The Driving Force for the Ultimate Finish

The Automotive Industry knows the benefits of powder coating and is pushing for an all powder topcoat system. PPG Industries successfully combined a powder basecoat with a powder clearcoat—replacing liquid sprayable coatings to reduce emissions, paint material waste and operating costs. Here's how they did it...

The performance capabilities of powder coatings technology for body antichip primer applications has driven technical advances in powder chemistry towards more advanced and challenging applications—especially for automotive topcoats.

Automotive topcoats, based on powder technology, are now more feasible due to improvements in chemistry, manufacturing and pigmentation techniques. Powder coatings can now deliver the aesthetic and styling capabilities previously only achievable in liquid systems.

Applications such as tu-tone accents, pearlescent tri-coats, tinted clearcoats and striping are not only possible with powder but are made more manufacturing-friendly by powder technology. Hybrid systems, which combine liquid clearcoats over powder basecoats, further enable customers to implement powder topcoat technology in a controlled, manageable strategy. Customers are able to migrate from today’s powder primer applications towards tomorrow’s all-powder topcoat systems with confidence.

The Journey from Functional to Decorative Powder Coatings

Powder coatings proved their value for many automotive applications long ago. Powder-coated parts are found in many sub-assemblies for exterior, interior and under-the-hood applications and full body primer has been a very successful application for domestic OEMs.

The simplicity and consistency of powder coating applications appeal to the professionals responsible for setting up complicated software brushing programs. Their ease-of-use benefits the maintenance specialists who keep the distribution and recovery systems and powder booths at maximum efficiency. And the film properties of today’s automotive powders set a gold standard for VOC emissions, durability, abrasion, chip resistance and many other attributes. With such a glowing resume as this, an OEM-market pull for expanding powder coatings into more demanding decorative applications was inevitably established.

The challenges for decorative coatings are much more demanding than for functional coatings. Decorative coating performance essentially requires all the performance attributes of a functional coating and further requires excellence in appearance aspects such as gloss, smoothness, brilliance and pigment reflectance.

Although powder coating chemistry has advanced to the point where an acceptable level of many of these attributes is possible, all attributes must be delivered before any action can be taken.

For example, achieving a satisfying response in pigment behavior has been lacking. Also, the particulars of balancing attribute performance with powder flow and application properties have been holding back the advance of powder technology as automotive topcoats.

In short, “make it look and act like liquid” is easy to say—but not quite so easy to do.

Along the development path to all-powder topcoat systems, PPG has pioneered several crucial proprietary tools, which were necessary to meet the challenges presented by this opportunity. New methods of defect analysis, particle behavior, pigment incorporation and process control have combined to open the door for powder technology as the “End Game” for automotive topcoats.

Decorative Challenges

As powder coatings welcomed expanded automotive application opportunities, the supporting equipment industry also felt the customer pull to improve application technology.

Venturi pump systems have been made obsolete by dense-phase gentle transfer of powder material. Ultra-sonic fine sieving of powder has improved defect control and powder flow. In addition, bell applicators have replaced traditional conical or designed geometry nozzles to improve film uniformity and reduce applicator density and capital cost. Reclaim systems now typically achieve more than 95% material use efficiencies on an everyday basis.

For powder technology to step-up the application ladder to decorative topcoats, none of these gains in equipment and system benefits could be compromised.

Early development efforts of powder technology as automotive topcoats involved the simple incorporation of aluminum, mica or similar effect pigmentation used by liquid coatings. The results were generally acceptable for mechanical film properties but stopped well short of meeting the challenge of equal-to or better appearance than their liquid counterparts.

In addition, when these compositions were subjected to the rigorous tests developed to screen application system compatibility, the results were totally unacceptable – film defects were being created by the interaction and electrostatic behavioral differences of effect pigmentation and powder binder.

Appearance isn't everything...but it plays a major role

The appearance behavior of automotive topcoats is a very specialized science, engineered to give the exact dramatic effects that the OEM styling professional visualizes in their concept colors. The brilliance and lightness-darkness “travel” of the coating, for example, are critical to achieving the desired total look from any viewing angle.

Equaling the behavior of liquid coatings with powder technology in these attributes is a considerable challenge, given the chemistry and physics differences in how the two technologies flow, level and react. Simple swapping of liquid pigmentation into powder bases was not going to meet the challenge—another way had to be developed.

Application Woes

The introduction of powder bell applicators benefited the OEM customer by improving film build uniformity across the target vehicle surface. Better film uniformity in turn improved the overall appearance of powder coatings, as variations in flow or leveling due to film build were virtually eliminated.

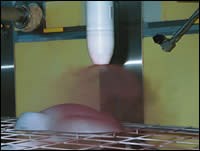

The ability to achieve equal appearance on both horizontal and vertical surfaces—a distinct advantage of powder coatings over liquids—now could be realized. However, the new smooth and level films also highlighted a new type of defect created by the combination of powder particle geometry and the electrostatic and particle flow physics of powder bells. This new defect looked like a small coalesced sliver or skin of powder and became known as a powder “eggshell.”

Powder eggshells and their derivatives have been conquered in today’s full-body primer applications where powder bells are used but in early testing with powder-based topcoats, the eggshell defects returned. Again the cause seemed to be the interaction of the powder base with the effect pigmentation. Careful analysis of this phenomenon slowly led to the discovery of how to prevent the defect from occurring. Simple incorporation of liquid-based pigmentation into powder bases would not meet the challenge – another way was needed.

Manufacturing the Powder

The process of manufacturing powder coatings is one of controlled-engineering, similar to many other designed chemistry products. The step up to manufacturing powder coatings for exterior body application is, for example, a dramatic move in process control and equipment specialization. The new challenge of producing powder coatings to the standards required of automotive topcoats requires a deeper and thorough understanding of which aspects of the manufacturing flow should be broken apart, and how the variables of the new segmented process steps should be controlled.

Putting it all together

PPG calls its powder topcoat development program P2Zero®. P2—for powder basecoat combined with powder clearcoat and Zero—for zero waste and VOC emissions. The P2Zero coating process uses PPG’s existing Enviracryl® powder clearcoat in combination with the newly developed Envirocron® PZB (Powder Zero VOC Basecoat) powder basecoats.

PPG has also developed specialized equipment, process techniques and knowledgeware in manufacturing the PZB generation of powder coatings designed for application as automotive topcoats. The Spindel® powder manufacturing process incorporates the knowledge and tools developed during the PZB development phases to achieve the quality level needed to meet the challenges of automotive decorative topcoats.

Achieving the "End Game" Results

The new basecoats have retained the excellent application properties and low defect levels of the company’s popular Envirocron powder antichip primers. The basecoats rival the appearance qualities of liquid counterparts and are fully reclaimable in today’s distribution systems. Since the basecoats are derived from their primer predecessors, they are fully functional as high-durability antichip coatings and can also be clear coated with a wide variety of liquid clearcoats, for additional material and process flexibility.

Many OEM customers have a very defined vision of what their coating “End Game” criteria would be. Coatings system metrics including appearance, durability, cost, environmental compliance and others are frequently part of their equation.

Powder coatings have long held the promise of delivering 100% of what can be measured in several of these metrics but by falling short on others, have been relegated to implementation as workhorse antichip primers or decorative coatings for interior, exterior or under-hood components.

With the development of powder coatings and the powder manufacturing process, PPG has delivered performance in all of the End-Game metrics and has elevated automotive powder technology securely into contention as decorative full body topcoats.

Related Content

Top Shop’s Journey to Building a Unique Brand

Since this new Ohio plater took over the space and assets of a former plating business, it is intentional about setting itself apart from prior ownership.

Read MoreEpoxy Rebar Company Reinforcing Roads of the Future

Providing epoxy-coated rebar with the ultimate corrosion resistance is Simcote’s focus for the infrastructure industry it serves.

Read MoreRobots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

Read MoreFinishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)