Video Podcast: Norton | Saint-Gobain Abrasives' APS Automation Cell Tour

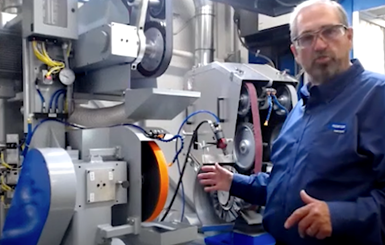

Mike Shappell of Norton | Saint-Gobain Abrasives, takes PF on a video tour of the company’s new Abrasive Process Solutions (APS) automation cell, which offers finishers a path to automation for mechanical finishing processes.

In this special video episode of On the Line, Products Finishing’s podcast for coaters and finishers, we learn about new solutions for robotic process development for mechanical finishing processes.

Mike Shappell offers a tour of the new Norton | Saint-Gobain Abrasive Process Solutions (APS) automation cell.

“Finding and retaining skilled personnel to perform many of the metal finishing processes in North America is a challenge. We often hear this from organizations that perform some type of surface finishing processes. From heavy grinding to deburring, to fine surface finishing, shops are being pressed for high quality and quantity output in order to keep up with demand. All this, while in many industries and many parts of the country, finding people that want to take on these physical and often dirty jobs, seems to be an unreachable goal. Where do shops go for help in trying to automate their processes or begin a proof of concept and be able to show justification for this move?” Mike Shappell, senior application enginer with Norton | Saint-Gobain Abrasives, stated in a 2021 article for PF.

In this OTL video, Shappell takes PF on a video tour of the company’s new Abrasive Process Solutions (APS) automation cell located in Northborough Massachusetts. The facility includes a robotic- based system designed specifically to assist finishers in performing various Proof of Concept activities that explore what’s possible through the use of abrasive products.

Related Content

-

AkzoNobel Uses VR for Training Airline Apprentices

The virtual reality technology provides a paint booth and spray gun that enables trainees to work and master their skills without losing parts in the process.

-

Top 5 Areas to Consider Automation of Plating Operations

Automation for finishing operations can lead to improvements in process time, repeatability and consistency of quality. Yet, processes that make sense to explore for these operational efficiencies may not always be readily apparent.

-

Unlock Unparallelled Reliability

By prioritizing reliability in every aspect of its service offerings Dynapower ensures your equipment operates at peak performance levels consistently. With a steadfast focus on reliability, Dynapower’s field service, preventative maintenance and spare parts solutions ensure uninterrupted operations, minimizing scrap and maximizing uptime.