2015 Hall of Fame Inductees

William Blum, Henry Brown, Michael Faraday, Richard Hull and Oliver Watts have been selected.

Electroplating legends William Blum, Henry Brown, Michael Faraday, Richard Hull and Oliver Watts have been selected as the 2015 recipients for membership in the Electroplating Hall of Fame.

A committee of industry experts and veterans aided Products Finishing magazine in selecting the second class of honorees to be picked for the Electroplating Hall of Fame.

More than 40 individuals were nominated by readers for selection. The committee then reviewed the nominations and voted on the top five individuals for the honor.

The 2015 class joins current members Luigi Brugnatelli (1761-1818), Colin Fink (1881-1953), Lubomyr Ramankiw (1931-), Kevie Schwartz (1902-1974) and John Wright (1808-1844), all of whom were named to the inaugural class by Products Finishing magazine in 2014.

Nominations for the 2016 class will begin this fall. The selection will then take place by a vote of the industry committee and the inductees will be announced next Spring. Visit pfonline.com for more information about the nomination process and past winners.

The 2015 selection committee members were James Abbott, Dave Anzures, Richard Crain, Brad Durkin, Jim Jones, Richard Leopold, James Lindsay, Dave Marsh, Jerry Poll, William Saas, William Rosenberg and Erik Weyls.

Dr. William Blum led the electrodeposition section of the National Bureau of Standards, and was president of the Electrochemical Society in 1926. Over the years, he authored 12 papers and co-authored a dozen more on electroplating. From 1903 to 1909, he taught chemistry at the University of Utah, where he came into close contact with the copper and lead mines and smelters. In 1909, he became a chemist at the NBS in Washington, D.C., where he was assigned to investigate the cause of certain difficulties encountered in the copper electrotyping baths at the U.S. Government Printing Office. He later joined the American Electroplaters’ Society, with which he became closely associated. Until 1951 when he retired, Dr. Blum directed the work of the NBS Electrodeposition Section, which had more than 100 employees. More 100 technical papers on plating were published by the group. In 1953, the American Chemical Society awarded him a certificate for 50 years membership and made him an “Emeritus Member.” In 1958, Dr. Blum was the first winner of the AES Scientific Achievement Award, which ultimately was named in his honor. Dr. Blum died in 1972 at the age of 90.

Born in New Jersey in 1907, Dr. Henry Brown went to work for the Udylite Corp. in Detroit in 1934 his first assignment was to improve an acid cadmium plating bath and develop a high-speed alkaline cadmium cyanide bath. His principal work became the development of organic addition agents, especially for bright nickel plating baths. He developed the sulfonamide and sulfonamide “carrier” brightener system; the elucidation of unsaturation as one of the essential characteristics of the best organic addition agents for bright nickel plating, which devolved into the system of using an unsaturated organic sulfon-compound together with auxiliary unsaturated compounds that is the basis for all modern bright nickel baths. In 1951, he suggested the development of the perfluoro alkane sulfonic acid surfactants for the purpose of suppressing acidic spray. Dr. Brown retired from Udylite in 1972, but continued to make many contributions to science for the rest of his life, including cancer research. He died in 2001 at the age of 93.

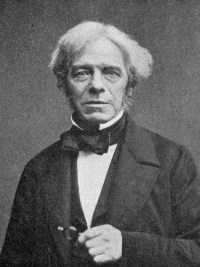

Born in 1791, Michael Faraday is perhaps the greatest experimental scientist in history, and most of his research is the basis to both the understanding and the practical use of electrolytic processes. Albert Einstein kept a picture of Faraday on his study wall, alongside pictures of Isaac Newton and James Clerk Maxwell. Faraday observed in 1832 that the amount of substance undergoing oxidation or reduction at an electrode in a cell during electrolysis is directly proportional to the amount of electricity that passes through the cell. This statement is known as Faraday’s Law of Electrolysis. The quantitative unit of electricity, now called the Faraday, is the amount of electricity that reduces one gram-equivalent weight of a substance at the cathode of an electrochemical cell and oxidizes one gram-equivalent weight of a substance at the anode. This corresponds to the gain or loss, and therefore the passage, of Avogadro’s number of electrons.

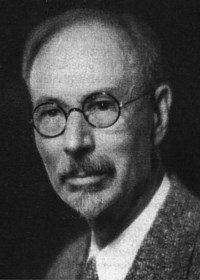

Among Dr. Richard Ostrander Hull’s patented inventions is the “Hull Cell,” which forever changed the world of plating. In 1944, Dr. Hull started the R.O. Hull Company, a firm that was eventually absorbed into Atotech. The company was best known for supplying corrosion inhibitors to the chemical and oil industries, but Hull realized that they could be used as additives for electroplating. Business instinct told him that he needed a test to assess “macro throwing power,” or current density ranges for optimum performance. The same instinct took him to a simple plating cell with a varying anode-cathode spacing and its launch in 1939 was a patent and then a conference technical paper for the American Electroplaters Society. The claims for the Hull Cell were to optimize current density range, to optimize additive concentrations, to recognize impurity effects, and to indicate macro-throwing power capabilities.

Dr. Oliver Patterson Watts, a University of Wisconsin chemist, delivered his landmark research paper ‑ “Rapid Nickel Plating” in April 1916 at the American Electrochemical Society meeting, research that resulted in the modern Watts Nickel Bath. From 1913 to 1915, Watts studied the plating industry and in 1916 published his considered opinion that an optimum solution should be based on nickel sulphate 240 g L–1, nickel chloride 20 g L–1, and boric acid 20 g L-1. By using it at 70°C, ˝high speed˝ electrodeposition (20–30 A dm–2) could be achieved, the cathode current efficiency was 90 percent, and the anode current efficiency 98-100 percent. The Watts formulation was adopted very slowly at first, but its inclusion in the standard textbooks later helped to make it more widely known. Dr. Watts died in 1953, having enjoyed a long retirement of travel and outdoor activities.

Nominations for the 2016 class will start in November.

Related Content

Nanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

Read MoreHow to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

Read MoreTroubleshooting Alkaline Zinc

One of the most common problems that can arise when plating with alkaline zinc is an imbalance of brightener in the solution. In this helpful Ask the Expert article, Chad Murphy of Columbia Chemical discusses how different zinc metal concentrations and brightener concentrations can impact efficiency.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)