Hydrogel Coating Prevents Ice Formation

Coating was inspired by a natural mechanism that keeps blood from freezing in several species of fish that live near Antarctica.

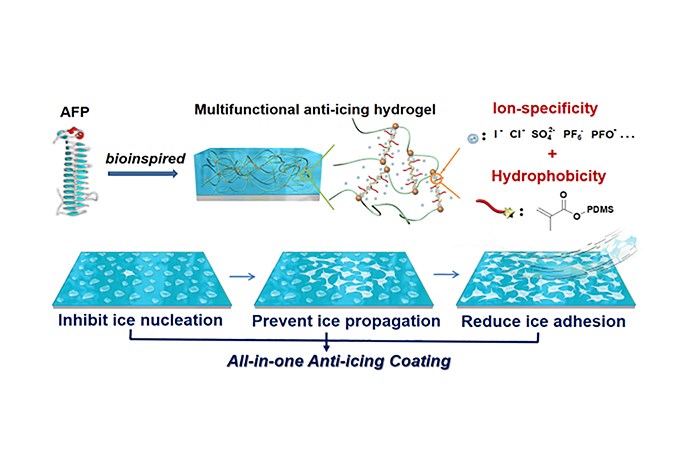

Materials scientists at the UCLA Samueli School of Engineering and colleagues in China have developed a coating that prevents ice from forming, inspired by a natural mechanism that keeps blood from freezing in several species of fish that live near Antarctica.

The researcher’s study, which is published in Matter, suggests that the new coating could be an inexpensive and versatile solution for preventing critical parts on airplane wings, outdoor pipes and other equipment from freezing over in cold temperatures. It is the first material that prevents ice formation by acting on three distinct aspects of ice formation.

“Ice formation starts from nucleation, when a small seed crystal of ice first forms, before it grows and then finally adheres to a surface,” says Ximin He, who led the study and is a UCLA assistant professor of materials science and engineering. “While there are anti-ice solutions out there, they’re designed to tackle only one of these three aspects of this complex process or they only work on certain types of surfaces. This new coating is an all-in-one solution to prevent ice formation on many different surfaces, from plastics to metals to ceramics, and under different conditions.”

He said the material is also simple to make and very durable. The gel is made mostly of water, but its key ingredient is polydimethylsiloxane, a nontoxic, silicone-based polymer used in contact lenses, cosmetics, lubricants and other applications that require some slipperiness.

When sprayed onto a surface, it forms a thin, transparent coat that helps prevent freezing in three different ways: lowering the freezing temperature of water on the surface, delaying ice crystals from growing and making it difficult for ice to stick to the surface.

The researchers tested the coating on several materials, including plastic, glass, ceramics and metals. It set a record by preventing ice from forming until the temperature reached -31oC (-23.8oF). The previous record of -28oC (-18.4oF) was established in 2016 when a different coating was applied to silicon and glass. The research group that conducted that study was led by Jianjun Wang of the Chinese Academy of Sciences in Beijing, who also was a co-author of the latest research.

Water usually freezes around 0oC (32oF), although the precise freezing point depends on environmental conditions. The hydrogel also set a record for the amount of time it delayed ice from forming at a temperature of -25oC (-13oF). In the study, materials including plastic, glass, ceramics and metals that were coated with the hydrogel took more than 65 minutes for ice to form at that temperature, more than 40 minutes longer than the previous record, which also was set during the 2016 study.

And, even if ice does form on an object’s surface, the hydrogel coating makes it easy to remove the ice by simply brushing or blowing it off, without scraping the object or applying heat.

In the 1960s, scientists discovered that several species of Antarctic fish make proteins that work as an antifreeze for their bloodstreams. Similar proteins have since been found in insects, microorganisms and plants. The new coating works, in part, through mimicking the molecular structure of those proteins.

The researchers conducted much of the experiment in a laboratory, although one test was performed outdoors in Beijing at below freezing temperatures.

Other UCLA authors of the study were Zhiyuan He, Mutian Hua, Shuwang Wu and Dong Wu, all members of He’s research group. The other authors were Chenyang Wu, of the Chinese Academy of Sciences in Beijing, and Xinyuan Zhu, of Shanghai Jiao Tong University.

He is an expert on hydrogels. Wang’s lab at the Chinese Academy of Sciences studies anti-icing.

The study was supported by the National Science Foundation, the Air Force Office of Scientific Research, the Hellman Fellows Fund and the National Natural Science Foundation of China.

Information provided by Matthew Chin, UCLA

Related Content

Henry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreTTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)