Q: Recently we started using electrostatic handguns in our painting process and the operators are complaining of getting painted. What can be done to avoid this and how do we know if the guns are working correctly? We are applying solvent-based coatings on steel pallet racking.

Electrostatic applicators have been used in a wide range of manual and automatic paint applications for many years. The primary benefit of using electrostatic is that it drastically increases the transfer efficiency. Stated otherwise, more of the coating sprayed goes on the part being coated due to electrostatic attraction.

The electrostatic process itself is relatively straightforward: a negative charge is applied to the coating material as it is being atomized. The electrically charged paint particles are attracted to the part being coated that is at ground potential (typically through attachment to the conveyor system). To troubleshoot your process, you need to evaluate the following three items:

- Equipment functionality (do you have voltage?)

- Grounding of the product being coated and the operator

- Compatibility of the coating material for electrostatic spray application

Equipment functionality

With an electrostatic spray gun, you need to ensure there is voltage at the tip of the applicator. Generally, electrostatic spray guns utilize a direct charge process which has an electrode in the fluid stream at the point where the fluid exits the applicator. This electrode directly charges the coating material and produces an ionized field in front of the applicator.

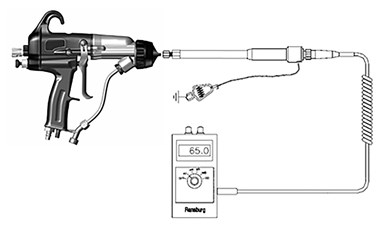

Prior to testing, ensure that the voltage is shut off and flush the applicator with the recommended cleaning solvent. Once the lines are flushed, use air to remove any residual solvent and ensure that the fluid lines are clean and dry. If you have a high voltage test meter/kit, follow the manufacturer’s instructions and test the applicator. This will consist of grounding the test meter, setting to the appropriate mode, and touching the probe to the electrode of the applicator while it is being triggered with voltage on (this may take two people). The meter should read within 10% of the applicator set point (if it is a 65Kv applicator, you should read around 59-65Kv).

High voltage test kit used to measure applicator tip voltage.

If you do not have a high voltage test kit, you can typically use the meters on the remote power supply or the indicator on the applicator. With the voltage enabled, pull the trigger on the applicator to activate the voltage function. If the indicator on the back of the applicator is bright green, your voltage is functioning properly. With the applicator still triggered on, take the electrode, and approach a grounded object (part to be coated or clean spray booth wall area). As the electrode nears ground (within 3 – 4"), the green light should start to dim. If you touch the electrode to ground, the light will turn red indicating that there is no voltage at the applicator. As you pull back from ground, the light should return to green.

If you have an electrostatic gun with a stand-alone power supply, you can monitor the voltage and current meter to test functionality. When the gun electrode is away from ground, the voltage should be high, and the current should be low. As the electrode gets closer to ground, the voltage should drop, and the current should increase. Once the electrode touches ground, voltage should be at zero and the current will be at maximum level. Once the electrode is pulled away from ground, voltage should increase back to operating level. The above tests may seem involved; however, they are very quick to complete and will quickly determine if the applicator in function properly forms a voltage perspective.

Grounding of product being coated and the operator

According to NFPA 33 (Nation Fire Protection Association) Chapter 12, the resistance between the object being sprayed and true earth ground must be 1.0 MΩ (Megaohm) or less. This provides suitable electrostatic attraction and permits the charge from the applicator to safely dissipate. This level of grounding applies to all objects in the spray booth, including the operator.

When using a manual electrostatic applicator, the operator is grounded through contact with the handle of the applicator which is conductive. The air hose, which is also conductive, is then used to complete the circuit to ground. It is important that the operator has skin contact with the handle or uses conductive gloves to ensure they are grounded.

Ground should be tested with a Megohm meter (often called a “megger”). A Megohm meter has an output of 500–1,000 volts, this is required to overcome contact resistances through the various attachment points. If a standard VOM (volt ohm meter) is used, inaccurate readings may be obtained. In most finishing systems, the workpiece is hung from a conveyor using load bars and hooks. It is important to ensure that the contact points are clean to ensure that good ground contact can be made through the various attachment points. The Megohm meter can also be used to check the ground integrity of the air house.

Compatibility of the coating material for electrostatic spray application

When using electrostatic application equipment, the resistivity of the coating material should be tested to ensure that it is within an acceptable range for the specific manufacturer’s equipment. Generally, for manual applications, the recommended range for resistance is between 0.1 MΩ (Megaohms) or higher. The primary concern is that the material is not so conductive (very low resistances) that the voltage applied at the applicator follows the fluid column to the grounded fluid supply. When and if this happens, the system current will increase, and the power supply will shut down most commonly with an “over current” fault.

If the voltage function tests ok with the applicator clean and dry but immediately faults out when materials are loaded, this is an indication that the material resistivity is too low.

Multifunction test kit can be used to test applicator tip voltage, part grounding and coating resistivity.

In summary, there are three primary elements related to the electrostatic process that are relatively easy to test to ensure proper operation: applicator tip voltage, part/operator grounding and coating material compatibility. Outside of that, spray technique and the air flow within the spray environment will also have some impact. Going back to your original question, since the operator is getting painted, we can assume that the electrostatics are working, the paint is compatible, and the operator is grounded. The most probable cause of your problem is poor part grounding. I recommend use of a Megohm meter to verify and ensure that all hooks and load bar contact points to the conveyor are clean.

About the Author

Payton Cozart

Payton is product manager for Carlisle Fluid Technologies. Visit carlisleft.com.

Related Content

Cobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

Read MoreRobots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

Read MoreIntumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreRead Next

Paint Booth Exhaust Filter Disposal

Steve Love, parts and filters sales manager, Global Finishing Solutions, discusses proper paint booth filter disposal.

Read MorePreventative Maintenance for Paint Line Conveyors

Dave Hesse, field installation superintendent, Global Finishing Solutions, offers suggestions for inspecting and maintaining your industrial conveyor system.

Read MoreControlling Temperature in Paint Process

Mike Bonner of Saint Clair Systems discusses using a temperature hierarchy to assess how to best control temperature in your paint process.

Read More

.jpg;maxWidth=300;quality=90)