Surface finishing shops have much to gain from implementing automation technology into their production lines. Robots can enable finishers to take the people out of unsafe or undesirable roles, meaning operators working the applicators can step out paint booth, remove the hazmat suits and bring value elsewhere in the finishing process. Additionally, robots can be a solution to the ongoing skilled labor shortages. But with each positive impact, some drawbacks keep finishers from going all-in on a robotics system.

First and foremost, implementing robotics can be an expensive, time-consuming process. Once the lines are set up, parts loading and racking must be exact each time for the robot to correctly apply the coating to a series of parts. Further, traditional automation systems struggle to adapt to high-mix, low-volume part mixes that are common in finishing because each part type has its own unique programming concerns.

To provide a solution to these drawbacks, robotics software startup Omnirobotic is delivering an automation solution that could provide shops that were previously on the fence about bringing robots into their finishing lines with a reason to dive in.

A software platform for autonomous robotic systems

Founded in 2016, Omnirobotic is a Laval, Quebec, Canada-based technology company that works to lower the barriers of entry for finishing shops to adopt automation, as well as improve the process for shops that have already done so. Omnirobotic does not manufacture robots, but it does provide them with an improved brain and operating system to automate the way they think, and the company’s products are specifically designed with finishing processes and applications in mind.

Omnirobotic’s system can hand a range of parts mixes, and it can adapt to new parts as they come down the line in real time.

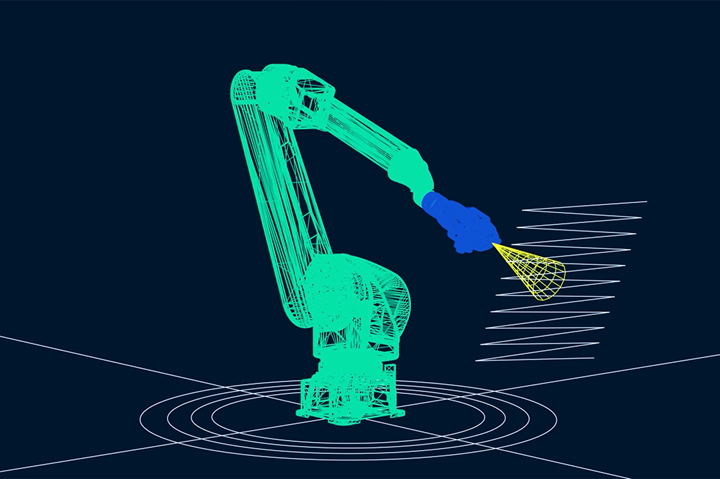

Robert Ravensbergen, Omnirobotic’s marketing director, says the company’s technology leads to an “autonomous robot that can function without explicit guidance or control.” Compared with traditional automation and robotics systems, which require labor-intensive programming and constant monitoring, Omnirobotic’s system provides a more streamlined way to reach an efficient robotics system. Ravensbergen says, “When it comes to our technology, it’s a different paradigm. It’s designed to adapt to the shape of the part in real-time for an undefined number of parts. It could be one part over and over, or it could be a million different parts over the course of several years.”

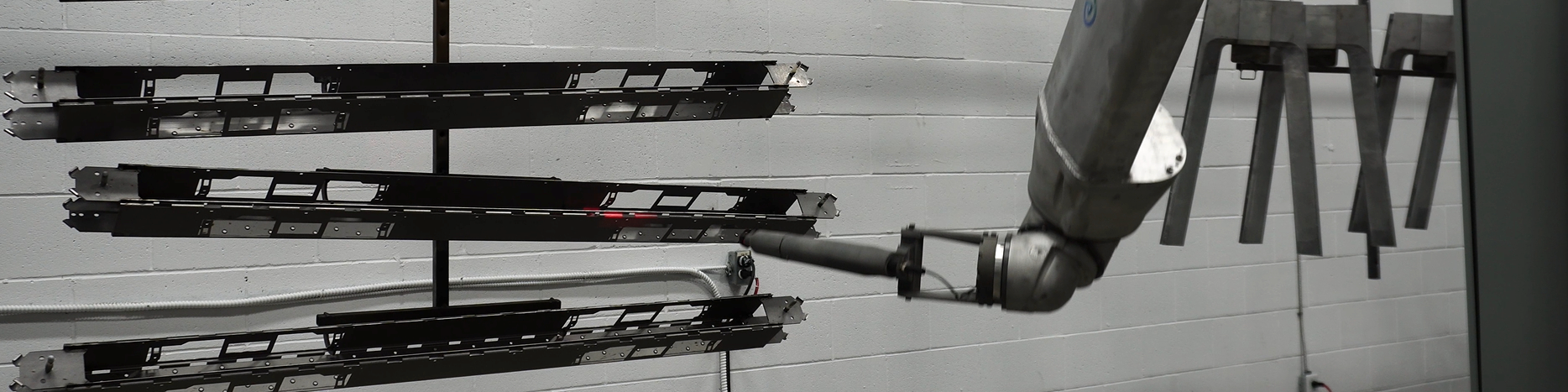

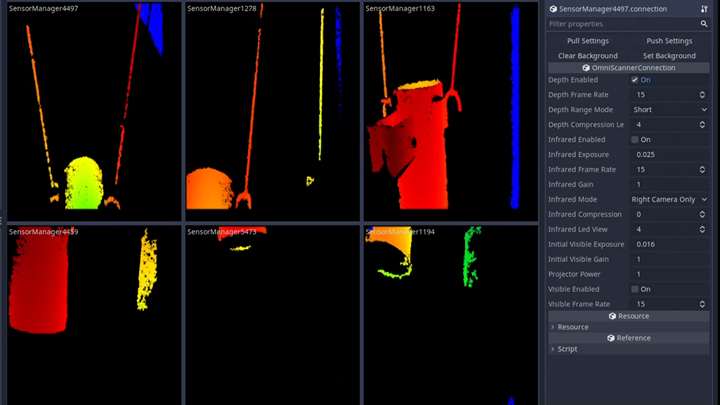

Omnirobotic’s system supports batch and overhead conveyor workflows, and it is compatible with robots from FANUC, ABB and more. The process is powered by AutonomyOS, a robotics operating system that enables the robot to read the parts in front of it using 3D perception; it leverages infrared and sensor fusion via a 3D vision system to generate a shape of the part as it passes through the line upstream of the paint or powder cell. The image is then sent to the hardware that operates AutonomyOS-powered systems, the OmniBrain. The OmniBrain uses a digital twin of the shop environment that enables the robot to recognize walls, collisional objects, robot constraints and anything else that might impact the process.

The OmniBrain uses algorithms within AutonomyOS to generate robot motions for each part that comes down the line, and the system is able to read and adjust to differences in how parts are racked. Workers can rack a series of parts however they want in any order and the robot will be able to detect differences and account for each unique part, which is an advantage this system has over traditional robotics. For many surface finishing operations, “those incremental costs of programming and jigging just make robotics out of the question,” Ravensbergen explains.

Omnirobotic’s AutonomyOS system also allows for customization of specific behaviors, such as differences in coating thickness. “What we’re providing is something that essentially is a platform that enables people to build according to their layout, their workflow, their spray process and their cell so that they can get the consistency they want,” he adds.

The system is designed to help shops avoid having frequent consultations with their robotics system integrators or hiring designated robotics programmers. Instead, the robot can learn and adapt to do those tasks for them. “For the amount of time it takes to program a robust robotic system with an integrator, you could be looking anywhere from 20 to 100 hours per program,” Ravensbergen says. “Whereas if you want to generate robot program in real time — in a matter of seconds, more or less — you can do that with our technology.”

A solution for high-mix, low volume

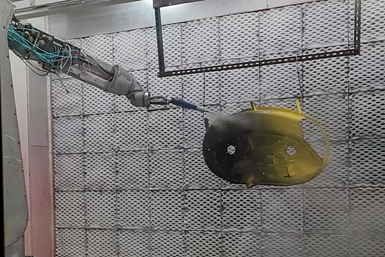

Current finishing applications for Omnirobotic’s system include powder coating, batch painting and sanding, and shops with high-mix, low-volume jobs perhaps have the most to gain. If a powder coater has a rework job that only consists of two or three rejected parts that need to be recoated, a line with Omnirobotic’s technology in place would automatically program itself and execute the job in minutes. “We’re taking the human out of the loop on that process,” Ravensbergen says. “They define behaviors, instructions or some specifics on the front end, but then they can get up and walk away, and the system will still run.”

“The potential for multi-purpose autonomous robotics technology is transformational, especially for high-mix manufacturers,” says Barton Faylor, FANUC’s program manager, general industrial paint. He adds, “By helping robotics providers like FANUC offer a new set of solutions, high-mix manufacturers can now take advantage of the savings associated with automation and continue their flexibility on rack density and new part introduction.”

Continuous powder coating and batch liquid spraying processes are two key capabilities of Omnirobotic’s technology.

Specific industries that could see benefit include furniture, heavy equipment, office supplies, lawn equipment or any industry or application that sees a high mix of parts. “That level of variation has been impossible for robotics, unless you have like 10,000 or 50,000 units of one particular part,” Ravensbergen says, “and then that’s something you can use a robot for. But then anything below that is not worth it.” Omnirobotic’s system, in comparison, enables finishers to tailor their systems for the specific job at hand, no matter how large or small.

Therein lies the transformative potential of Omnirobotic’s system for the surface finishing industry, a sector that has rarely been able to tap into the potential of robotics. Faylor adds, “With autonomous systems in the field, this untapped market will finally see all the benefits of robotics that mass manufacturers have seen all along.”

Related Content

Finishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreChecon Expands Market Offering with Acquisition of Umicore Electrical Materials USA, Inc.

The company is strategically working to meet future growth opportunities surrounding the use of precious metals and conductive materials like copper and aluminum.

Read MoreRead Next

Omnirobotics' Shape-to-Motion Tech Supports Wide Variety of Spray Processes

Omnirobotics' Shape-to-Motion Technology Supports Wide Variety of Spray Processes

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More