Anodized Frames Go Off-Road

Alternative finish gives Trek mountain bikes an edge in durability and appearance.

Readers of this magazine understand better than most that a unique finish can set a product apart in a crowded marketplace of look-alikes. The right finish can enhance consumer perceptions of quality and durability, while providing a pleasing appearance that differentiates the product from its competition.

Case in point: bicycles with anodized aluminum frames from Trek Bicycle Corp. (Waterloo, WI). Known as the bicycle supplier to the professional cycling teams of seven-time Tour de France winner Lance Armstrong, the company manufactures a full line of bikes for road and mountain.

In 2003, Trek responded to requests from riders and dealers to provide a more durable metallic finish on some of its high-end off-road bikes by teaming with Pioneer Metal Finishing (Green Bay, WI) to develop anodized frame finishes for some 2004 bike models.

Testing, Testing

Pioneer developed anodizing specifications and processes based on input from Trek design engineers. “The concept was, they wanted to develop an anodized frame finish,” recalls Pioneer engineer Chris Haasch. “Within that framework we discussed colors, and from there Pioneer went through a pretty thorough sampling process. We looked at different finish options and worked with Trek to see what they liked. Based on feedback from one sample, we’d develop the next.”

According to Haasch, samples encompassed everything from different surface finishes, including blasting and other processes, to development of custom colors. “We have the ability to vary our base colors to create some different shades,” he says. “So we focused our capabilities on what Trek thought would be of most interest in the marketplace.”

The Process

Frames for the high-end mountain bikes are fabricated at Trek’s Waterloo, WI, plant from three aluminum alloys, then shipped to Pioneer’s Minneapolis, MN, plant for finishing.

Haasch says the use of multiple alloys complicated the finishing process, especially pretreatment. “When you have different alloys, typically that affects cleaning and pretreatment the most. So we had to develop a kind of all-purpose cleaning and pretreatment process.”

Pretreatment includes blasting before the frames enter a multi-step cleaning process using both acid and alkaline tanks. In addition to providing a more consistent finish, blasting has the added benefit of improving the fatigue life of the frames.

According to Haasch, proper rinsing is a key to the cleaning process. “One of the challenges of working with the frame tubes, which include welds, is getting a good rinse in areas that want to retain solution,” he says. “So, we have to perform multiple rinsing steps between each active cleaning step and after anodizing.” Line operators have the ability to tilt and move the work in-line to get better drainage, he adds.

The multi-step pretreatment minimized variability of the anodized finish on the various frame alloys. “If you looked very closely, you could probably pick out some very minor finish differences between the different sections of the frame,” Haasch says. “But in most cases, it’s very difficult to

tell.”

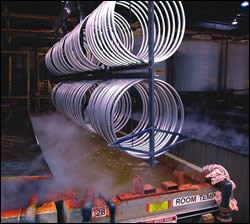

After pretreatment, frames head to the anodizing line. Pioneer’s 50,000-sq-ft Minneapolis plant includes an anodizing cell and workers dedicated to production of frames and other components for Trek. The company uses a similar setup to anodize rims for Trek in its Green Bay plant.

Haasch says the anodizing process itself is pretty standard. Parts on custom titanium racks flow down one leg of the horseshoe-shaped line and back up the other. Frames take about two hours to complete the cleaning and anodizing process. The line runs five days a week, two shifts a day.

Process control includes computer-controlled heaters and chillers on all active tanks. Rectifiers monitor voltage, amperage and time during the anodizing process. Physical part movement is controlled by a line operator, who uses a crane to lift the bar and move parts from tank to tank. Operators also use a PC to call up the required program for each part number, then set the rectifiers for the required amperage and time.

Pioneer started producing frames for two bicycle models in only two anodized colors, blue and black. Currently, anodized frames for multiple bike models are available in five colors: black, blue-gray, pewter, gold and red. According to Haasch, colors are selected very carefully to assure consumers can easily distinguish between anodized and painted frames.

“Trek also offers a painted version of all the frames we anodize,” he explains. “With the anodized frames, they’re trying to offer their customers a higher-end finish within the product line. That’s what dictated the focus on certain anodized colors.

“For example, Trek won’t select an anodized color that’s the same as a painted color, because it would be difficult for customers to differentiate between a painted and an anodized version of the bike. Each frame style we do has a unique color.” According to Haasch, of the bike models that Trek offers with an anodized finish, about 10% are purchased with an anodized frame and 90% with a painted finish.

Post-Processing

Pioneer also adds value for its customer by laser marking and applying stickers, badges and hardware to frames. “When Trek gets these frames in, they go right down the assembly line in Whitewater, WI,” Haasch says.

He explains that laser engraving Trek’s logos on the frames provides a more durable alternative to painted or pad-printed marks. And, he adds, different effects can be achieved by varying laser power and other processing conditions.

Anodizing Benefits

According to Trek product graphic designer Chad Bailey, anodizing accomplished the company’s goals of boosting product differentiation and durability. “The anodized look is distinctly different from the frames we paint, and our riders know that anodizing is much more durable as well,” he says.

Reduced weight is another benefit for cyclists, many of whom are obsessed with paring a few grams here and there from their machines. At less than 0.001-inches thick, the anodic coating weighs far less than a painted finish.

“Bicycle rims are a great example,” Haasch says. “If you weigh a rim before and after anodizing, the rim is actually lighter after processing. So there’s certainly a performance benefit, and it’s safe to say that all bicycle rims that Trek produces in the United States are anodized.”

The other big benefit, especially for mountain bikes, is finish durability, according to Haasch. “Paint is very susceptible to scratching, whereas anodizing, because of its hardness, is very difficult to scratch or scuff,” he says.

Bailey says Trek’s experiment with anodized frames has been a success. “The anodized frames have been an important addition to our product line. Our riders who have purchased bicycles with anodized frames are now expressing an interest in anodized swing arms, forks and rims.”

Other Trek product lines could also be candidates for anodized finishes. The company produces bicycles under the Klein, Gary Fisher, Lemond and other brand names, as well as Bontrager wheels and other components.

Related Content

10 Anodizing Best Practices

Following this list of guidelines can help to increase the performance, cost effectiveness and quality for your anodizing operation.

Read MoreUnderstanding PEO Coatings

Using high-speed cameras and back side illumination (BSI) sensor technology to analyze plasma electrolytic oxidation.

Read MoreChicago-Based Anodizer Doubles Capacity, Enhancing Technology

Chicago Anodizing Company recently completed a major renovation, increasing its capacity for hardcoat anodizing and Type II anodizing.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)