Anguil Environmental Systems Seeks Pilot Customers for New IIoT Platform

Anguil’s IIoT platform is designed to leverage existing equipment data to improve performance, lower maintenance costs and prevent unplanned downtime through graphical overviews, KPI dashboards, live trending and document repositories.

Anguil Environmental Systems Inc. (Milwaukee, Wisconsin) has announced the launch of its Industrial Internet of Things (IIoT) software platform, and the company is now seeking participants for its IIoT pilot program.

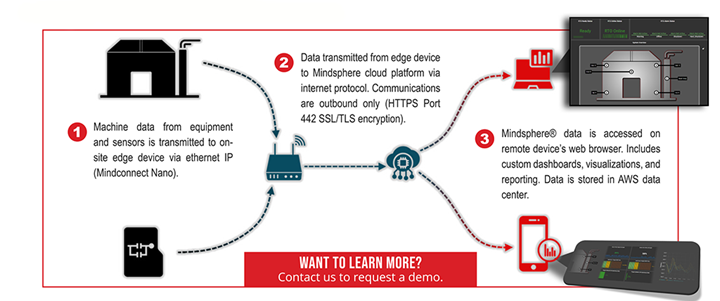

Anguil’s IIoT software platform is tailored specifically for enhancing operational transparency and reporting capabilities for environmental pollution control equipment. Anguil partnered with Siemens (Munich, Germany) to leverage its Mindsphere software, which provides data security and complex development components and tools. Anguil’s IIoT platform is designed to leverage existing equipment data to improve performance, lower maintenance costs and prevent unplanned downtime through graphical overviews, key performance indicator (KPI) dashboards, live trending and document repositories.

To further test and enhance its IIoT platform, Anguil is seeking industrial facilities with existing environmental technologies to participate in a pilot program. Participants partner with Anguil to integrate the IIoT platform with their environmental equipment for a six-month period, providing feedback on the existing interface and input on desired functionality. To qualify as a pilot participant, Anguil is seeking facilities willing to provide Anguil’s IIoT team technical access to their system control panel. Besides minimal set-up costs, there is said to be no cost to participate as a pilot customer and no long-term obligation. At the end of the pilot program, participants will reportedly be offered the option to continue IIoT services or to end the engagement with no pressure to purchase.

Related Content

-

NASF/AESF Foundation Research Project #121: Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing - 15th Quarterly Report

This NASF-AESF Foundation research project report covers the twelfth quarter of project work (October-December 2023) at Wayne State University in Detroit. In this period, our main effort focused on the development of a set of Digital Twins (DTs) using the Physics-Informed Neural Network (PINN) technology with application on parts rinsing simulation.

-

NASF/AESF Foundation Research Project #122: Electrochemical Approaches to Treatment of PFAS in Plating Wastewater - 10th Quarterly Report

The NASF-AESF Foundation Research Board selected a project addressing the problem of PFAS and related chemicals in plating wastewater streams. This report covers the 10th quarter of work (April-June 2023). Here, we examine the effect of surface fluorination of Ti4O7 anodes on PFAS degradation performance in terms of energy performance as well as formation of chlorate and perchlorate when chloride is present in the solution. The full paper on this work can be accessed and printed at short.pfonline.com/NASF24Feb2.

-

Explore Cleaning Chemistry, Metal Finishing Applications and Wastewater Treatment Solutions

Hubbard-Hall Celebrating 175 years of excellence, Hubbard-Hall presents chemistry and equipment.

.jpg;maxWidth=300;quality=90)