The Real Cost of Downtime

Making the right color-change decision in powder coating operations.

Powder coating provides industrial finishers high-quality, durable finishes for a countless array of products along with the added benefits of improved efficiency and maximum compliance with environmental regulations.

While there’s no question powder coating offers a number of advantages, there are a number of questions to ask in deciding which type of powder-coating operation is right for you. In today’s lean manufacturing environment, downtime can be expensive. That’s why one of the biggest questions to answer is whether to reclaim powder or spray to waste.

Spraying to waste may seem to contradict one of the major benefits of powder coating—namely the ability for coating overspray to be readily retrieved and reused—but depending on your situation, it might actually be more cost effective. Companies have developed a number of computer modeling tools to help in evaluating various options and variables in making the decision. Below, you’ll find examples of a few different scenarios that demonstrate the cost differences between traditional color changes, fast color changes and spraying to waste with color on demand.

Technology Changes the Picture

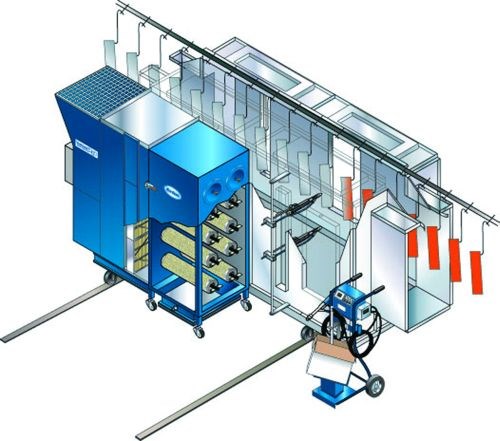

Concurrent with the technological advancements made in powder coating are new and innovative ways to apply the powder, and improve powder-application efficiency. For some time, powder-coating options have ranged from small, manual batch systems to fully automated multi-booth, roll-on and roll-off fast-color-change systems.

Current technology eliminates the need for additional powder booths and color modules for each color sprayed. This saves floor space, energy and capital investment and provides the flexibility to spray any color without purchasing new equipment. Current technology also provides for color changes in as little as 5–10 minutes with powder reclaim systems and 20 seconds in non-reclaim systems.

Color changes of less than 20 seconds were not even an option just a few years ago, but new technology allows for changing color on the fly with near instantaneous agility. There are also new spray guns employing “dense-phase” powder delivery that can achieve more than 70 percent first-pass transfer efficiency. Not only does this provide excellent powder coverage for difficult parts, but it also dramatically cuts down on the amount of powder used—and wasted.

Like liquid paint kitchens, a number of powder delivery hoppers feeding a single manifold make nearly instantaneous color change a reality. This capability narrows the cost gap between reclaim and non-reclaim considerably as well. At the same time, powder manufacturing capabilities have evolved so that there may even be a wider selection of low-priced powder coatings that factor into the decision.

To Recycle or Not to Recycle

Determining whether to recycle or not recycle powder is really a numbers game—calculating labor and material costs as well as the cost of downtime. In a lean manufacturing operation, the downtime cost might be worth more than labor and material.

Setting the capital equipment budget aside, here are some common factors that might (and should) weigh in the decision:

1) How many color changes (per hour, shift, day) must be done?

2) How fast can color changes be made?

3) How much labor is available for color changing?

4) What is the labor cost?

5) How close to capacity is the line?

6) How much lost production (profit on goods) is lost during downtime?

7) How expensive is my powder?

8) How much ability to batch parts do I have?

9) What is my burdened line cost per hour?

Next you must match the answer to these questions to some of the potential solutions. Although there are many models and options to select from, powder systems tend to fall into a few broad categories of powder equipment.

High-volume color-change systems. These have been the traditional workhorses of high-volume production plants that run a few large-run colors and where it is possible to batch parts into longer production runs of a single color. These installations are great for reclaiming a high percentage of powder coatings, yielding high overall system efficiency of 98.5 percent. Frequently, these larger booths require 30–45 minutes for a typical color change. This group also includes multiple-booth roll-on, roll-off designs.

Faster color-change systems.

Over the past five years, a number of fast-color-changes systems have become popular. Color-change times have been reduced to the 5-10 minute range using cyclone technology, automated feed centers and new composite booth materials that are easier to clean. Self-cleaning booths have been developed where walls and floors are automatically blown free of over-sprayed powder. These cyclone systems are popular with plants where several color changes per shift are required. Reclaiming a high percentage of powder coatings yields high overall system efficiency of 95 percent.

Lean systems (color on demand). The most recent developments in powder are systems where it may not be possible or economically justifiable to reclaim powder coatings. If the labor cost is high and the powder cost low, and there are frequent changes, then spraying to waste may be the most sensible decision.

Developments such as dense-phase powder delivery have provided enough boost in first-pass transfer efficiency that the cost gap of reclaim and spray to waste has narrowed considerably. An added weapon in the color change arsenal is the recent capability to automatically change colors in 20 seconds or less in a lean cell. This super-fast-color-change capability allows guns and hoses to be rapidly purged for a second color.

Computer modeling tools can be used to test key parameters, such as lost production time. While plant supervisors and operators may focus on factors such as transfer efficiency, management may regard the largest impact of color change as lost production time. This is especially true of plants where the value of goods sold is very high and the plant is operating at high capacity utilization.

Maximizing Up Time

The value of lost production can rapidly tip the scale in favor of any approach that maximizes the productive “up time” of the paint line—quickly outpacing factors such as labor costs and powder savings.

The question might no longer be if quick-color-change powder coating is right for you, but which option is right for you. Today, all of the right tools are available to make good decisions. There are more technological options and tools to compare each option against any set of requirements. With so many powder coating choices, the possibilities with powder coating are tremendous as the technology continues to evolve.

Related Content

How to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreHow to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

Read MorePrevent Plating Problems with Critical Inspections

Tanks and their contents should be regularly inspected visually and analytically. When a quality issue arises, it is important to quickly pinpoint where the main problem is by checking which parameter is out of line.

Read MoreHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)