Unique Rhodium Alternative for the Small Scale

Umicore Electroplating develops an electrolyte designed for smaller production

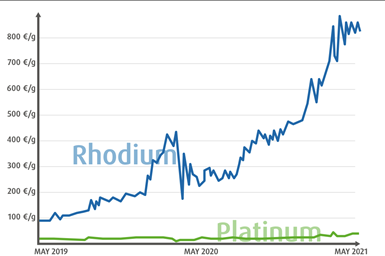

Rhodium costs about 40 times more than it did five years ago.

Photo Credit: Umicore Electroplating

Umicore Electroplating has responded to the price of rhodium rising by developing a more cost-effective alternative for small batch sizes. Rhoduna PT One is an electrolyte that is specially designed for rhodium plating on a small scale.

Due to the high price of rhodium, Umicore developed the rhodium-platinum electrolyte Rhoduna PT in 2018. The platinum price, which had remained constant over the years, puts the price increase of rhodium into perspective to a large extent. The resulting cost savings and only irrelevant qualitative compromises for decorative processes allowed the product to quickly become successful on the market. The almost identical coating properties with those of Rhoduna PT result from the closeness to the product.

“We quickly saw the need for an adaptation for small series. Over the last few months, the costs have gotten out of hand and switching to other precious metals is not an adequate substitute for certain requirements and applications. With Rhoduna PT One, we want to buffer the enormous increase in rhodium prices for small electroplating job shops, so that high-quality production can continue even on a small scale,” explains Markus Legeler, manager, international sales.

Umicore has made adjustments with regard to efficiency and in simplified handling. For example, apart from the electrolyte, only the simplest equipment is needed for the coating. The fact that the specified parameters (temperature, time, current, etc.) often cannot always be constantly fulfilled has also been taken into account. Thus, good coating results in a wider tolerance range are possible with simple means.

Umicore Electroplating | ep.umicore.com/

Related Content

-

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

-

Advantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.