Asterion Introduces New Zinc-Nickel Process

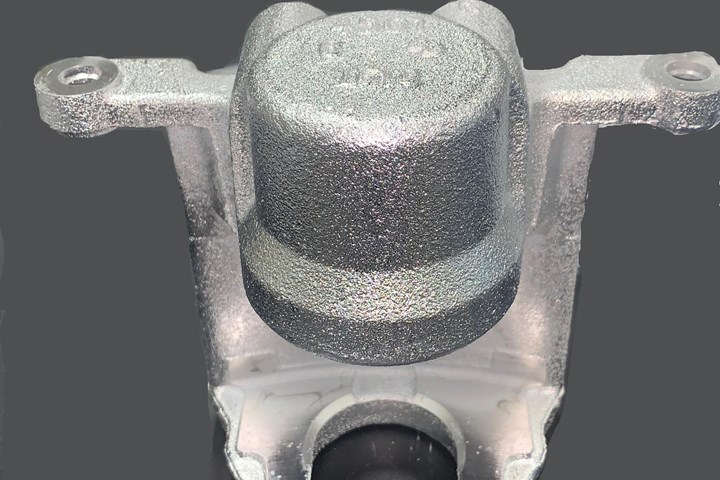

Asterion’s TECHNILLOY ZN NI 770 process offers corrosion protection, while delivering consistent and repeatable uniform surfaces.

Source | Asterion

Asterion LLC (Indianapolis, Ind.) has introduced an acid, zinc-nickel process known as TECHNILLOY ZN NI 770. Approved and specified by leading automotive and heavy equipment manufacturers, the new process offers corrosion protection, while delivering consistent and repeatable uniform surfaces.

TECHNILLOY ZN NI 770 is formulated to plate heat-treated, difficult-to-plate fasteners and other complex part geometries. The process boasts uniform zinc-nickel distribution with high current density efficiency and good throwing power and coverage. The non-ammoniated process is compatible with clear, black, and yellow trivalent passivates, and plates on steel, cast iron and sintered metal. It offers an aesthetically pleasing bright finish and is suited for both rack and barrel operations.

Asterion LLC | 800-428-0719 | asterionstc.com

Related Content

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

-

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

.jpg;maxWidth=300;quality=90)