Graphene-Enhanced, Water-Based Architectural Paint

According to Gerdau Graphene, the new paint is ideal for use on concrete, cement, metal and asphalt.

Gerdau Graphene (São Paulo, Brazil), a nanotechnology company pioneering advanced graphene-enhanced materials for industrial applications, announces the creation of a new water-based architectural paint that is said to be significantly more durable and resistant to abrasion than traditional paints.

According to the company, the new paint is ideal for use on concrete, cement, metal and asphalt. Its parent company, Gerdau, began applying the new paint to its factory floors in March, reportedly making it the world’s first large-scale use of a water-based graphene-enhanced architectural paint. The company is already selling its proprietary graphene additives as development prototypes to major paint producers in the Americas. The announcement follows recent news that the company has developed new graphene-enhanced thermoplastics.

The development of the graphene-based paint started in December 2021 and is the result of a partnership with Grafftex (Londrina, Brazil) and Polystell (São Paulo, Brazil). Gerdau Graphene created the graphene technology used to disperse graphene into a paint additive.

Gerdau Graphene is also working on additives for anti-corrosion paints, focusing on reducing heavy metals and fossil-based ingredients from light and heavy maintenance paints. The company plans to pilot the coating in its own operations and then launch the new products commercially in early 2023.

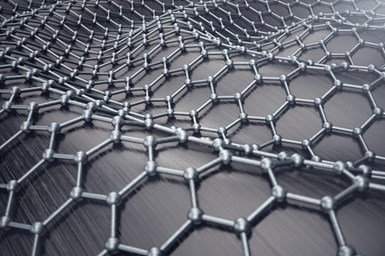

Graphene is a one-to-ten atom-thick sheet of densely-compacted carbon that can be modified for various uses and added to industrial materials. Graphene can be used to produce durable coatings that do not crack, are resistant to water, oil, and other liquids and have antimicrobial, anticorrosive and anti-UV properties.

Related Content

-

Architectural Powder Coating Mimics Natural Stone

AkzoNobel offers new stone effect powder coating for North American market.

-

Longlasting Nanotechnology Coatings Provide Barrier to Chemicals, Corrosion

The company moved its global headquarters from Houston in 2022.

-

Epoxy Rebar Company Reinforcing Roads of the Future

Providing epoxy-coated rebar with the ultimate corrosion resistance is Simcote’s focus for the infrastructure industry it serves.

.jpg;maxWidth=300;quality=90)