Index Ends Year with Expanding Supplier Deliveries

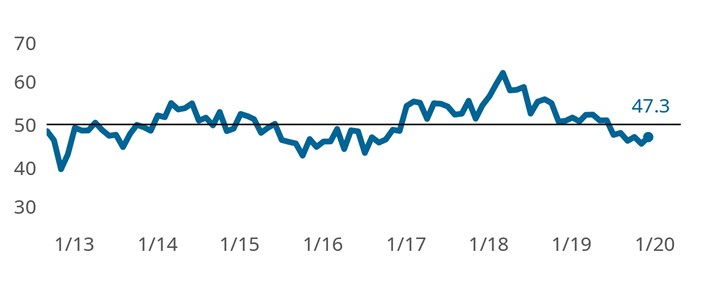

December Finishing Index: 47.3

The Finishing Index ended the year at 47.3, representing a mild contraction in overall business activity compared to the prior month. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50 the greater the magnitude of change. Gardner Intelligence’s review of the latest data found that the Index was supported by expanding supplier deliveries, no change in employment activity and only mild contraction in exports and new orders. The Index — calculated as an average of its components — was pulled lower by a quickening contraction in production and a prolonged contraction in backlog activity.

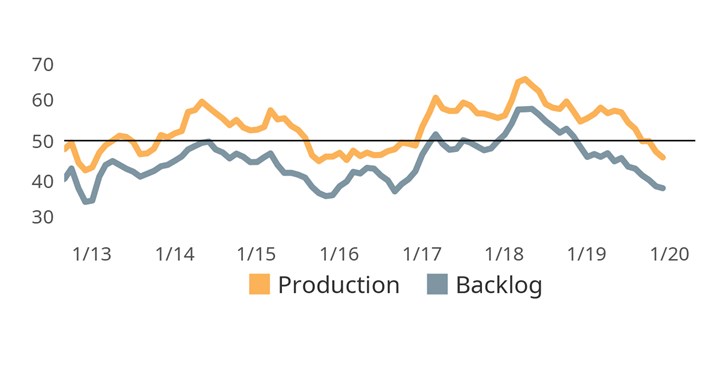

The end of 2019 marked 14 consecutive months of contracting backlog activity. The trend in backlogs during this time has been one of accelerating contraction which registered a fresh low multiyear low as recently as November. The reduction in backlog activity is in part explained by the fact that production readings have exceeded those of new orders approximately 75% of the time since early 2018. Only in recent months has this relationship been reversed. This transposition may potentially signal the start of a rebalance between production and order demand.

Finishing Business Index

The Finishing Index closed the year at 47.3. Expanding supplier deliveries was offset by contracting production and backlog activity.

Backlogs Reported an Accelerating Contraction in 2019

The contraction in backlog activity accelerated throughout 2019. Monthly production readings in the last two years frequently exceeded those of new orders, this in part is assumed to have influenced backlog levels.

Related Content

-

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

.jpg;width=70;height=70;mode=crop)