(Left to right) Pioneer Metal Finishing Green Bay general manager Chad Winka, CEO Steve Smith, director of engineering Dave Whedon, and market development director Chris Haasch.

Photo Credit: All photos by Products Finishing

Pioneer Metal Finishing is a bit of a heavyweight within the world of surface finishing. Founded in 1945, the company operates 11 facilities across the United States and Mexico and boasts more than 1,000 employees. Pioneer’s headquarters is based in Green Bay, Wisconsin — a location that marked the beginning of the company’s growth when it moved there from its original Minneapolis location and became a multiple facility operation. The company headquarters and flagship shop in Green Bay has qualified as a Products Finishing Top Shop every year since the inception of the Top Shops Benchmarking Program, but the scope of what Pioneer does requires looking at the company as a whole.

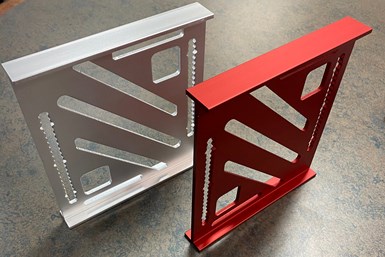

An example of anodizing at Pioneer’s Green Bay facility.

According to Chris Haasch, market development director for Pioneer, the company’s core offering across facilities is anodizing (Type I Anodize, Type II Hardcoat, Type III with PTFE and Vortex Anodizing), but from there, the focus of each of Pioneer’s facilities depends on the geography and customer base within each location. For example, the company’s newest acquisition in Mexico is a coating operation focused primarily on underbody applications for the automotive industry, such as rubber to metal adhesive coating. Pioneer’s Salt Lake City facility offers a host of painting and powder coating capabilities. Haasch says the company’s growth has been through a mix of acquisitions, organic growth and greenfield startups, such as its Monroe, Michigan, location.

With a mix of capabilities strategically based to serve various markets, Pioneer intently has its eye on the trends in manufacturing. CEO Steve Smith explains, “We’ve got four key verticals: medical, aerospace and defense (and within that we include electronics), and then, of course, we’ve got general industrial and automotive. What we’ve done — and continue to do a better job of — is tuning into the market indicators out there, and working to anticipate what some of those moves might be.”

General manager Chad Winka demonstrates automated racking capabilities at the Green Bay facility.

Engineered solutions

In February of 2022, Pioneer Green Bay treated Products Finishing to a tour of their award-winning facility. While “metal finishing” may be part of the company’s name, the term we heard most during our visit was “surface engineering.”

Haasch points out that at the core of Pioneer’s business model lies a focus on problem solving and innovation. While many coaters function as an applicator — taking an approved product and applying it to meet a defined spec — Pioneer works to find unique solutions to meet its customer’s needs.

“[Pioneer] specializes in surface coatings that have the ability to be engineered,” he says. “We’ve done that by working closely with our customers to get to the finish that they’re targeting.”

Smith adds, “We don’t want to be just a dip shop, we want to be more of a strategic partner with our customers and learning about their pain points and how we best work together to solve those.”

Haasch points out the importance of such an ideology during a time when the whole of manufacturing is grappling with supply chain constraints. As companies experience difficulties in the procurement of materials they typically use, it can be beneficial to find new ways to get to an end solution.

“They’re trying to get to some of these end applications or end solutions maybe a little bit differently. They may be investing more or less in certain types of materials, depending on where their supply chain is situated. They may be doing the same thing as it relates to automation or other processes,” Haasch says. “I think what we’re doing well is that we’re taking our philosophy of really listening to industry segments — our customers, our business partners — and then matching that with a diverse set of capabilities.”

A focus on growth

Pioneer is focused on a strategy of growth that is prevalent in all aspects of its company culture. In 2021, the company launched an incentive compensation program that takes every employee into account. In 2022, Pioneer is investing in a leadership and talent management initiative that Smith says includes not only software but an investment in individuals who will be leaders in each location.

Pioneer’s strategy for cultivating its workforce and its culture includes several educational initiatives. The company partners with local schools on STEM programs and works with the Northeast Wisconsin Manufacturing Alliance (NEWMA), helping to educate students about the manufacturing industries. Pioneer has also partnered with Curative Connections (Green Bay, Wisc.), a group that works to find job placement for cognitively disabled individuals. The company recently received an Employer of the Year award from Curative Connections and the State of Wisconsin.

Smith explains that ultimately, the goal of these initiatives is to “not only reinforce the culture at Pioneer, but also to reinforce the commitment to employees, to help them understand their business, and most importantly, to help them understand what is it that our customers need, and why we’re moving in the directions we are.”

Related Content

Finisher’s ‘Top Shop’ Status Attracts Business

This competitive California finisher made it a goal to become a PF Top Shop. After earning the recognition, the company experienced an immediate increase in business and a challenge to obtain certifications.

Read MoreBryan Leiker, MFACA, Discusses CARB Public Hearing Over Calif. Hex Chrome Ban

Bryan Leiker, executive director, Metal Finishing Association of California, offers a recap of a January 27, 2023, public hearing conducted by the California Air Resources Board prior to an impending ruling on a proposed ban of hexavalent chromium use for finishing operations in the state.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read More10 Anodizing Best Practices

Following this list of guidelines can help to increase the performance, cost effectiveness and quality for your anodizing operation.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More