Helmee Opens US Facility in Georgia

The subsidiary expands CSD surface inspection solution sales and support to its North American customers.

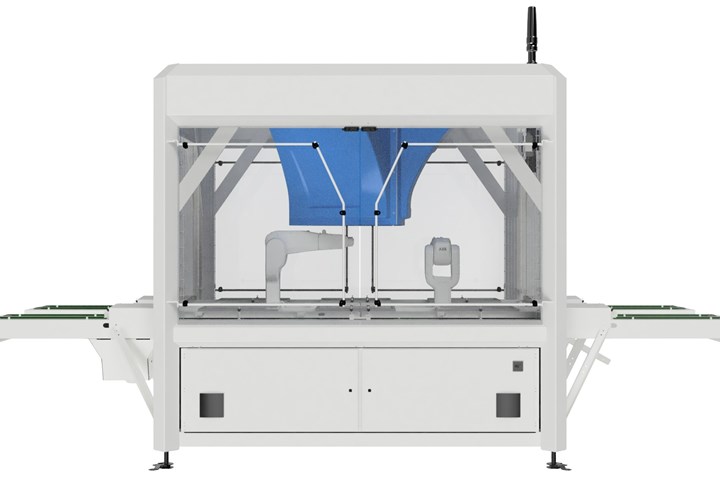

Helmee Imaging Oy, a developer and manufacturer of CSD imaging technology for challenging surface inspection applications, is opening Helmee Imaging Inc., a wholly owned U.S. subsidiary based in Cumming, Georgia. This subsidiary will provide sales with technical and application support for its customers throughout North America.

“The customers we work with have increasingly demanding needs for surface quality inspection where traditional methods, such as cameras or human visual inspection, do not work reliably or quickly enough,” says Juha Saily, regional development manager at Helmee Imaging Inc. “Our CSD technology offers higher resolution, more accurate inspection results and higher throughput than human visual inspection. It is the only in-process inspection technology that works on parts with complex geometries and mirror-like surfaces."

Covered stereo deflectometry (CSD) is a machine vision technology that enables automated quality inspection of flat, curved and complex parts with highly reflective and clear surfaces. CSD can detect virtually any type of microscopic and larger 2D and 3D defects, the company says. Applications include chrome-plated, painted and PVD-coated parts, as well as polished and uncoated products made of glass, metal and plastic. While CSD has uses in many different industries, Helmee’s primary focus is automotive parts, consumer electronics and medical devices.

Related Content

-

Titrations: To Automate or Not to Automate?

What considerations should you keep in mind for automatic titrations? Conor McAnespie of Hanna Instruments discusses the benefits of auto titrators.

-

BYK-Gardner Offers Protective Coatings Field Test Kit

New field kit includes tools for a proper assessment of environmental conditions prior to coating applications and film thickness evaluation.

-

Corrosion Resistance Testing for Powder Coating

Salt spray can be useful to help compare different pretreatment methods and coatings but it does not tell us much about the corrosion resistance of a part over time in the field. Powder coating expert Rodger Talbert offers insights into how to get a better idea of how to improve a part’s corrosion resistance in the real world.