Process Technology Expands XC Heat Exchanger Capability

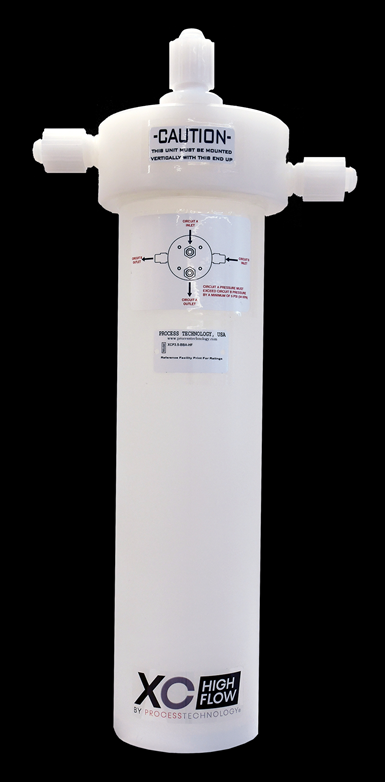

Process Technology’s new XC High-Flow Inline Heat Exchanger designed for precise and stable heat transfer while reducing fluid pressure drop.

XC High-Flow by Process Technology

The new XC High-Flow Inline Heat Exchanger from Process Technology delivers an ultra-high-purity (UHP), compact, high-flow heat exchanger with precise and stable heat transfer, while reducing fluid pressure drop. High-flow capacity is achieved with a larger 13 mm (0.5 inch) diameter tubing to improve circulation, reduce pressure drop and enable a faster temperature response. The low-mass unit is internally baffled for additional heat performance. Recirculating and single-pass flow applications provide safe heating for water, acids, bases and solvents. Clean-room assembled, no wetted o-ring, PFA tube-side chemistry paths allow the XC High-Flow to meet the most stringent cleanliness requirements to support next-generation ultra-high-purity semiconductor node technologies.

Process Technology | 800-621-1998 | processtechnology

Related Content

-

SUR/FIN 2023 Registration Is Now Open

The National Association for Surface Finishing SUR/FIN 2023 surface finishing industry trade show will take place June 6-8, 2023 in Cleveland, Ohio.

-

Plasma Electrolytic Oxidation (PEO): A High-Performance Coating for Light Metal Alloys

Plasma Electrolytic Oxidation (PEO) offers an innovative approach to high-performance coatings for light metal alloys, providing superior alternatives to traditional hard anodizing. The process transforms the surface of metals like Al, Mg and Ti into a robust oxide layer with customizable properties, tailored for demanding applications in aerospace, semiconductor, and industrial manufacturing.

-

Calculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

.jpg;maxWidth=300;quality=90)