Hitachi Hosts Free Plating Webinar on Process Control Feb. 25

Products Finishing presents Hitachi webinar on how to monitor and adjust plating line to ensure high quality.

Products Finishing is presenting a free Hitachi webinar on Feb. 25 that will focus on helping manufacturers maintain plating process control. The primary topics include:

- Advanced XRF coatings analyzer features for boosting productivity

- Potential time savings obtained from configuration options

- Differences in detectors

- Other analyses an XRF can perform

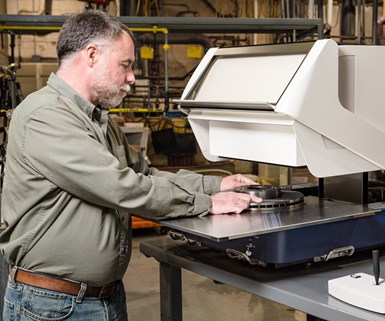

Coatings XRF analyzer

Matt Kreiner, product manager for Hitachi High-Tech Analytical Science’s coating lines, will host the webinar. He will focus on the use of an XRF analyzer as a valuable tool for process control as it enables manufacturers to monitor and adjust plating lines to ensure high quality. The session will explore some of the analyzer’s advanced features and explain their value. Register here.

Related Content

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

-

How to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

-

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.