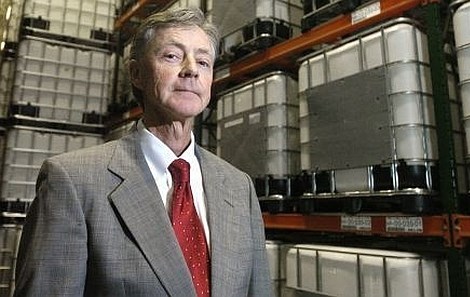

Haviland CEO E. Bernard Haviland

Haviland Enterprises in Grand Rapids, Michigan, a major chemical manufacturing, packaging, and distribution company founded in 1934, is now 100 percent employee owned.

With 220 employees and more than 600,000 square feet of manufacturing space, Haviland Enterprises, is the parent company of two separate divisions: Haviland Products Company and Haviland Consumer Products. Haviland Enterprises had sales of $115 million in fiscal 2012.

Prior to this sale, Haviland Enterprises was owned 54 percent by the Haviland family and 46 percent by Haviland employees. The remaining family stake in the company was sold to Haviland’s “Employee Stock Ownership Plan” trust via an independent team of attorneys, advisors and trustees.

This completes the transition of ownership from the Haviland family to the employees, which began in 1997.

“This sale is consistent with our family’s commitment to the employees and to the communities of Grand Rapids and Kalamazoo,” says Haviland CEO E. Bernard Haviland, the youngest of 12 children of founder J.B. Haviland. “Employee ownership was clearly the optimal path forward for everyone involved. This is an exciting event for the employees, who have always been fully committed to the Haviland legacy of customer satisfaction and solid growth.”

Haviland Enterprises consists of two separate divisions: Haviland Products Company and Haviland Consumer Products. Haviland Products Company formulates, and distributes commodity and specialty chemistry for surface finishing, pharmaceutical and manufacturing companies throughout North America. Haviland Products Company is a contract manufacturer and private labeler for several Fortune 500 companies. Haviland Consumer Products formulates, blends, packages, and distributes more than 85 different swimming pool chemicals to professional pool dealers throughout the United States.

For more information on Haviland Products Company, please call 800-456-1134, or visit Havilandusa.com.

Related Content

-

Products Finishing takes a look at some of the ways the finishing industry is investing in workforce development and educational initiatives.

-

As a Products Finishing Top Shop, this company’s success with offering a variety of finishing services would not be possible without its employee dedication and the pride that’s been instilled in them to produce quality products for its long list of customers.

-

PF is looking for 40 individuals under the age of 40 who are making a difference in the world of coating and finishing. Deadline for nominations is February 1, 2024.