With the continuing advance of conventional subtractive manufacturing technologies like multi-axis machining and increasing utilization of metal 3D printing (additive manufacturing) for part production, manufacturing managers and engineers are faced with new and complex challenges related to part deburring and surface finishing.

In times past, much of manufacturing was concentrated on producing large volumes of parts as economically as possible. Many of the mass finishing technologies still in use today were developed to handle large workflows of identical parts and produce edge and surface finish conditions that were consistent and uniform. Part-to-part and lot-to-lot consistency was a major consideration in the development of these technologies, as well as an important driver of the economic advantage that the processes offered.

While uniformity and consistency are still very important part attributes, just-in-time, flexible-manufacturing and avoiding production bottlenecks, as well as other quality-based manufacturing philosophies are driving significant change on the factory and shop floors. These changes are having a significant impact on deburring and mechanical finishing operations. In many cases, there is a much stronger need to be able to quickly process smaller lots of more complex parts with much tighter tolerance and surface finish requirements.

New Challenges with 3D-Printed Parts

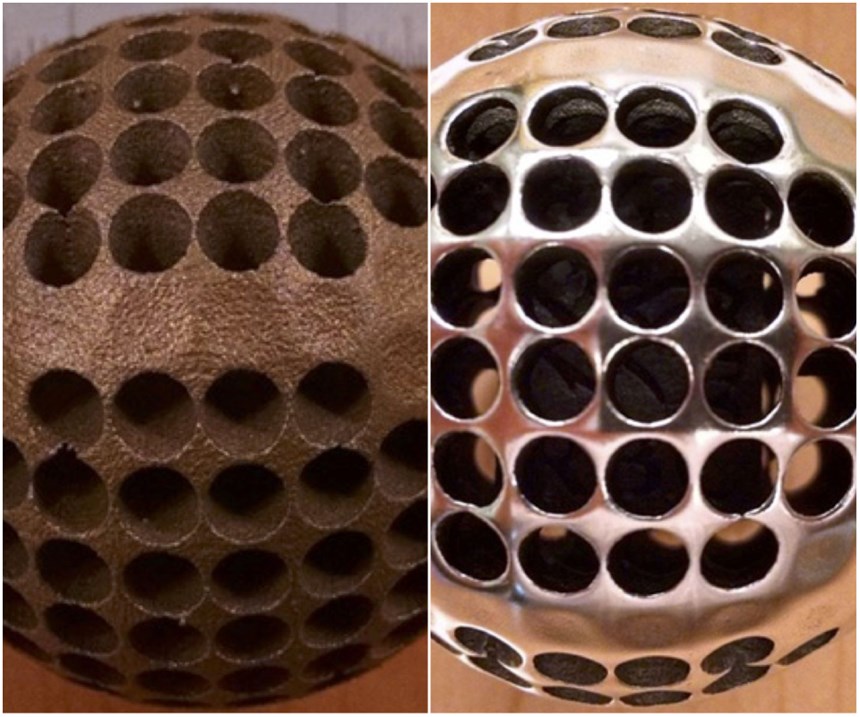

Metal parts manufactured using various additive manufacturing technologies present a new and entirely different set of challenges for surface finishers. Unlike with conventional manufacturing technologies, additive manufacturing does not produce parts with substantial burrs, which are by-products of cutting or metal-forming operations. Printed parts also are free of the non-isotropic machining or grinding patterns common to subtractive operations that can have negative effects on part wear and fatigue resistance.

In many cases, however, 3D printing does produce unacceptably rough surfaces on parts, and this poses severe challenges for many mechanical surface finishing methods. Sometimes the surfaces of printed parts rival those of unfinished casted parts in terms of their initial surface roughness and positive skew. High-energy finishing methods are required to produce acceptable surface finishes with process cycle times that won’t be a source of bottlenecks or production constraints.

A High-Speed, High-Energy Alternative

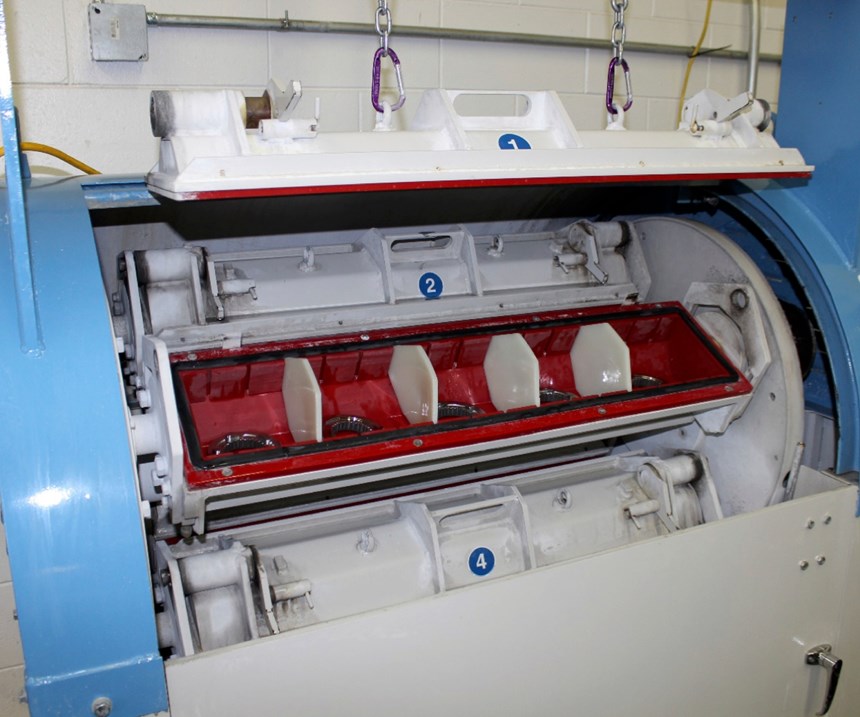

Centrifugal iso-finishing is a high-speed and high-intensity mass finishing method in which abrasive or polishing materials are caused to interact with part edges and surfaces with 10 times the surface pressure of low-energy finishing methods. What this means, in practical terms, is that it is possible to produce very refined surface finishes in abbreviated process cycle times. It also means that parts with complex and detailed geometries can be deburred with a minimum of manual intervention. This is because the higher surface pressures generated in the equipment makes it possible to utilize much smaller dimensioned media effectively. And the smaller dimensions of these preformed media make it possible to access areas that cannot be reached with more conventional media commonly used in lower energy positive-displacement or kinetic surface finishing methods.

The increased complexity and precision requirements of machined parts have reinforced the need for more accurately producing and controlling their surface finishes. Variations in surface texture can influence a variety of performance characteristics. It can affect the part’s ability to resist wear and fatigue, assist or destroy effective lubrication, increase or decrease friction and/or abrasion against cooperating parts, and resist corrosion. Because these characteristics are critical under certain operating conditions, the surface finish can dictate the performance, integrity and service life of the manufactured parts.

Following are some of the features and benefits of centrifugal iso-finishing:

Sequential Processing. To meet more demanding surface finish requirements, many of today’s more sophisticated mass finishing operations rely on multiple-step sequential processing, which enables very rough surfaces to be brought to a highly polished or micro-finished state. It involves initially processing the parts with coarse abrasive material, followed by a sequence of steps using finer abrasives. Each of these subsequent steps uses an abrasive material that has been calculated to clear and blend the abrasive pattern left on the surface by the preceding step. To use a common analogy, in woodworking applications, it is necessary to sand with successively finer abrasive grits to produce furniture-quality surfaces. The same principle holds true for mass finishing metal and some plastic parts to get very smooth micro-finished surfaces.

Flexible Processing. Many two- or even three-step centrifugal barrel finishing processescan bring part surfaces to very low, micro-inch surface profiles. Centrifugal iso-finishing processes often can process these several steps within the same equipment, as the equipment typically is furnished with four processing compartments.

Katie MacKay, vice president of Mackay Manufacturing in Spokane, Washington, says her company transitioned to centrifugal iso-finishing when it was struggling to process a very complex aluminum part that had numerous drilled holes, edges and planes, and required eight hours of hand-deburring. After centrifugal processing, the hand-deburring was reduced to less than an hour, justifying the purchase of the equipment. Since then, centrifugal processing has become the standard finishing method for her company. Without the machine, Mackay would need an additional three employees on its deburring staff.

Since the installation, Mackay says the company has developed processing for more than 50 additional part numbers made from titanium, steel, stainless steel, aluminum and plastic. More than two dozen different finishing “recipes” are used to process the different parts to specification, in some cases, to highly polished surfaces with low micro-inch surface values. Almost all the deburring and finishing needs of this 135-employee 50,000-square-foot shop is serviced by one machine.

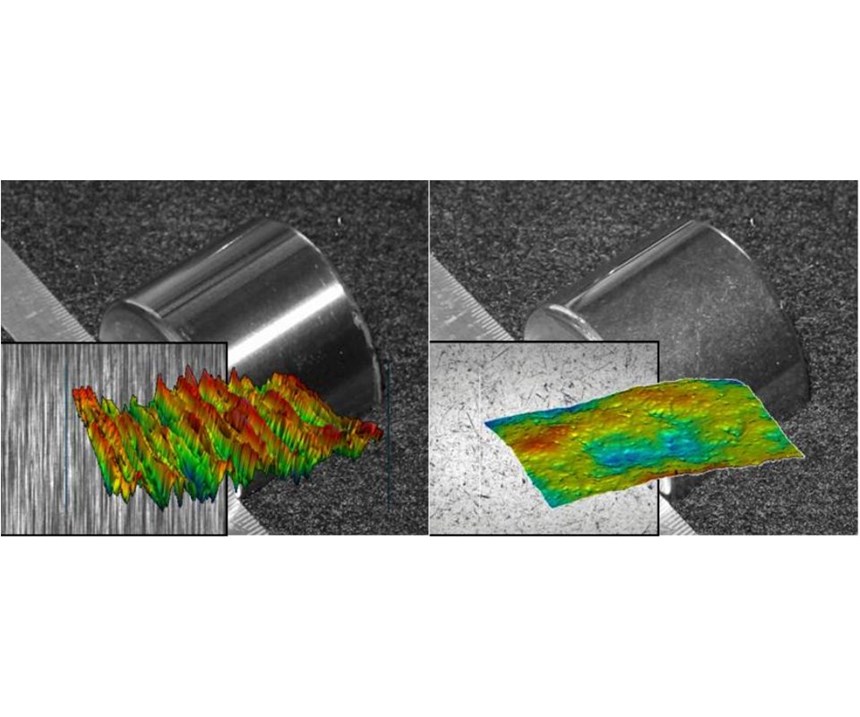

Surface Skewness. Manufactured surfaces are typically characterized as being either negatively or positively skewed. This surface characteristic, designated as Rsk, is the measure of surface symmetry about the mean line of a profilometer graph. Unfinished parts usually display a heavy concentration of surface peaks above this mean line, indicating a positive skew. These positively skewed surfaces can be undesirable, negatively impacting the performance of parts in applications where there is substantial surface-to-surface contact. Centrifugal iso-finishing can truncate these surface profile peaks and achieve negatively skewed surfaces that are plateaued, presenting a much higher surface bearing area. Jack Clark, an early pioneer in the use of centrifugal iso-finishing on race car engines, was able to extend the useful service life of Formula One-like engines that normally had to be pulled after one or two races to an entire racing season.

Surface Texture Patterns. Also important is the directional nature of surface textures developed by typical machining and grinding methods. These machined surfaces are characterized by tool marks or patterns that are aligned and directional in nature. Tool or part life and performance can be substantially enhanced if these types of surface textures can be altered into one that is more random in nature. Post-machining processes that use free or loose abrasive materials in a high-energy context can alter the machined texture substantially, reducing peaks and developing a random scratch pattern on the surface. These isotropic surfaces improve part wear and fatigue-fracture resistance.

Residual Stress. Machining and grinding processes tend to develop residual tensile stresses in part surfaces. These stresses make parts susceptible to premature failure. Centrifugal iso-finishing processes can modify surface stress conditions and replace them with uniform, compressive stresses. Many manufacturers have discovered that, as these processes have been adopted and the parts involved have developed a working track record, the parts are better—not just in the sense that they are burr-free or have smoother surfaces, in that they last longer, are less prone to fatigue failure and exhibit better tribological properties.

Processes such as peening are commonly used to improve metal surface integrity, mitigate crack propagation and improve service life. It has been found that high-energy sequential finishing with loose media can develop not only compressive stresses, but also very level or negatively skewed plateaued surfaces simultaneously. The improvements in wear resistance can be significant.

In one application, stamping dies used for forming the tops of aluminum cans were given a useful life of approximately 10 times that was anticipated of parts that had not been finished with this method. Another application cited by J. Bernard Hignett in an SME technical paper involved extensive cycling tests conducted by a spring manufacturer: “This ability to improve resistance to fatigue failure is graphically demonstrated by the results of some tests made by a manufacturer of stainless steel coil springs. A group of springs was taken from a standard production run. Half of the sample was finished in the manufacturer’s usual manner of barreling followed by shot peening, while the other half was CBF-treated for 20 minutes. The springs were then tested to failure by compressing them to a stress change from 0 to approximately 50,000 psi. The results showed that all the springs finished by the conventional method failed between 160,000 and 360,000 cycles. The springs that had been processed by CBF failed at between 360,000 and 520,000 cycles, an average improvement of 60 percent.”

The Importance of Surface Finish

The mechanism that allows for improved “functionality” for all surfaces is basic to surface performance: to accept the loads imposed and resist wear. Traditional processes that generate form and control fit do not necessarily dictate how that part or assembly will function over time. In recent years, manufacturers have realized that there is another contributor to long-term part performance: surface finish. If a manufacturer does not account for surface finish characteristics like lube retention, microburr removal, identification of torn and folded material, directionality, and load-bearing capability, the performance of components in the system cannot be predicted. High-energy finishing processes can also contribute to more predictable and extended service life by developing useful and uniform compressive stress equilibrium in parts as a hedge against premature fatigue failure.

Through progressive process development and a more mature understanding of the “function” of surfaces, manufacturers can design parts for systems that perform over predictable, extended lives. This is the key to reduced warranty costs, reduced scrap, higher quality, lower production costs and satisfied customers. Although the ability of of centrifugal iso-finishing processes to drive down deburring and surface finishing costs when compared to manual procedures is well-known, their ability to dramatically effect part performance and extend service life is not nearly as well understood by the manufacturing community.

Dave Davidson is with SME and works as an advisor to its Machining/Material-Removal Technical Community. He can be reached at dryfinish@gmail.com. He also would like to acknowledge Jack Clark of Woodward Inc., Dr. Michael Massarsky of Turbo-Finish Corp.,Thomas and Cole Mathisen of Mass Finishing Inc., Michael Klein of Iso-Finishing Inc., and Katie MacKay of MacKay Manufacturing Inc. for providing technical assistance for this article.

Related Content

Hexavalent to trivalent chromium — the environmental benefits

Regulatory pressures to switch from hexavalent chromium to trivalent alternatives are a growing concern for many finishing operations. In this Products Finishing Ask the Expert clinic, Brittany McKinney of Pavco discusses the environmental considerations driving these regulations.

Read MorePrecision Coating Receives ISO 14001 Certification

The company says its commitment to the environment and its health led it to seek this certification.

Read MoreLiquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

Read MoreAnode Answers for Hard Chrome Plating

While problems continue to rise with using lead anodes for hard chrome plating, some manufacturers are discovering platinized titanium anodes as a much-improved alternative with a long list of advantages.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)