Calibration of Expectations (and Rectifiers)

Breaking down the three major parts of calibration for rectifier use in the metal finishing industry.

When asked if I can calibrate a set of rectifiers for a customer, of course I say yes. Any technician worth their salt can perform the necessary adjustments on a machine to bring it under tolerance. But what I find most interesting is the various requirements customers want or need in their facility. It seems that everyone has a different definition of calibration and what their quality program requires. So, when I said earlier, I can calibrate, I meant it. What I do next is ask about their process, procedures, customer requirements, and standards before I determine my scope of work and what it would cost to accomplish it.

One of my favorite customers (whose genius shall remain nameless) asked me to calibrate his facility. I produced my certificate for each rectifier, calibrating each rectifier as close as I could get it to what my calibrated measurement devices reported. Mostly Rapid Power and Dynapower rectifiers and a Clinton Power unit. I aimed for a minimum of 2% or lower deviation from ‘actual.’ I finished up in the lab and inspected the hull cell rectifiers. These rectifiers were off by over 14% in voltage. I couldn’t believe it — big red flag. That level of variation would send an entire automotive or aerospace facility into product tracing. But, this hull cell ran current control and was accurate to 1%. Since this was the main method of control in the use of the hull cell, the tests were fully compliant to the company’s quality manual. They had an acceptable 20% tolerance on voltage for the rectifier, but 1% for the current. My point here is that the customer dictates the process controls and tolerances based on the required level of control and precision for their process,

Let’s break down the three major parts of calibration for rectifier use in the metal finishing industry and where you should spend your efforts to manage your process.

- The control and regulation of the rectifier

- The reference gauges for output and feedback

- The delivery of power to your process

The rectifier regulation is arguably the most important factor in whether you can use your rectifier properly. The modern-day rectifiers (not ones with the big three tap switch dials mounted to the front) have a switching system built into them that is regulated by circuit boards. The switching system could be using IGBT (insulated-gate bipolar transistor), SCR (silicon controlled rectifier), diodes, motorized windings, or any combination to give you the regulated control you are looking for. This method of voltage and current delivery relies on the user inputting a command or target and the rectifier does its best (while following the laws of electricity and control capabilities of the rectifier) to deliver this power to the tank. The regulation circuit of the boards in the rectifier are also tied to the safeties and emergency inhibit of power in many instances. This makes calibration of the regulation circuit both a necessity for quality control, but also imperative for operator and process safety. Here, the tighter the tolerance the better. You cannot compromise in accuracy and precision when dealing with safety for your workforce.

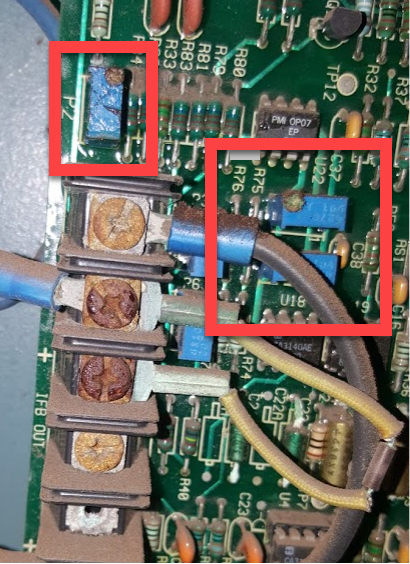

Calibrating the regulation circuit of a rectifier typically includes both an offset, or bias, which is the “zero point” in the scale from 0 – 100% of the range. The span, or gain, is the “Maximum Point” of the scale from 0 – 100%. It is best practice to adjust the offset first, then the gain. You should verify 0%, 25%, 50%, 75% and 100% settings to verify the object you just adjusted is consistent along the entirety of its operating range. You then need to repeat this process for each control parameter the machine uses. It is probable that you will need to repeat adjustments to the offset and gain multiple times in 4-20mA circuits. They are a bit trickier to master calibration of, as the adjustment of the 4mA “Zero Point” changes the slope of the linear scaling of the amplifier. (The y intercept of the line in a 0-5 volt or 0-20mA circuit is the zero point. In 4-20mA circuits, the y intercept is not the zero point, and has a much larger effect on the slope of the line with adjustment).

The potentiometers responsible for calibration on a sample regulation board. Chemical contamination plays a major role in calibration drift nationwide. All images courtesy of Dynapower.

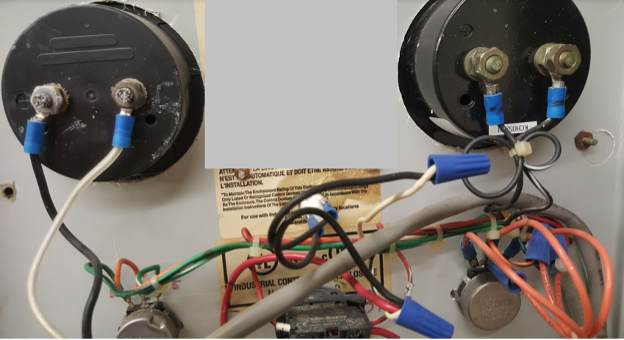

Reference gauges on the outside of the rectifier, like process gauges in the panel of the operator stand and the gauges on the dashboard of your car, are independent meters that respond to stimuli. The analog or digital meter in the remote-control station for your operators is a “dumb” meter — it has no way of “fact-checking” the signal it is being fed. Herein lies the rub: If you hire a metrology company to calibrate your meters, they will verify the signals coming into the meter are scaling the meter or gauge appropriately. In other words, if you feed the meter a bogus signal that has nothing to do with anything the rectifier is currently doing, the meter only knows to react to that provided stimulus.

The process implications are dire. If the rectifier is damaged and in need of repair, but the rectifier signal card is putting out an inaccurate signal to your meter, your meter could be both working and accurate in displaying the value associated with the inaccurate signal being provided. This could lead operators to make the wrong decisions in the process and create costly rework or worse. Your operators are only as good as the information you give them — similar to how the display meters are only as good as the signals you give them. This is the number one problem I see in the field when working with product defects related to the rectifiers. Display values of the measurement devices for current and voltage are off, and the operators are responding to the bad information being provided to them.

Image of wire nuts and foreign wires bringing in an incorrect feed signal to the meters.

The final segment of calibration is delivery of power to your process. If you run identical chemical processes but path your electricity to the tank with copper on one and steel on the other, you are bound to get different performances from each tank. If your process depends on the precise delivery of electricity to your tank, knowing what distribution of electricity to the process is imperative. The big trend for barrel platers over the last 10 years has been smaller rectifiers on multiple cells, rather than one big rectifier across the entire cell operation. The multiple, small rectifiers allow current controlled barrels to be set to the square footage loaded into them. This preferred method of loading and process parameters has helped cut defects and maximize efficiency per barrel of parts. It even seems to compensate for unevenly loaded barrels.

In larger lines with longer runs of bussing from the rectifier, companies can run in voltage control — this means that you set the rectifier to provide a constant voltage to the tank and rely on even distribution in the bussing to feed the parts with electricity. If your process is running in voltage control, then the bane of its existence will be voltage drop through the bussing. If your connections have high resistance due to chemical contamination, rough surfaces, dust and dirt, or poor contact surface area, this can wreak havoc on your even distribution of power. I have even seen zinc-plated parts de-plate to bare substrate before leaving the tank because the current couldn’t reach the parts near the end!

Process meters can be tied to deliverable voltage or current to the parts or different sections of bussing distributing power. These process meters can be used to make decisions about increasing or decreasing power to meet your quality requirements. Some rectifier boards can use a downstream distribution shunt for regulations purposes. It is important to check for voltage drop in the bussing and clean the connections when they start generating excessive heat or too high of a drop. If you are using meters for end distribution of power, you calibrate them like any other reference gauge for your rectifier, making sure the input stimulus is being accurately translated and displayed. Calibration starts with the zero point and ends at the full range.

Loose bussing connections from rectifier to tank will start creating hot spots and degrading the power distribution to your process.

Related Content

Liquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreNanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreRead Next

Interview with Remington Schieffer, field services supervisor, Dynapower

Products Finishing sits down with 40 Under 40 Class of 2021 inductee Remington Schieffer to hear how he approaches his work and his thoughts on the finishing industry.

Read More40 Under 40: Class of 2021

Each year, PF editors comb through a long list of nominees with a wide range of skill sets to select the 40 Under 40 class. This year's finalists include engineers, operations managers, chemists, general managers, sales professionals and entrepreneurs working in the finishing industry.

Read MoreA New Family of Rectifiers

Dynapower has announced the launch of its new RapidX family of rectifiers, including both pre-engineered SCR and air-cooled SMPS rectifiers.

Read More