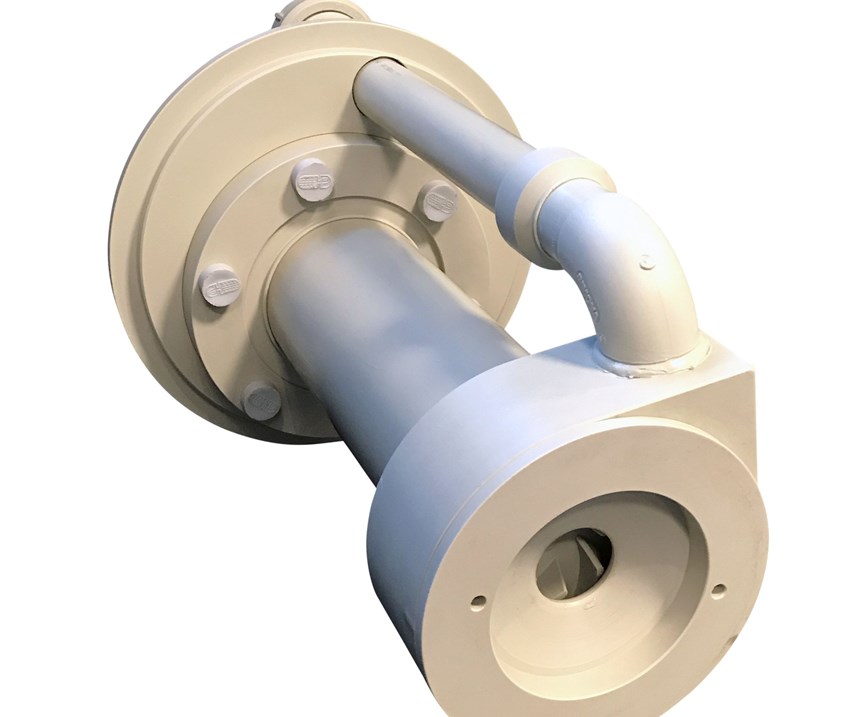

Sealless Vertical Pump Offers Increased Efficiency

Hendor is introducing the D13 series vertical pump, which features a hydrodynamic design that enables 33 percent more flow with a 33 percent smaller motor and replaces its D110 series as a one-on-one drop-in replacement.

Hendor is introducing the D13 series vertical pump, which replaces its D110 series as a one-on-one drop-in replacement. The new pump’s hydrodynamic design enables 33 percent more flow with a 33 percent smaller motor, the company says, resulting in power savings of 42 percent.

According to Hendor, the new pump was chosen over competitors by a renowned German reel-to-reel plating company because of its solid construction, high flow rate versus small motor size and potential for power savings.Related Content

-

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.