March Finishing Business Index at 55

Numbers reflect the fastest growth since May 2012.

The Finishing Business Index, compiled by Gardner Research, a division of Products Finishing publisher Gardner Business Media, is emailed monthly to the magazine’s subscribers. This is a diffusion index, similar to the ISM index, where a reading of 50.0 indicates expansion and a reading below 50.0 indicates contraction in the industry. The total index is the average of six subindices—new orders, production, backlog, employment, exports and supplier deliveries. Other subindices are calculated to help determine the state of finishing shops. One average of this index relative to the ISM index is that the respondents are all finishers instead of small representative sample of all of U.S. manufacturing.

You can find all the finishing data at gardnerweb.com/forecast/finishing.htm.

With a reading of 55.0, Gardner’s March finishing business index showed that the finishing industry grew for the third consecutive month and at its fastest rate since May 2012. Since August, the level of business activity in the finishing industry has been improved dramatically. The March finishing index was 12.2 percent higher than it was in March 2013—the seventh straight month that it was higher than one year earlier. And the annual rate of change grew for the first time in at least four months.

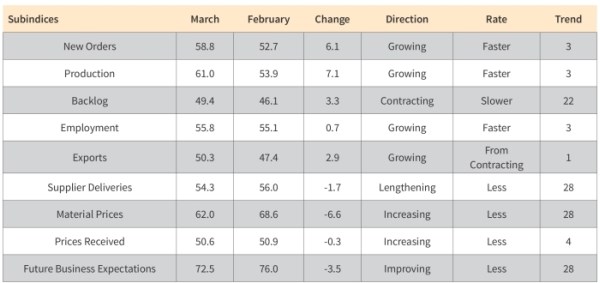

New orders and production both grew for the third month in a row; the rate of growth in new orders increased significantly, and the rate of growth in production was the fastest since May 2012. Backlogs are still contracting, but the rate of contraction in March was the slowest since May 2012. Backlogs have been improving since last September compared to year-ago levels, and, on an annual basis, they have increased at an accelerating rate in both February and March. This is a strong sign that capacity utilization and capital spending at finishing facilities will improve throughout the remainder of 2014. Employment increased in four of the previous five months, while exports increased for the first time since April 2012. Supplier deliveries continue to lengthen at a reasonably steady rate.

Material prices continued to increase in March, but the rate of increase fell off significantly from the previous month. Prices received by finishers increased for the fourth straight month, although in three of those months, the price increases were relatively minimal. Future business expectations were still noticeably higher than they were from the summer 2012 through fall 2013, but they did fall somewhat in March compared to the first two months of the year.

The business index improved substantially at finishing plants with more than 100 employees, rising to about 61.0 in March from 56.0 in February. At plants with 20-99 employees, the business remained relatively unchanged at 56.0, but finishers with 19 employees or fewer continued to contract. These facilities have not grown since August 2012.

Every region but one grew in March. The Middle Atlantic region grew at the fastest rate and has grown two of the first three months of the year. It was followed by the West South Central, East North Central, West North Central, South Atlantic and New England regions. The Pacific region was the only one to contract in March, although it contracted at a relatively minor rate after growing the previous two months.

After decreasing 23.2 percent in February, future capital spending plans increased 31.1 percent in March compared to one year earlier. This is the second-fastest rate of month-over-month growth in the history of the index, which dates back to December 2011. The annual rate of change in capital spending plans contracted at its slowest rate in five months.

Related Content

EPSI Acquires Custom Rack

EPSI is continuing to grow with the acquisition of Custom Rack, based in Euless, Texas.

Read MoreBeware the Employee Freeloader

Clearly communicate expectations, set goals, measure performance and trust your instincts.

Read MorePractical Environmental Management Reduces Costs, Refines Quality

By focusing on effluent treatment and efficient tin recovery, this Indian surface treatment plant meets stringent environmental standards and sustainable high-quality production.

Read MoreUmicore Metal Deposition Solutions Names Managing Director of Electroplating Business Line

Michael Herkommer has been named managing director of the electroplating business line at Umicore Metal Deposition Solutions.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.JPG;width=70;height=70;mode=crop)