Advanced Solvent Technology for Medical Device Cleaning

An insider's look at new critical cleaning technologies being used in the manufacture of medical instruments.

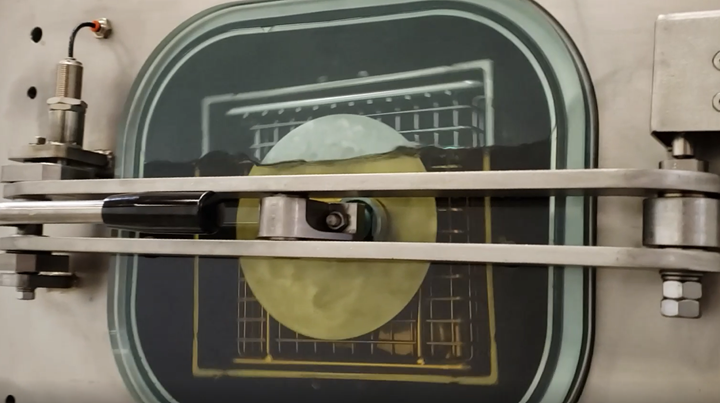

Immersion process inside a vacuum degreaser.

Photo Credit: All photos courtesy of Kyzen Corp.

In the medical world, “cleanliness is crucial”! All medical devices — whether they are disposable, implantable, or reusable — must be cleaned during the manufacturing process to remove manufacturing soils. Reusable products must also be thoroughly cleaned and sterilized between each use to avoid infecting patients or causing illness.

Medical device OEMs must provide proof their products are “clean” as part of the FDA approval process. The manufacturing process must ensure contamination-free surfaces as infection prevention and control is critical to the health of patients.

Increased demands for quality and reliability call for continuous improvements in the cleaning of the components used in everyday medical activities. The final product must meet all specifications in a manner that assures compliance. Manufacturing cleaning methods must get the job done as well as meet environmental, health and safety concerns.

Biocompatibility cleaning

What makes a material biocompatible? In a broad sense, biocompatibility is defined as having properties that make a material or a device compatible with the human body. Example: a catheter that does not trigger blood clotting or another reaction because of its contact with the bloodstream is considered to be biocompatible.

Most production parts are cleaned before being released, several times in some cases. In an industry where production time, volume and quality are critical, it is increasingly important to ensure medical parts obtain desired results once they are packaged by the end-user. That is why parts cleaning is more important than ever. Facility managers are seeking to become more familiar with aqueous and solvent cleaning solutions to learn the advantages and disadvantages of each approach.

There are many choices when it comes to selecting cleaning processes and chemistries in order to provide the performance level required. In addition, both soils and materials of construction are constantly changing, so it is more important than ever to stay up to date on innovative technologies to meet new and growing demands.

Parts exit clean and dry after process.

Solvent cleaning

General solvent degreasing is an existing process many medical device OEMs use today. Today’s cleanliness specifications for precision and critical cleaning indicate that most metal parts cannot have any contaminant or rinse water residue on the product, thus increasing the interest in solvent cleaning agents. Solvent advantages include:

- Performance with multiple soils

- Multi-materials compatibility

- Rapid cleaning cycle

- Penetration into confined spaces

- Residue-free drying

- Recoverable/reusable

Unlike aqueous cleaners that must be matched to the specific process substrates, solvents can generally offer:

- Multi-metals compatibility

- Multiple elastomers compatibility

- Multiple and tenacious lubes removal compatibility

- Ease of application

- Assured drying

- Very low surface tension

- Lower energy consumption, therefore lower cost of operation

- Less floor space requirement

- Recycle/re-use (cost-effective/decreased waste disposal)

- Water-free process

Solvents in medical device cleaning applications

Some implanted devices or instruments use metals such as titanium, stainless steel or other alloys that are selected for corrosion resistance, compatibility with the body to reduce rejection, and yield long-term reliability/endurance.

These metals are selected for the manufacturing processes to form/shape the end device. For example, the metal thickness for pacemaker cases is very thin for weight reduction and size. These thin-walled materials typically require a lubricant to assist in the stamping or forming process that will alleviate any abrasion or galling as well as enhance the metal elasticity properties.

Typical manufacturing lubes used in the forming process tend to be difficult to remove using an aqueous process. This is where a solvent process is generally perceived as superior due to the ability of a solvent to remove the soils quickly and thoroughly. The solvent being used can be recycled with the soils separated from the solvent stream. The recycled solvent can then be re-used in the cleaning process — thus providing substantial cost-savings thru solvent conservation and reduced waste disposal.

In some applications, the use of a solvent cleaning process is preferred versus aqueous due to the nature of the soils to be removed and other contributing factors such as:

- Production throughput (desired cleanliness level/process time/operational cost)

- Production methods/material handling

- Cleaning equipment requirements

- Available floor space

- Energy consumption

- Waste stream treatment/disposal cost

New solvents vs. old solvents

Most solvents, old and new, will clean. However, a lot of solvents are being phased out or becoming more restricted by the U.S. government due to environmental, health and safety concerns. As a result, many are moving toward more environmentally green cleaning processes for complex and challenging parts and moving away from legacy halogenated solvents such as perchloroethylene (PERC), trichloroethylene (TCE), methylene chloride (MC), and 1-bromopropane (nPB). If you are using these solvents, it is recommended that you obtain and review the EPA’s “Final Chemical Risk Evaluation” for your solvent. While any future forecast is uncertain, the move to phase out these solvents is certain and underway now.

Here are some questions you should consider.

- Is your current solvent at risk of being phased out?

- Do you plan on retaining a solvent cleaning process for various reasons?

- Are you struggling to achieve consistent results with aqueous cleaning due to complex components or soils?

If you answered yes to these questions, modified alcohol might prove the sustainable solution you seek.

A new technology

Modified alcohol is a water-free solvent with excellent cleaning power. It is a single chemistry that cleans parts made with oils or water-based coolants. It is also distillable and highly recoverable. Modified alcohol is formulated to provide precision cleaning in closed vacuum degreasers and offers the following advantages:

- Effective cleaning — both polar and non-polar soils (process flexibility)

- Non-HAP solvent (Hazardous Air Pollutant)

- Water-free process

- Operator and ambient production area isolation (safety plus)

- Low solvent consumption (cost savings)

- Residue-free drying (no carry-out of fluids)

- Ultra-low VOC emissions (environmental compliance)

- Solvent can be recycled/re-used for extended periods (cost savings)

- Removed contaminants condensed (reduced waste disposal/cost savings)

It also meets environmental compliance as a non-hazardous, biodegradable organic solvent. It is RoHS compliant, chlorofluorocarbon (CFC) free, halogen free, non-flammable and is REACH approved.

The future of solvent degreasing

For the user who elects to retain a solvent cleaning process due to choice or necessity, the future use of solvent is viable using modern enclosed automated vacuum degreasers.

These systems offer an excellent cleaning choice for a wide range of soils with the ability to clean and dry parts without separating them. They feature continuous removal of soils from the bath which enhances parts cleanliness level. The operator, as well as the ambient plant area, are isolated from the cleaning process which is performed in a sealed vacuum chamber (safety plus).

There are numerous features to allow multiple process cycles such as:

- 360° work basket rotation or adjustable angle oscillation

- Ultrasonics

- Hot vapors and immersion cycles

- Multiple liquid process stages

- Flushing sprays

- Vacuum drying

- Various degrees of filtration

You can future-proof your process selection by incorporating these systems into your production process. There are a wide variety of brands, models, features, etc. on the open global market. Most use a modified alcohol solvent instead of the older generation traditional solvents.

Conclusion

There is an abundance of information available in today’s world to consider the best cleaning method to suit your needs from government resources, environmental organizations, equipment manufacturers and chemical suppliers, to technical papers and consultants. Many companies will perform cleaning analysis of your parts using a specific process to verify the results before you make a commitment. It is recommended that you use these resources to conduct a thorough study as you investigate your options.

Related Content

Masking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreFinishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreTop Shop Builds Original Systems for Coating Medical Devices

Engineers at Surgical Coatings in Colorado have been ingeniously developing their own equipment, automation, processes and software since this powder coater’s inception in 1995.

Read MorePrecision Coating Receives ISO 14001 Certification

The company says its commitment to the environment and its health led it to seek this certification.

Read MoreRead Next

Automation Smoothes the Way for Surgical Coatings

Medical device coating company discusses how automation enables increased abrasion resistance and improved insulative properties for electrosurgery.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More