Brighton Science Unveils Cloud-based Surface Intelligence Platform

Next-generation solution uses data and analytics to prevent bonding and adhesion issues.

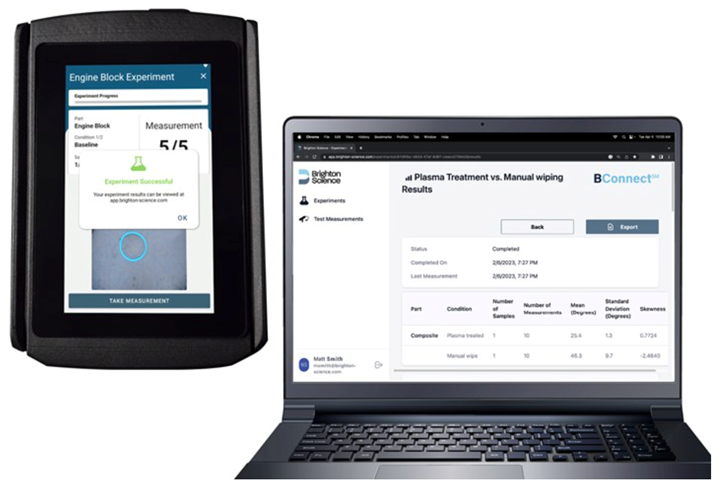

Brighton Science (Cincinnati, Ohio) has introduced a surface intelligence subscription service that includes networked instruments and a cloud-based data-sharing platform. Known as BConnect, the solution runs on Brighton's proprietary SaaS platform, collects data from networked devices that assess surface readiness for bonding, coating or sealing by measuring the water contact angle. Because 90% of surface failures are due to a lack of surface readiness, getting this datapoint is critical throughout the development and production process.

Unlike tools that are centered on scientists and limited to the lab, BConnect gathers and distributes vital data to teams throughout the enterprise and around the world. This enables engineers, product designers, vendors, line operators, executive leadership and others to communicate with greater ease, speed and efficiency — bridging expertise gaps and language differences.

Brighton CEO Andy Reeher explains, “Nearly every product that’s made today has some kind of surface bonding requirements, whether that’s paint, glue, coatings or adhesives. For decades, companies have struggled to understand why certain materials fail, because what’s happening on these surfaces is invisible.” He continues, “Getting real-time surface readiness data and sharing it is a frontier where none have ventured before, and the implications are game-changing. If we can help our customers see what’s happening molecularly on those surface interfaces, they can get more predictability and assurance with their bonds, which will unleash innovation with new materials and make their existing products more durable and sustainable."

Brighton Chief Science Officer Giles Dillingham, Ph.D., adds, “The rate of innovation in manufacturing is exponential right now, with revolutionary new materials. Yet unseen environmental conditions and simple human choices continue to compromise surface integrity. Our BConnect system can now accomplish what traditional QA cannot—bringing more visibility and certainty to the manufacturing process.”

BConnect is a subscription-based offering that includes highly sensitive mobile and inline sensors that collect surface readiness data and wirelessly upload it to the BConnect cloud-based SaaS platform. Completely customized for each company and its users, these Surface Intelligence networks are said to give teams a common language and data set to innovate, troubleshoot and optimize processes while reducing costly waste and recalls. All data collected via BConnect is private and proprietary to each company.

Companies that subscribe to BConnect can also opt in to the SIQ Community, an emerging industry collective committed to advancing knowledge and driving innovation in the surface science space — collaborating on topics like increasing sustainability, speed and safety in global manufacturing.

Related Content

-

BYK-Gardner Offers Protective Coatings Field Test Kit

New field kit includes tools for a proper assessment of environmental conditions prior to coating applications and film thickness evaluation.

-

Online Energy Savings Calculator Promotes Energy Efficiency

An online energy savings calculator from AkzoNobel aims to help customers determine how to reduce energy usage.

-

Attention to Measurement

English vs. Metric — which should you use? Ron Kinne of Haviland Enterprises Inc. explains why you need a firm understanding of both for measuring various aspects of plating processes.