Cleaning Prior to PVD/CVD Coating

Determining the cleanliness and chemical de-coating of PVD/CVD layers.

About 45 years ago, the introduction of aqueous cleaning of laboratory glassware replaced the use of chromium sulphuric acid, a very hazardous and carcinogenic cleaning method.

Since that time, aqueous cleaning processes have advanced significantly. Today, they are an effective and environmentally-friendly method to achieve a residue-free surface on nearly any substrate material. Aqueous cleaning processes have replaced a significant number of solvent-based cleaning processes in the field of cleaning prior to coating.

Determining and monitoring surface cleanliness prior to PVD/CVD-coating is important for achieving a perfect coating. Chemical de-coating of PVD/CVD layers, such as TiN, TiAlN, DLC, and CrC is in higher demand in the PVD/CVD coating industry.

PRINCIPLES OF CLEANING

Residue-free aqueous cleaning is successfully used in the following fields:

Prior to PVD/CVD-coating

Precision metal parts

Ophthalmic and precision optics

Flat glass for displays

Photovoltaic

For a highly sophisticated cleaning process, four factors are important:

Time: Usually 1 to 5 minutes per process step is ideal.

Detergent: Can be acidic, neutral or alkaline.

Mechanical effects: This can be Brownian molecular motion (soaking bath), mechanical treatment (brush or hand cleaning), spray pressure (washer), cavitation (ultrasonic bath)

Temperature: Usually cleaning is done at a range of room temperature up to approximately 90°C

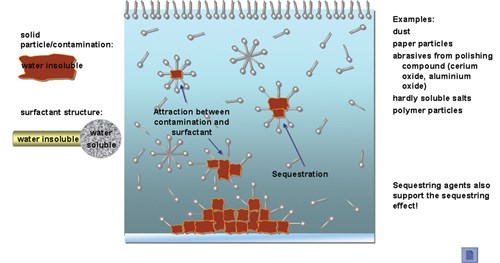

The removal of oils and solid contamination is mainly done by surfactants, which have both hydrophilic and hydrophobic regions. This chemical structure enables the surfactant to bring the contaminants into the aqueous solution. The sequestering agents prevent the formation of deposits on the clean substrate and prevent the re-deposition of detached particles of dirt and contaminants, especially abrasives. This process is shown in Figures 1 and 2.

The alkaline detergents undergo chemical reactions with the organic contaminations.

Both reactions lead to better water solubility of contaminations.

Solvent cleaning can be described as a homogeneous dissolution of the contaminations in the solvents. Solvents are not able to perform chemical reactions with the contaminants removed.

Aqueous cleaning is a totally different philosophy and has some major differences compared with solvent degreasing. With aqueous cleaning, chemical reactions become possible—and chemical reactions support the cleaning process.

STEPS OF CLEANING PRIOR TO COATING

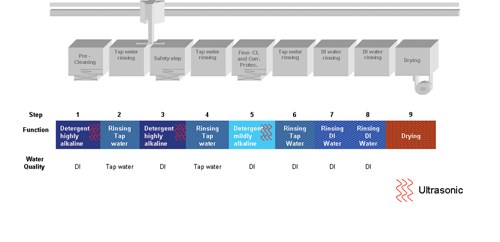

The aqueous cleaning process prior to coating is usually a nine step process:

Bath 1 is for pre-cleaning, where most of the contaminants are removed. The use of an oil separator is strongly recommended in this step.

Bath 2 prevents carry-over of detergent and contaminants from Bath 1 to Bath 3, which leads to a longer useful lifetime for Bath 3. An additional advantage is that the product compatibility of the detergents used in Baths 1 and 3 is not critical.

Bath 3 is for additional cleaning if the substrates are grossly contaminated or the detergents in Bath 1 are near exhaustion. Alternatively, Bath 3 can be used with an acidic detergent if there’s a need for a deoxidation step in the process.

Bath 4 prevents the carry-over of detergents and contaminants from Bath 3 to Bath 5.

Bath 5 is usually a mild alkaline, final cleaning step prior to rinsing and coating. The bath can also be used to prepare the parts for final rinsing with the addition of a corrosion inhibitor for substrates susceptible to oxidation.

Bath 6 improves the rinsing properties of the cleaner used in Bath 5 and prevents the water purification reprocessing system from becoming heavily contaminated with cleaner components.

Bath 7 and Bath 8 are connected in cascade and have the function of the final rinsing with demineralized water. Step No. 9 is the drying step.

To prevent corrosion, the cycle times in the rinsing steps often have to be adapted to the corrosion sensitivity of the parts.

To prevent the formation of spots in final rinsing, the following points also have to be taken into account: The DI water quality used must be less than 0.5 µS/cm. The replacement rate of the DI water in the rinsing baths should be the volume of the tank per total process time (including lift-out). The basket design for the parts is very important to minimize the carry-over of pure water into the drying step and the drying system, which if used, must be powerful enough.

The residue-free cleaning of the parts is of utmost importance for PVD/CVD coating processes. Without a residue-free surface, the resulting PVD/CVD coating can fail or be rejected. This leads to expensive rework (de-coating and recoating). A perfect cleaning process is a key factor to achieving a perfect PVD/CVD coating. The better the cleaning, the higher the yield rate of the PVD/CVD coating process.

ANALYSIS OF THE CLEANLINESS

It is important to analyze and to monitor the cleanliness of the substrates prior to coating. This can be done by the following four methods:

IR-Spectroscopy

The most useful for identifying chemicals that are either organic or inorganic. It can be used to identify and quantify some components of an unknown mixture.

Particle analysis

Makes it possible to determine the size and numbers of particles that have been collected post cleaning by fine filtration of the cleaning fluid.

Contact angle

The angle at which a liquid/vapour interface meets a solid surface. The contact angle is specific for any given system and is determined by the interactions across the three interfaces.The measurement of the contact angle of a water droplet is a quick and simple way to evaluate cleanliness of a solid surface. The correlation of cleanliness and contact angle is shown in Figure 3.

TOC-Analysis

Total organic carbon is the amount of carbon bound in an organic compound and is often used as a non-specific indicator of water quality or cleanliness of pharmaceutical manufacturing equipment. Virtually all TOC analyzers measure the CO2 formed when organic carbon is oxidized and/or when inorganic carbon is acidified. Subtracting the inorganic carbon from the total carbon yields the TOC.

De-coating processes are of great interest to the tool manufacturers and end users for the following reasons:

Carbide substrates are very expensive.

Tools can be re-coated several times if there is no damage prior to rework.

De-coating followed by applying new coatings is less costly compared with the cost of fabricating new tools.

To save new tools where there has been a failure in the coating process (e.g. by failure of coating system, wrong coating applied).

Chemical de-coating is a very helpful tool. Compared with sand blasting, chemical de-coating has the advantage of lower labor cost and leaves no damage to the substrate.

The following systems can be successfully chemically de-coated:

CONCLUSIONS

Cleaning prior to PVD/CVD coating is key to achieving high yield in the PVD/CVD coating processes. This article examines the principles of aqueous cleaning prior to PVD/CVD coating, describes the methods to determine the cleanliness and offers a review of the chemical de-coating processes for PVD/CVD-layers.

Dr. Henry Percy Ederle is the Area Sales Manager Industrial Division, Borer Chemie AG in Switzerland. For information about Borer Chemie, please visit Technotradeinc.com

Related Content

Top Shop Emphasizes Dedication, Work Ethic

With a primary focus on aerospace and defense work, American Metaseal Corp. of Arbutus, Maryland, has qualified as a Top Shop on multiple occasions.

Read MoreVacuum Degreaser Cleans Up a Messy Situation

By replacing its immersion parts washer with a vacuum degreasing system, this machine shop is much more efficient, saving the company money, man hours and the health of the operators.

Read MoreReplacing Open-Top Vapor Degreasing in Aerospace Manufacturing

Options and considerations for cleaning aerospace parts as regulations tighten on vapor degreasing solvents.

Read MoreUnderstanding Robotic Vacuum Impregnation

Robotic vacuum impregnation can be used to seal porosity, minimize scrap, increase throughput and reduce costs.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More