Selective Finishes

A look at finishing complex parts through selective plating and selective powder coating.

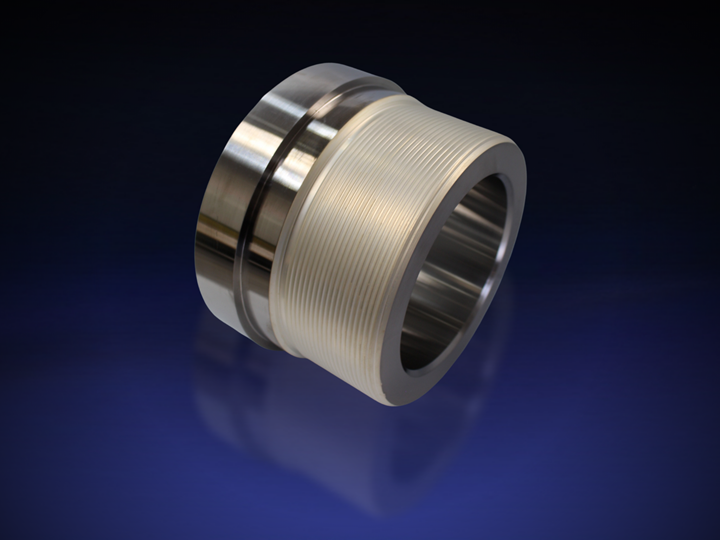

Selective silver plating on a seat control valve.

Photos provided by Luke Copp, sales and marketing associate, Advanced Plating Technologies (Milwaukee, Wisc.)

Advanced Plating Technologies (APT, Milwaukee, Wisc.) is an industry leader in selective plating services of loose-piece products used within a wide range of industries including the bearing, aerospace, medical and petrochemical sectors. Selective plating is offered across APT’s entire line of plating services including gold plating, silver plating, nickel plating, electroless nickel plating, lead plating and tin/lead plating.

Selective powder coat on an electrical housing.

In addition, APT welcomes challenging selective powder coating requirements. The company has refined a wide range of masking techniques and can handle most applications including high cosmetic selective powder coating applications.

Related Content

-

Plating Additively Manufactured Plastic Parts

Using electroplating to enhance the structural properties of 3D printed parts.

-

Women in Finishing Forum Tours Regal Boats

This month’s Photo Finish features a finishing process on a Regal boat.

-

Electroless Nickel On the Rise

ENC 2023 was held in Milwaukee, Wisconsin, offering a wealth of educational programming and networking opportunities for finishers looking to grow their electroless nickel business.

.jpg;maxWidth=300;quality=90)