Rex-Cut's Grinding Wheels Designed for Pipe Welding

Velocity pipeliner and the grinding wheel designed for rugged applications.

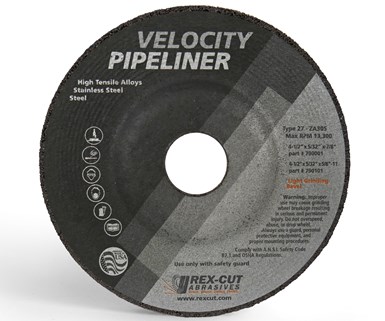

Rex-Cut Abrasives’ line of alumina zirconia grinding wheels for pipe welding applications includes the velocity pipeliner and the velocity grinding wheel.

Velocity pipeliner

According to the company, the pipeliner is a rugged wheel designed to withstand the pressures of pipe beveling, smoothing flame cut edges and root pass grinding in the oil and gas pipeline industry. It is said the premium grain and hard bond blend give velocity long life and excellent wheel performance on stainless steel and high tensile alloys. The pipeliner is available in alumina zirconia 30 grit in 4-1/2” × 5/32” × 7/8” and 4-1/2” × 5/32” × 5/8-11.

The velocity grinding wheel has a ¼”=thick version which the company says works for general fabrication applications such as heavy weld grinding, beveling hard steels, grinding casting parting lines or removing weld deposits.It is said the grinding wheel has a maximum stock removal rate balanced with extended wheel life on stainless steel and ferrous metals such as structural steel and iron. The grinding wheel is available in alumina zirconia 24 grit in 4-1/2” × 1/4” × 7/8” and 4-1/2” × 1/4” × 5/8-11.

Visit Rex-Cut Abrasives.

Related Content

-

Lapping, Polishing Film Maximizes Strengths, Maintains Flexibility

Dia-Strip and Dia-Sheet film from Titan Tool Supply has a distinct construction that the company says makes it durable while remaining flexible, bendable and formable.

-

Having a Blast: Best Practices for Media Blasting

5 considerations for media blasting as surface preparation for coatings.

-

Calculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.