect. Skilled painters develop skills around this over years of spraying different size substrates (parts) with their current application tools. If they are spraying an entire side of a vehicle, they know they need more material mixed (18-24 oz) than if they are spraying smaller parts such as mirrors or bumpers only (4-8 oz). With the skilled painter market shrinking, coating suppliers have also updated their mixing software where the painter can input the vehicle, paint, and size of repair. The software will prepare a recommended volume to complete each job.

Regardless, a simple audit you can perform is measuring the wasted material after each job. There will always be some waste as you cannot choke the gun’s supply of paint, but if there is significant waste after each job, work with the painter to mix smaller volumes. There is no issue with mixing more material as needed in smaller batches other than some additional process time for the operator to mix another batch. This should be less than the cost of a large volume of wasted but good material.

The second challenge you have highlighted is the cross-contamination of paints from one job to the next. This can also be a high-cost issue as it may not be noticed when painting but is evident when material is cured, requiring re-work, potentially doubling your expense into the job. The only way to ensure this does not occur is to improve equipment cleaning and maintenance between jobs. Both mixing and application equipment needs to be thoroughly cleaned and inspected by the operator to ensure all product surfaces interfaced with paint materials are cleaned after each project. Because this is so significant for right-the-first-time finishing, we notice a lot of shops overusing cleaning solvents and/or flushing materials to ensure all equipment is free of paint and debris. Now, this is not necessarily the worst-case scenario, but excess solvent usage adds to job expense just as unneeded mixed paint. There are a couple of products that should help reduce needed solvent and or cleaning material:

Disposable cup system

Disposable Paint Cups

If you are using hard cups for your topcoat guns, migration to disposable cups will reduce solvent usage and eliminate the cup’s ability for cross-contamination. Disposable cups are replaced for each job, and once all material is consumed, they are properly disposed of, not requiring cleaning for the next job. Even though these tools are coined ‘disposable,’ they still have storage techniques that allow them to be used more than once for materials with longer workable life.

Gun Washers

These tools are usually installed within the mix room where paint is prepared for jobs. They range in size and capability but are designed to properly flush and clean spray guns exposed to solvent-borne materials, water-based materials, or both! These units have manual and automatic cleaning cycles, allowing the operator to focus on other tasks, depending on the model. Units with an automatic wash cycle perform similarly to a dishwasher you may have in your kitchen. The operator places ‘dirty’ equipment within the wash bay, closes the lid, and presses the button/switch to start the automatic cleaning cycle. Each unit runs for a designated amount of time, during which an assortment of nozzles and brushes clean off all contaminated surfaces using recycled media. This recycled media technique keeps overall solvent usage costs down and gets the most life out of each gallon of solvent/cleaning media purchased. Depending on the unit, there may also be a manual rinse option that uses fresh cleaning media as a final rinse before preparing the gun for the next job. The benefit of these units not only reduces total solvent usage, but also helps guarantee consistent cleaning of application equipment with shops that have multiple operators.

About the Author

Payton Cozart

Payton Cozart is a product manager for Carlisle Fluid Technologies. Visit carlisleft.com.

Related Content

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreMasking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreZinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

Read MoreRead Next

Powder Coating Spray Guns

Featuring electrostatic spray guns, systems, nozzles and more.

Read MoreWhen to Introduce Automation Into Your Finishing System

Looking to increase productivity for your liquid coating operation? John Owed of Carlisle Fluid Technologies provides examples of how automation can help improve quality and efficiency for paint spray equipment.

Read MoreHow to Keep Your Paint Booth In Peak Condition

Proper cleaning and maintenance are crucial for keeping your finishing equipment running optimally. Bill Day of Global Finishing Solutions discusses 5 ways to keep your paint booth clean and operating efficiently.

Read More

.jpg;maxWidth=300;quality=90)