Henry Ford and the Model T. The man found the color black to be efficient for process simplification. More than 100 years later, people find black and other achromatic colors appealing.

Photo Credit: Ford Motor Co.

Henry Ford’s statement, “Any customer can have a car painted any color that he wants so long as it is black,” was made at a sales meeting. In his My Life and Work (1922), he followed up with an observation, “I cannot say that anyone agreed with me.”

According to research conducted by Trent E. Boggess, an economics professor at Plymouth State University:

- “[T]he paints used on Model Ts during the black era years of 1914 to 1925 were really color varnishes. These types of paint bear little resemblance to the modern automotive finishes used today when restoring a Model T.”

- “[O]ver 30 different types of black paint were used at the same time to paint Model Ts. The different types of paint vary according to the means of drying them (air versus oven drying) and were also formulated to satisfy the different means of applying the paint to the different parts.”

- [T]he color black was chosen because it was cheap and it was durable. Black paints, especially those containing asphaltum, were noted for exhibiting better damp-proofing properties than other colors during this period. The claim that black was chosen because it dried faster than any other color is not supported by the Ford engineering documents, the contemporary literature, nor by the first-hand accounts of Ford Motor Company employees.”

So it wasn’t paint as we know it; there were plenty of different blacks, and the drying properties — often cited as why Henry Ford made the quote — apparently weren’t germane to the selection.

It is also worth knowing that Ford was a big proponent of singular focus in terms of product, as well.

Realize that prior to the Model T the company produced the Model A (1903-1904), Model B (1904-1905), Model AC (1904), Model C (1904-1905), Model F (1905-1906), Model K (1906-1908), Model N (1906-1908), Model R (1907-1908), and the Model S (1907-1908).

It should be noted that these vehicles — and early versions of the Model T, which was introduced in 1908 — were available in colors including green, blue, gray and red.

After the Model S, it was only the Model T. The vehicle that replaced it, named the Model A, wasn’t introduced until 1927.

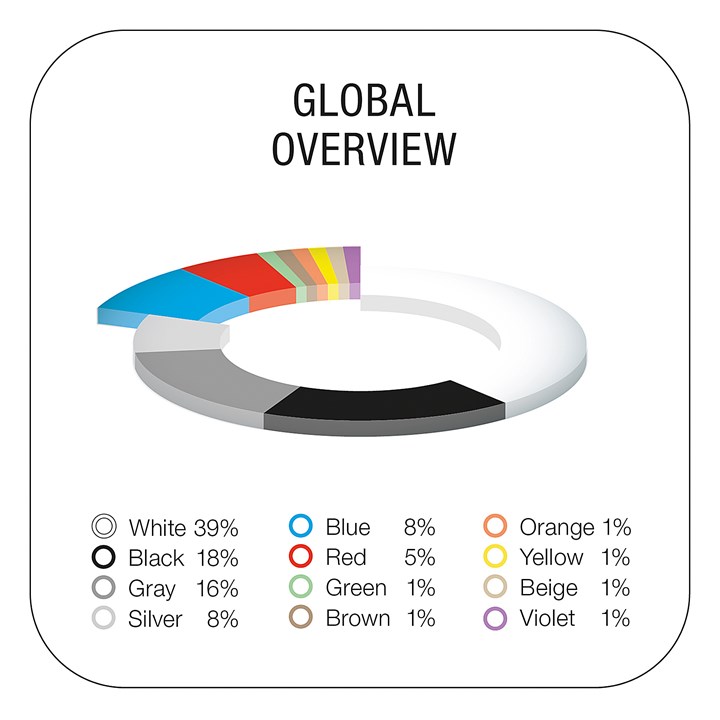

In its global survey of automotive colors, BASF found that achromatic colors — white, black, gray and silver — are the dominant choices on a global level. White and black alone constitute 57%. In the North American market, the findings are similar although white (33%) and black (22%) still account for more than half.

Photo Credit: BASF

Achromatic Colors Matter

Still, when it comes to achromatic colors, like black, Henry was right, even today, more than 100 years later.

But when it comes to global and North American demand, he was off a bit because the most popular color for non-commercial vehicles is actually another achromatic, white, according to the BASF Color Report for Automotive OEM Coatings (https://www.basf.com/us/en.html).

On a global basis, white has 39% of the market, up 2% from 2021.

Black is in second place at 18%, a 1% increase year-over-year.

Gray is in third at 16%, another 1% increase.

All three achromatic colors.

Then there is a drop to 8%, with another achromatic color, silver, and a chromatic color, blue, also at 8%.

Red is at 5%, then green, brown, orange, yellow, beige, and violet are all at 1%.

And North American Colors Aren’t Much Different

The North American numbers BASF calculated are somewhat similar, although the top three colors are tighter in terms of their take rate:

- 33% white

- 22% black

- 15% gray

And the next color is not silver as it is globally, but blue, a chromatic color. Blue is at 10%, then silver at 8%.

The remaining color choices for non-commercial vehicles in North America in 2022: red at 7%, green at 2%, and violet, beige and yellow all at 1%.

Looked at another way, the combined chromatic colors equal … black. 22%.

Why These Colors?

One might imagine that more than 100 years after the mono-color black was dominant on vehicles, consumers would be interested in having vehicles that weren’t white or black.

So we asked Liz Hoffmann, Lead Color Designer for the Americas, BASF, what her assessment is.

Hoffmann replies, “White and black are the most popular for several reasons. White is a color space that’s associated with safety, while black is associated with stature, especially on premium and performance vehicles. Both have timeless beauty and high resale values.”

More pragmatically, perhaps, “Large fleets also tend to favor white or black, usually with an eye toward resale.”

Feeling and Appearance

Hoffmann adds, “And finally, individual buyers choose white or black as an extension of their personality. Many report white car drivers as peaceful perfectionists, and the color is cooler in feeling. People who choose black cars have that feeling of stealth and power, and the color is cooler in appearance.”

Related Content

The Value of Robotic Paint Performance Testing

Considerations for implementing the use of automation for paint performance testing.

Read MoreIntumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

Read MoreRobots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

Read MoreTTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)