Test to Find Answers to a Cleaning Solution Dilemma

Finding the best cleaning fluid for a specific application is possible by carrying out practical trials, backed by lab analyses.

Although there is not one cleaning solution that is suitable for all industrial cleaning tasks, finding the best cleaning fluid for a specific application is possible by carrying out practical trials, backed up by lab analyses. Manufacturers must identify the most cost-effective solution for each individual cleaning application. Apart from the actual cleaning method, the entire production process (including the type of machining used as well as the transport and storage containers) must be taken into account.

This article includes an analysis of three cleaning trials where both solvents and aqueous cleaning agents were tested. The results offer a clear picture of the best solution to use for each application.

Plan of Action

Companies should consider creating project teams that include experts from various fields to make the most educated decision about which medium is most appropriate for an application. The chosen medium must be able to achieve the cleanliness specifications at minimum cost. A flexible cleaning unit and a "low-maintenance” solvent are indispensable.

First, companies need to assess the situation, comprehensively and thoroughly, by answering these questions: What materials are the parts made of? What are their geometries? What degree of contamination is likely to occur during production? How clean must the parts be after machining?

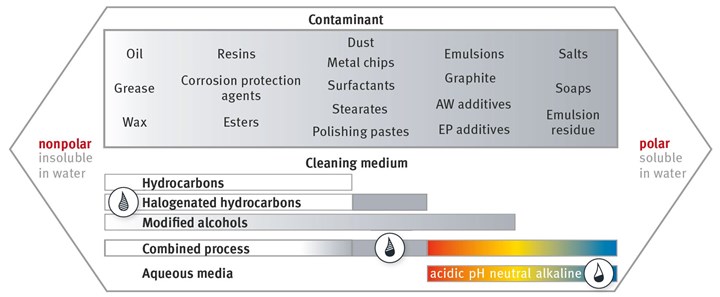

Fig. 1: Contaminants are defined as either nonpolar or polar. The type of contaminant governs which cleaning solution should be used. Hydrocarbon fluids are best used on nonpolar contaminants, while aqueous fluids are best used on polar contaminants.

Apart from particles, contamination can also be found as a film over parts. This film comes in two categories: polar and nonpolar. Polar substances include emulsions and most other aqueous additives, while nonpolar substances include machining oil and grease. By considering this fact, certain cleaning media can be ruled out and the options narrowed down. See Figure 1.

Technical cleanliness requires clear specifications in the form of numbers of particles per part or per defined surface area, classified by particle size (in microns = 1/1,000 mm). Equally relevant are gravimetric specifications (in milligram per defined surface area) and the surface tension (in millinewton per meter). ISO 16232 and VDA 19 describe the general requirements for technical cleanliness and suitable testing methods.

By following these standards and guidelines, manufacturers will soon get a clear picture. They can identify the key issues to be taken into account along the entire process chain and realize that what is theoretically desirable might not be practically achievable.

Test Examples

To find a solution for a cleaning application, it is necessary to perform practical tests in commercial cleaning units, testing all fluids that could potentially be used. If these trials are performed in various models of standard units, the most suitable cleaning process can be identified relatively quickly.

The following examples based on practical experience take into account energy input, costs and fluid consumption.

Example 1: Extruded bushings

- Parts cleaned: Extruded bushings made from aluminum blanks

- Material: Aluminum

- Contaminants: Zinc behenate, which is an auxiliary material used in extrusion process

- Cleanliness specifications: Parts free of particles larger than 200 microns

Several cleaning tests need to be performed, using both non-aqueous and aqueous solutions.

Method A - cleaning with aqueous solution: Cleaning with an aqueous solution in a cleaning unit; single-chamber cleaning unit with two tanks with spray, flooding and optional ultrasound function. The cleaning fluid is acidic (pH 5). Cleaning without additional ultrasound is not successful. This means that ultrasound treatment is a must with aqueous cleaning. The operating cost of this aqueous cleaning system is $4.98 per batch.

Method B - cleaning with solvent: Cleaning within a full vacuum, single-chamber unit with two media tanks, with flooding and optional ultrasound function. The cleaning medium is perchloroethylene (perc). In contrast to cleaning with an aqueous solution, there is no need for ultrasound treatment to achieve the required result. This means shorter cycle times, reducing costs to $3.53 per batch.

Result: When comparing the energy consumption of the two cleaning methods examined here, cleaning with perc is significantly more efficient, using only 3.3 kW per batch, as opposed to 6.0 kW per batch with the aqueous cleaning agent.

Conclusion: Cleaning costs per batch of $4.98 and $3.53, respectively make it clear that treatment with chemical solvent is the economically preferred option here.

Example 2: Control pistons

- Parts to be cleaned: Control pistons, machined, hardened and cylindrically ground prior to cleaning

- Material: Aluminum

- Contaminants: Aqueous compound and grinding additive

- Cleanliness specifications: Parts free of particles larger than 200 microns and no residue on parts

If there are no specific requirements regarding the cleaning solution, and if it is possible to perform trial runs in cleaning units with various solvent types and aqueous fluid, a full picture of all the options emerges.

Some cleaning units require the use of aqueous solutions, such as this Pero-TWT automatic immersion cleaning system. The Example 2 test in this article proves that aqueous agents are most successful when cleaning parts containing polar contaminants.

Result: Cleaning with solvent reveals spots on the parts that were already there before the cleaning process. They have become visible after all oil and grease residue were removed and consist of salt and calcium deposits left behind by the grinding compound. In this case, the principle of cleaning "like with like" applies. To remove polar contaminants that have caused the spots, using a nonpolar product (for example, halogenated hydrocarbon) or a bipolar product (for example, modified alcohol) alone is normally not the answer.

Conclusion: This is a typical example of an application where aqueous agents are the best choice.

Example 3: Wire mesh

- Parts to be cleaned: Wire mesh parts (raw material drawn, annealed and meshed)

- Material: Steel, stainless steel or copper

- Contaminants: Drawing oil (used to reduce friction during drawing)

- Cleanliness specifications: Parts dry, free of oil and grease

As there are no specifications regarding the cleaning solution, trials in cleaning units using different solvents will provide a good picture of the available options.

Result: If an aqueous solution is used, the issue of drying needs to be considered carefully, as large amounts of energy are required to achieve perfectly dry mesh parts.

Conclusion: Given the high energy costs for drying, solvents are the preferred solution here.

Benefits of Each Solution Type

Things become complicated when the parts must not only meet the usual cleanliness and residual contamination requirements but must also be free of spots. To remove salt deposits, soap scum or fingerprints, an aqueous solution is needed. There is, however, the risk that new spots are produced during drying.

In such cases, methods that combine an aqueous solution and nonaqueous solution are the preferred option. These might, for instance, require the use of a solvent for preliminary cleaning, followed by treatment with an aqueous cleaning agent. Depending on the application, these two processes might be performed in a single machine or in two separate units. Again, the issues of processing time and the overall cleaning costs must be considered.

Aqueous solution is often referred to as "strong cleaning agents.” While they require some extra treatment for reuse, they are suitable for a range of applications. Only aqueous cleaning agents are able to modify the surface properties of parts by removing some of the material.

Solvents do not have this capacity, as they are pure chemical substances. They offer, however, outstanding grease-removing properties and are easy to purify by distillation. In addition, they are effective for cleaning parts with complex geometries.

When cleaning parts efficiently, cost reduction is a large benefit.

Cleaning Solution Overview

From time immemorial, water has been used for washing and cleaning, and additives (such as surfactants, builders and preservatives) enhance its cleaning properties. Modern processes with aqueous cleaning agents are run under acidic, neutral or alkaline conditions. To achieve stable cleaning processes, the cleaning fluid must be continuously treated.

This can be done efficiently in systems where solvents are used.

Modified alcohols are the latest addition to the range of available cleaning fluids. They offer a number of advantages, as they contain both polar and nonpolar components and are therefore a viable option for the removal of residue left behind by aqueous emulsions.

For the last two decades, solvents such as hydrocarbons (known as isoparaffins) have become the solution of choice for a range of applications.

Halogenated hydrocarbons, such as perchloroethylene, have been available for even longer and are widely used in many industries for cost-effective parts cleaning and degreasing.

In the process of identifying the best possible cleaning solution for the job, manufacturers must consider the degree of cleanliness that needs to be achieved, as well as ecological and economical aspects.

Pero AG | pero.ag

About the Authors

Thomas Schwarz is a mechanical engineer and works as a technical consultant at Pero AG in Königsbrunn, Germany. Business Economist (FH) Walter Mueck is in charge of marketing at Pero AG in Königsbrunn.

Related Content

Pretreatment of Black Oxide

Having issues achieving a consistent color with the application of black oxide? Start by looking at your pretreatment. Connor Callais of Hubbard-Hall offers advice for troubleshooting your black oxide process.

Read MoreAdvantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

Read MoreClean Technology Lasers for Coating Adhesion

Laser cleaning systems remove corrosion, grease, residue and existing coatings from metal surfaces quickly, with less preparation and mess than traditional techniques.

Read MoreImproving Wastewater Management Efficiency

Don’t find yourself underwater when managing wastewater processes. Follow these steps to improve efficiency and determine the best ROI.

Read MoreRead Next

Cleaning and Corrosion Protection with Solvents

Protect parts against rust in an efficient and sustainable way.

Read MoreThe Right Chemistry Can Improve a Parts Cleaning Process

The correct combination of factors should help you meet production, quality, personnel safety and environmental requirements.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More