As electric vehicle (EV) production volume increases, and sustainable, environmentally friendly technology becomes more critical in many industries, businesses that offer any industrial cleaning services in these markets must evolve to meet changes in order to be competitive. John Clark, vice president of E & J Parts Cleaning Inc. (Waterbury, Connecticut), understood this concept especially after attending the Precision Machining Technology Show (PMTS) 2021 in Cleveland, Ohio. It was there that he compared his small family business (which offers only parts cleaning and no other surface finishing processes) to other large-tier cleaning suppliers. As a result, Clark decided it was time to elevate the company’s cleaning capabilities.

Because of the stringent specifications and environmental safety demands encroaching the cleaning industry as well as the high end automotive, medical and aerospace industries in particular, which are the company’s largest customer base, E & J has been taking major steps toward improvement since Clark’s experience at PMTS 2021 and the Parts Cleaning Conference that he attended at the show.

“For us to grow, the question is, how do we become an authority in the marketplace?” he says. “What can we do to lock ourselves into a service that is both valuable and necessary?”

The company’s main 18,000-square-foot facility houses two vapor degreasers, seven vibratory deburring bowls ranging from 2 cubic feet to 22 cubic feet, a small-lot passivation and wax station with a spin dryer, and three tumbling barrels. Source (all photos): E & J Parts Cleaning Inc.

As a small company that specializes in a process that has long been known as an afterthought for many manufacturers, E & J must work especially hard to be considered an expert in technical cleanliness. Recently, it has made bold investments in technology, including the implementation of a paperless ERP system and the purchase of an automated materials microscope for cleanliness analysis. It also has added a cleanroom at one of its two locations, and has an automated vacuum degreasing system on order.

From 2 to 20

In 1993, Clark’s father and mentor, John T. Clark Jr., and the late Everett J. Hardick Sr. opened E & J Parts Cleaning Inc. These two men bravely embarked on forming a metal finishing business based on solid customer service, on-time delivery and no part rejects. Today, upholding the same philosophy, the company has grown to two facilities that equal 24,000 square feet, running three shifts per day and processing over a billion parts per year (25,000 pounds of material per day), with a total of 20 employees.

Although the shop’s customer base is mostly local in Connecticut, where it has about 100 customers, it also draws business from New York, New Jersey, New Hampshire and Massachusetts, and even has a customer as far away as Texas.

Clark recalls that the original shop floor contained one tumbling machine and a hand scooper. “I grew up in this business,” he says. “I used to come in when I was a kid and make boxes, sweep floors and learn from what the guys (employees) were doing.”

Part lots must fit into the company’s degreasing tanks of which the vapor region is about 3 to 4 feet deep. Although cleaning battery cans (shells) is a big part of E & J’s business, the company also cleans brass keys, ammunition components (shells and magazines), blasting caps, fumigation cups and sprinkler heads.

These days, much has changed within the facility’s walls. Clark does way more than box making and floor cleaning. As a company leader, he credits his semi-retired father for educating him about the business and teaching him everything he knows. “My dad has worked 50 years in metal finishing,” he explains. “We would not still be here if it weren’t for him.”

Both father and son have reaped the benefits of their hard work through the years and are grateful for their talented and dedicated team which has led to the business’s prosperity.

Today, the company’s main 18,000-square-foot facility houses two Barron Blakeslee vapor degreasers, seven vibratory deburring bowls ranging from 2 cubic feet to 22 cubic feet, a small-lot passivation and wax station with a spin dryer, and three tumbling barrels. Also, as this article is being written, a Roll automated vacuum vapor degreaser is on order.

The shop, which has earned ISO 9001: 2015 certification and is ITAR registered, mostly cleans high-volume lots of stamped metal parts primarily for the automotive, defense and aerospace industries. These part lots must fit into the company’s degreasing tanks of which the vapor region is about 3 to 4 feet deep. Although cleaning battery cans (shells) of sizes AA, ½ AA, 2/3 AA and D is a big part of E & J’s business as well, the company also cleans brass keys, ammunition components (shells and magazines), blasting caps, fumigation cups and sprinkler heads.

At its second location, a 6,000-square-foot facility in Terryville, Connecticut, the company has spent the past year and a half building an ISO 5 cleanroom that houses its new automated materials microscope. This equipment can identify particulates as small as 5 microns on parts after they have been cleaned. This location also is home to one Branson vapor degreaser.

Starting with automation

For Clark, the first step to advancing the company’s technology was to

Originally, E & J’s customers outsourced their clean parts for testing, which took 6 to 8 weeks to receive the results. Instead of waiting that long, Clark decided to move the process in-house. Hence, the birth of E & J’s ISO 5 cleanroom.

automate the ERP system to be scalable. In the beginning of 2021, he started drumming up an idea for this.

“I knew we needed to be able to process more material more efficiently and keep prices stable to foster growth in this industry,” he explains. “Because we are a service provider, we cannot charge a fortune. We must balance quality with cost.”

Clark integrated an ERP system into E & J’s 9001:2015 Quality Management System later that year. Now, instead of handwriting and job travelers, the shop uses barcodes. When an order comes in, it generates its own unique ID number for that job with all the appropriate information, including the purchase order number, lot numbers and work instructions. Then, the operator “scans out” when they finish a job. This process creates door-to-door traceability.

Clark believes that the use of barcodes has changed his business for the better. “I think the big trend in the parts cleaning industry is traceability, which shouldn’t be a trend; it should be a rule.”

Cleaning up its act

One advantage to attending PMTS 2021 was all the valuable contacts Clark made with colleagues who led him toward considering precision cleaning processes for the business. But prior to that, he had been working on a big EV battery job for a customer that needed ISO 16232 validation. At the time, E & J’s customers sent out their clean parts for testing, which took 6 to 8 weeks to receive the results. Instead of waiting that long for an outside party to do the testing, he decided to move the process in-house.

After countless hours of educating himself about his realization and researching products, he understood the need for a cleanroom as well as a microscope for these technical cleanliness demands from not only his customers in automotive but customers serving other industries that could benefit from the precision cleaning lab as well.

Clark and his team spent the last year and a half building the ISO 5 cleanroom, which involved a lot of research. The highly controlled cleanroom environment is fitted with three HEPA filters/fans and a near zero particulate workbench with its own set of hepa filters and blowers.

“I had never built a lab before, so I needed to make sure it was overengineered,” Clark says. He added that it takes a lot of effort to understand what it means to build a lab as well as reading the 200-page ISO 16232 document. “Reading it is one thing; understanding it is another.”

Building the ISO 5 cleanroom also involved learning a lot about laboratory processes and controls. During that time, Clark and his team developed their own extraction methodology and set up consistent processes, which was critical to the lab’s success.

“We develop a process, we validate the process, and we don't deviate from that process,” Clark explains. “We do it the same way every time. That's what gives us 8,000 to 10,000 orders a year with no rejects, no mixtures, no corrective actions.”

Building the cleanroom was a huge step for E & J’s trajectory toward being a leader in the precision cleaning industry. “The lab is another level that has added value to our business and increased opportunities for us in a way I never thought really was possible just 5 years ago,” Clark explains. “It's an entirely new business and an entirely new set of controls, precision and impartiality.”

Putting cleaning under a microscope

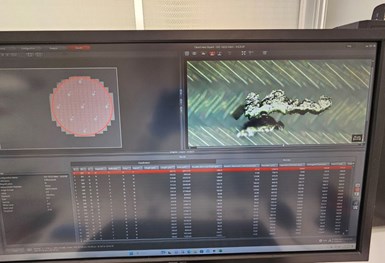

Implementing a microscope system for particle analysis was a critical step to completing the lab. In 2022, E & J received a grant from the state of Connecticut for an advanced, automated, materials microscope from Leica Microsystems that can identify, categorize, measure and photograph particulate contamination after the cleaning process.

This system includes software that generates detailed reports outlining particle size and categorization in compliance with ISO 16232, VDA 19 and other industry cleanliness specifications.

The automated materials microscope located inside the cleanroom identifies particles down to the size of a red blood cell while highlighting larger, critical particles that will cause failures in the end product. While technical cleanliness has come to the forefront of the automotive and e-mobility industries, this application can be a solution to medical component manufacturers as well as aerospace cleanliness challenges.

Clark describes how the lab uses the new microscope that it just began using at the beginning of 2024 for testing. “We perform an extraction method inside the lab after cleaning,” he says. “Then we put the solution through a filter, and that filter gets dried and then analyzed under the microscope.”

The microscope’s software identifies particles as small as 5 microns while highlighting larger, critical particles that can cause failures in the end product.

Evolving with regulations

While adding critical equipment for its growth, the company simultaneously juggles safety and environmental challenges evolving that influence its existing equipment and original processes. E & J’s use of the chlorinated solvent trichloroethylene (TCE) for the past 30 years in its vapor degreasing equipment is in danger of being banned by the U.S. Environmental Protection Agency. Therefore, the company has been preparing to make the switch to replacement solvents for several years now.

Not only are non-chlorinated solvents safer for the environment and the workplace but they are less expensive and require less work. Currently, TCE

With the arrival of the new Roll vacuum vapor degreasing system, the shop can offer safety and regulatory compliance.

usage requires tracking, including measuring emissions and measuring consumption, and following federal and state regulations. The process has also been very costly for the company, especially more recently when the price per barrel went from several hundred dollars to $4,000.

With the arrival of the new Roll vacuum vapor degreasing system, the shop can offer safety and regulatory compliance. The system not only enables integration of the hazardous-free solvents but also allows the business to offer “end-to-end” precision cleaning services at high volume with ISO 16232 cleanliness validation testing for its customers.

Future plans

As E & J begins validating jobs to ISO 16232 this year, Clark is confident that the company will be successful in this endeavor. “This is a milestone achievement for us,” he says.

But in no way does he plan to stop advancing the company forward. When contemplating the business’ future, he explains that it is crucial to evaluate current processes and procedures, learn from mistakes and seek ways to improve. “You must look at yourself and say, where can I get better? Where am I falling short?” Eliminating biases is another key to growing the business, he adds.

In 2024, he envisions the pivot away from TCE to nonhazardous automated cleanliness with automated validation. “And then I’d like to build another cleanroom, get another microscope and another automated cleaning system,” Clark concludes.

More From This Author

Lori Beckman writes about surface finishing and manufacturing cleaning as senior editor of Products Finishing. For more of her work, SUBSCRIBE HERE.

Read Next

Particle Analysis Evolves with Cleanliness Specifications

Cleanliness analysis equipment has become more advanced as testing and reporting particle contamination levels have become more critical.

Read MoreReplacing Open-Top Vapor Degreasing in Aerospace Manufacturing

Options and considerations for cleaning aerospace parts as regulations tighten on vapor degreasing solvents.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More