If the finishing industry wants to predict the future of the parts cleaning market, it needs to look across the pond at European trends and new developments taking place there. After all, Europe has long accepted parts cleaning as a necessary process, not a necessary evil, as the U.S. often considers it. As cleaning regulations continue to evolve and become more stringent, it’s the European Union that sets the pace for these requirements. The U.S. follows.

The 15th edition of the parts2clean show in Stuttgart, Germany, held in October, confirmed that Europe leads the way in parts cleaning technology. The trade show featured 253 exhibitors in the industrial parts and surface cleaning industry from 16 nations. The largest parts2clean yet, it attracted 4,900 visitors from 41 countries—almost 20 percent more visitors than in 2015.

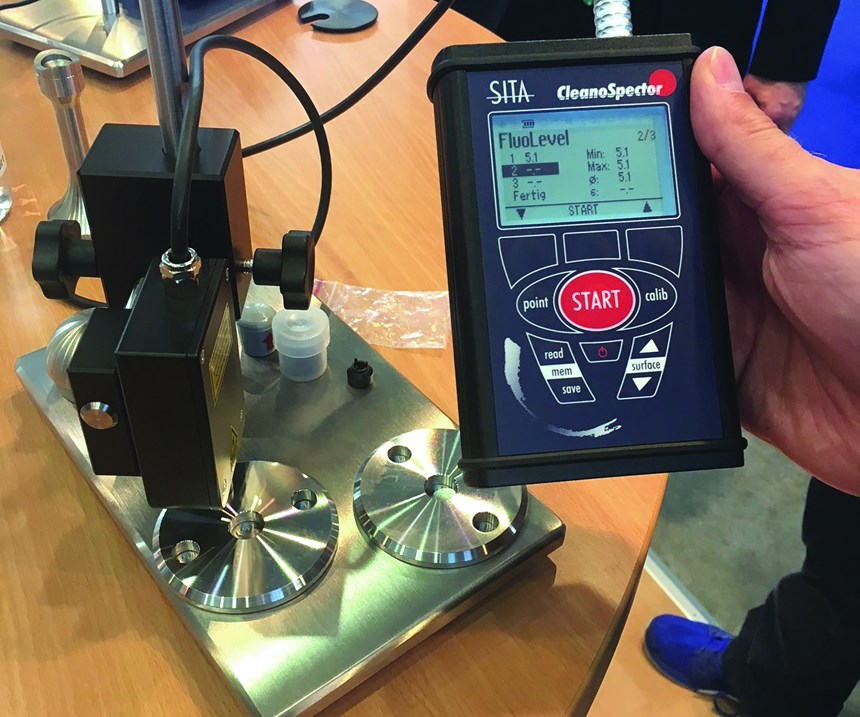

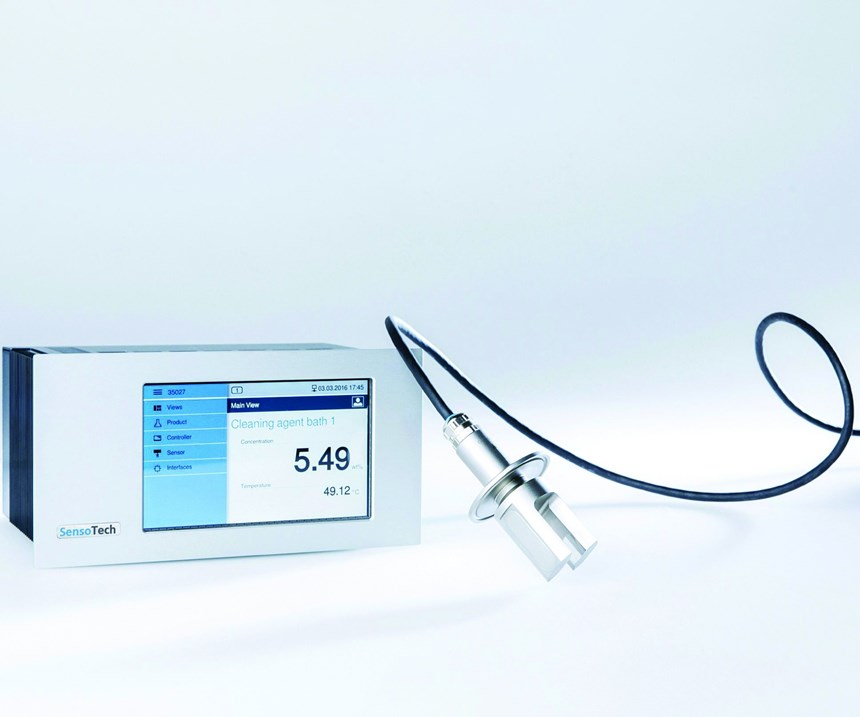

Not only were there solutions for cleaning, degreasing, demagnetizing, bath care, corrosion protection, and handling and packaging of cleaned workpieces, but cleanliness control, and analysis and monitoring equipment also were showcased in a big way. In fact, many of the displays on the show floor reflected this trend toward more quality control. Sensors, monitors and cleaning analysis equipment were prevalent throughout, and popular among attendees.

As far as cleaning regulations go, the buzz at the show was that even more stringent requirements are on tap, including for U.S. companies. This supports the expectation that the U.S. parts cleaning market will gradually grow because increased regulations will spur increased demand for this type of equipment.

So the cleaning industry is growing, and it’s important for U.S. machine shops to understand and embrace what’s soon to be required for cleaning the parts they produce. To help with this, the metalworking industry offers additional opportunities for shops to learn more about parts cleaning technologies and regulations. The International Manufacturing Technology Show (IMTS) this September will feature exhibitors in the parts cleaning segment, and next year’s Parts Cleaning Expo (PCx) will give attendees even more exposure to the cleaning technologies available to the U.S. market.

The images presented here include several products featured at last year’s parts2clean show.

Related Content

-

TTX Environmental Solves Customer Issue with Electro-Ceramic Desalination Wastewater Processing

Electroplating facility without access to a drainage system found a safe solution for wastewater treatment and reuse.

-

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

-

Clean Technology Lasers for Coating Adhesion

Laser cleaning systems remove corrosion, grease, residue and existing coatings from metal surfaces quickly, with less preparation and mess than traditional techniques.