Can You Afford to Not Use Custom Masking?

Are you weighing the costs of a custom masking solution vs. an off-the-shelf solution? Christy Schulthess of Custom Fabricating & Supplies discusses the overall savings that can be realized with custom masking.

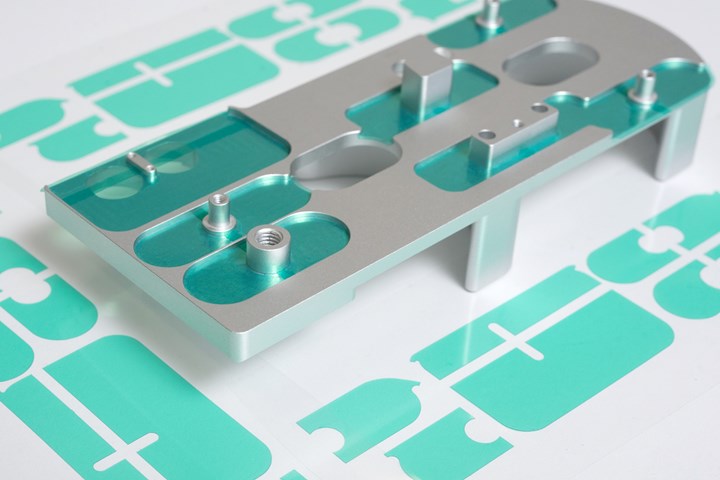

Despite requiring an up-front investment, custom masking solutions can improve efficiency and profitability.

Photo Credit: All images courtesy of Custom Fabricating & Supplies

Q: I’m investigating the cost differences in customized masking versus off-the-shelf standard solutions. I’m trying to get a holistic idea of costs over time. Can you offer some perspective?

A: “It’s so expensive.” Far and away, this is the response heard as to why companies choose to make do with standard, off-the-shelf masking products. But is this actually saving your company money in the long run?

In speaking with an industry insider, it was relayed that the most time-consuming task on a paint line was masking. Yet, we rarely hear much about masking options outside of the old standby tapes, caps and plugs that are found online at dozens of suppliers’ websites. Custom options do require a larger up-front investment; however, those costs are often recouped within days or weeks with the labor savings.

Let’s take a look at this part that was brought in for a custom tape masking solution. We sat down with a standard roll of green polyester tape and a custom die cut. It took 30 minutes with just a roll of tape, whereas it took five minutes to mask with the custom green polyester kit.

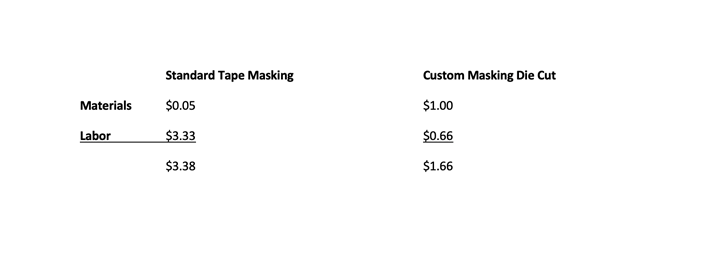

It should be acknowledged that we are not going to be nearly as efficient in masking as someone that performs the application many times a day. If we adjust those numbers to what a paint line supervisor may see from their crew, it may be closer to 10 minutes with a roll of tape and two minutes with a custom kit. Let’s assume an unburdened labor rate of $20/hr.

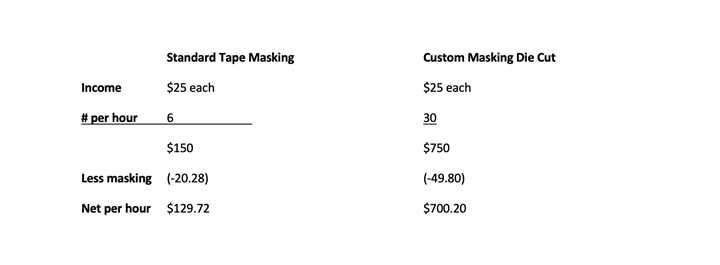

We can see that there are straightaway savings on just labor per part. However, there is the additional consideration of how many parts can be run in an hour or day. Let’s assume that this part is being billed at $25 for coating. What is the possible income from each type of masking (assuming all other costs are equal)?

As we see, time is the real cost in masking, not the masking itself — even when the custom masking solution is 20x the cost of an off-the-shelf solution.

There are additional savings that can be achieved with custom masking as well, derived from reductions in internal rework, scrap and CoPQ charges. For one customer, standard masking was costing them $10,000 a week in scrapped and reworked parts. That is a huge outlay that could easily pay for custom plugs.

One poorly masked part delivered to a customer can result in rejections and hundreds of dollars in cost of poor quality charges at $300 a pop — regardless if it was 1 or 10,000 parts; a $2 part or $1,000 one. When taking all these indirect costs into consideration, a $2,500 tooling charge for a custom molded part becomes justifiable very quickly.

Time studies will often yield surprising results. Be sure to investigate all of the hidden costs before sticking with catalog items. Reach out to custom masking providers. They often will have many options that can help make you more efficient and profitable!

About the Author

Christy Schulthess

Christy Schulthess is the marketing director for Custom Fabricating & Supplies. Visit customfabricate.com.

Related Content

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

More to Masking

How finding the right masking solution impacts your finishing operation.

Read MoreLeveraging Technology for Rapid Custom Masking Solutions

When should you consider a custom masking solution? Christy Schulthess of Custom Fabricating & Supplies discusses how today’s technology is putting specialized masking options within reach.

Read MoreApplications Innovation Leads to Better Masking Solutions

When masking product failures are costing you money, it pays to work with an expert that can select or engineer the most efficient solution.

Read More

.jpg;maxWidth=300;quality=90)