Acid Copper Technologies for Plating on Plastics

Automotive OEM performance requirements continue to increase which presents increased challenges to the supply chain to provide acceptable parts. This presentation will introduce a new system of acid copper technologies that have been designed to increase performance, widen the process operating window, reduce rejects and ultimately increase production capacity.

A Synopsis* of a Presentation given at SUR/FIN 2017 (Atlanta, Georgia)

by

Chrissy Pullara**

MacDermid Enthone Industrial Solutions

Waterbury, Connecticut USA

Editor’s Note: The following is a synopsis of a presentation given at NASF SUR/FIN 2017, in Atlanta, Georgia on June 21, 2017 in Session 12, Automotive II: Decorative Systems to Meet OEM Demands. A pdf of this brief can be accessed and printed HERE; the complete Powerpoint presentation is available by clicking HERE.

ABSTRACT

As more complex parts are being utilized in the automotive industry the need for more robust plating processes becomes critically important. Automotive OEM performance requirements continue to increase which presents increased challenges to the supply chain to provide acceptable parts. This presentation will introduce a new system of acid copper technologies that have been designed to increase performance, widen the process operating window, reduce rejects and ultimately increase production capacity.

Introduction

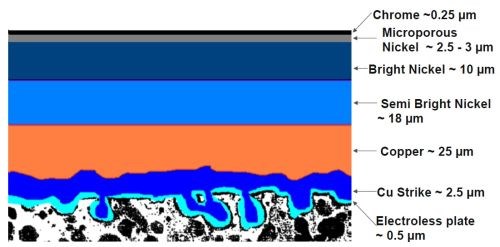

A major ingredient in the commercial success of plated decorative copper-nickel-chromium on platable plastic (generally ABS) moldings, is the use of acid copper as the first plated layer in the multi-layer system (Fig. 1). It produces a bright level surface which contributes to the overall appearance of the plated finish. In addition, it buffers the effect of stress created between the plastic and the nickel layers due to quick changes in temperature. All of these characteristics depend on the general requirements for acid copper plating, including (1) good brightness across the entire current density range, (2) its leveling power, (3) good ductility of the copper layer and (4) a minimum defect rate.

Figure 1 - Elements of the multilayer Cu-Ni-Cr system for plated plastics.

The demands of the market have encouraged the need for a more robust process technology. A more diverse range of parts, more complicated part geometries, and improved molding quality have led to stronger OEM performance specifications. These include increased copper thickness, improved thermocycling performance and still lower deposit stress. To meet these requirements, the supplier must increase thickness without reducing capacity, increase operating current densities and use more complex shielding to eliminate burning. Leveling performance must be enhanced to eliminate surface defects, such as orange peel, over-leveling, flame patterns and pitting.

Complex geometries may require the use of auxiliary anodes. The plating on plastics (POP) applicators are currently struggling with the geometry problem. Burning must be avoided in the high current density areas while throwing power must be maintained in the low current density areas. In addition, pitting on parts and covering underlying molding irregularities are major challenges.

Meeting the challenge with dye-free acid copper

The process solution discussed here involves the use of a dye-free acid copper process, which provides the following advantages:

- Good leveling

- No over-leveling

- No sludge formation

- Clean tank walls & anode bags

- Reduced risk of pitting

- No need for carbon filtration

- Excellent throwing power

- Lower risk for flame patterns

Over-leveling

Over-leveling is a phenomenon occurring at sharp edges of the workpiece. The result is a double-edged appearance and is particularly noticeable on bright and satin finishes (Fig. 2).

Figure 2 - (L) Double edge effect with conventional acid copper; (R) normal edge with dye-free acid copper.

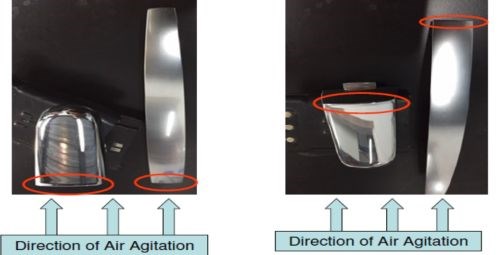

Figure 3 - (L) Over-leveling occurs when sharp edges face the air agitation stream; (R) over leveling avoided when edges face away from the air agitation stream.

In certain cases, over-leveling can be controlled by changing the rack design. In Fig. 3, the part position directly exposes the sharp edges to the air agitation stream (left photo). By inverting the position of the parts, those edges face away from the air stream, which eliminates the double edge appearance (right photo).

Surface quality

On the surface, leveling is significantly improved with a dye-free acid copper process, as shown in Fig. 4.

Pitting is notably controlled, as shown in Fig. 5.

Figure 4 - Leveling performance (L) with a conventional acid copper versus (R) a dye-free process.

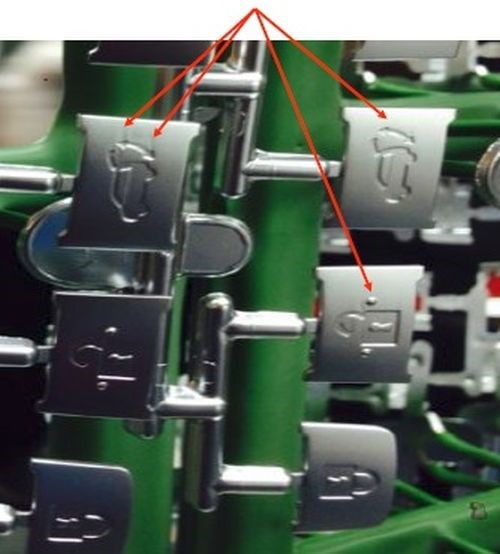

Flame patterns, or striations, caused by local turbulence around designed protrusions or concavities in the workpiece (Fig. 6), present an example of the increased complexity of parts today. These too are better controlled with the dye-free acid copper layer.

Figure 6 - Example of flame patterns.

Beyond the over-leveling phenomenon discussed previously, one might expect that edge effects could result over excessive plating time. With the dye-free electrolyte, no edge defects were observed, even after three hours of plating time.

Process advantages

Dye-free acid copper also affords improvements in process operation. The copper can serve as an intermediate layer for a variety of nickel-chromium systems and is used in standard ABS, as well as PC-ABS.

With the more complicated designs necessitating the use of auxiliary anodes, concerns over carrier and other breakdown products produced at such anodes was of concern. In one case study, high-performance liquid chromatography (HPLC) scans were used to monitor these products, and no significant brightener consumption was observed.

The same case study indicated other improvements in operating conditions. The dye-free process was capable of running at a higher temperature (86°F) with increased additive usage, or loss of leveling or brightness. The current density could be increased from 25 to 40 A/ft2 without burning, allowing increased thickness without reducing production. The need for carbon filtration was eliminated. Analysis of the solution was easy and accurate, with a bubble tensiometer used for controlling the surfactant, and HPLC used to monitor any breakdown products. Overall, less maintenance was required for the dye-free system.

In sum, a dye-free acid copper process offers the opportunity to meet more stringent OEM requirements for Cr-Ni-Cr plating on plastics without sacrificing quality and productivity.

About the author / presenter

Ms. Chrissy Pullara has over 15 years of industry experience, including research and development, technical service and marketing. She has been involved with the development of new technologies and works closely with automotive, motorcycle, plumbing and consumer goods OEMs to ensure that these technologies meet the highest standards of aesthetics and performance. She joined MacDermid after getting her chemistry degree from Bucknell University. During the following five years, she accepted increasing responsibility in applications while achieving her masters in chemistry from Southern Connecticut State University. Ms. Pullara expanded her expertise to the industrial business, where she quickly learned the decorative technology for which MacDermid is famous. She grew to take on management of the entire decorative product line, and also assumed responsibility for business development for the decorative portfolio of technology. She is now recognized as an industry expert in decorative finishes throughout the automotive supply chain.

*Compiled by Dr. James H. Lindsay, NASF Technical Editor

** Corresponding author:

Ms. Chrissy Pullara

Decorative Business Development & Product Manager North America

MacDermid Enthone Industrial Solutions

245 Freight Street

Waterbury, CT 06702

Phone: (203) 278-6783

E-mail: Chrissy.Pullara@macdermidenthone.com

Related Content

Material Database Enables Coating Thickness Measurement Without Calibration

The database from Coatmaster AG has calibrations of over 400 different RAL colors.

Read MoreCalculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

Read MoreAESF Heritage: SUR/FIN 2000 – European Academy of Surface Technology: Copper Microelectrodeposition: The Influence of Different Additives on Growth in Microprofiles

In this work, a pH 3.0, 0.8M copper sulfate electrolyte was used for plating onto both blanket and patterned silicon wafers. This novel electrolyte, proposed by U. Landau, involves a number of beneficial effects with respect to the conventional bath.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More