Cyclic Nucleation System Safely Cleans Complex Parts

LPW Reinigungssysteme GmbH has developed PowerJet, a modular cleaning system that offers the safe, effective cleaning of any part using only water and the cyclic nucleation process (CNp).

The manufacturing of precision components in industries such as medical, optics and semiconductors is associated with tight specifications for technical cleanliness. These specifications require small parts with even smaller crevices that are contaminated with oils and/or particles to be cleaned efficiently. LPW Reinigungssysteme GmbH (Riederich, Germany) has developed a chamber (single or multi) system for the critical cleaning of parts, which also has a clean room option. Called the PowerJet, this modular system offers the safe, effective cleaning of any part using only water and the cyclic nucleation process (CNp). Other benefits include a high filtration rate, the ability to integrate into an existing production process, and more.

Cyclic Nucleation Process

The PowerJet’s CNp is a cleaning technology integrated into its basic system. It is especially designed for cleaning complex parts with small crevices where undercuts and narrow channels are present.

The CNp technology is a vacuum flood cleaning method in which parts in a filled and sealed vacuum chamber are brought into contact with the cleaning fluid. The resultant gas bubbles are formed on all reactive surfaces, even in complex part structures such as capillaries and holes. If there is a sudden removal of the vacuum, these fall into each other (implode) and generate a pressure wave (cavitation effect) with a mechanical effect on the entire surface of the components, even in concealed areas. This method can be used alone or in addition to conventional cleaning methods.

Thinking Outside the Box

New manufacturing processes such as 3D printing, new product requirements resulting from trends in the automotive industry and the transfer of parts to subcontractors give cleaning professionals more challenges to consider when deciding on the best cleaning system for their applications. To meet all the requirements, an appropriate cleaning system must be capable of combining cleaning and drying processes for complex parts. Using these parameters as a basis, LPW developed the PowerJet with the following features as standard:

- Closed, clean room-compatible chamber system for two batch sizes with one cleaning tank and two separate rinsing tanks

- CNp in all process stages for cleaning concealed areas of a part

- Cylindrical media tanks

- High-volume flows for all cleaning and rinsing media

- Adjustable movement variables

- Separator for light organic residues and suspended solids

- Hot air drying, vacuum drying

Because the system is water based and uses CNp, it is safe for cleaning almost any type of material (metal, plastic and ceramic), including delicate parts as well as durable parts that include difficult to remove contaminants.

This LPW PowerJet fully automated, two-chamber system is for cleaning medical devices using ultrasonics and CNp.

Preventing Cross-Contamination

Even when the best practices are in place, it’s often a challenge to keep the customers’ parts clean after they run through a cleaning process, as mishandling during transportation or packaging can lead to more dirty parts.

To prevent recontamination or cross-contamination, LPW implemented several features within the PowerJet to ease these concerns. First, the system provides continuous filtration so there’s no contaminants that remain in the fluid that can recontaminate the part.

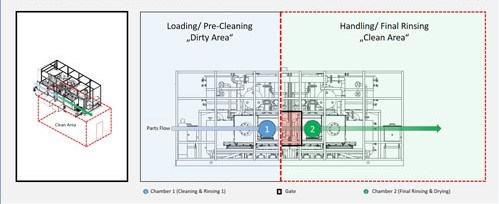

This diagram shows the PowerJet Twin system with CNp, ultrasonic technology and an adaptable clean area.

Although the PowerJet has the option of single or multiple chambers, choosing a system with more than one chamber has its advantages. For example, with two treatment chambers, the cleaning stage can be separated from the rinsing stage without any carry-over, increasing throughput significantly.

Other optional features include a treatment chamber or clean room, rinsing tank, 25- or 40-kHz ultrasonic device or multi-frequency sound, integrated distillation for rinsing water treatment, demineralized water circulation system, automatic feeding automation with stainless steel design, and CNp drying and preparation for steam rinsing and steam drying systems. The machine, with options for single or multi-chambers, comes in three sizes or can be custom built.

Case in Point

The first of the new PowerJet systems was delivered to a medical device manufacturer. It was designed as a fully automated CNp double chamber unit with four media tanks. The instruments are partly covered with coatings that cannot be cleaned by ultrasonics, as it would damage them. Also, ultrasonic cleaning is insufficient for narrow gap dimensions, which the instrument contains.

With CNp, the bacterial load could be brought significantly below 0.5 CFU (colony-forming unites). The maximum value per part was specified to be 5 CFU. In addition, the total organic carbon (TOC) value was less than 1 ppb (the maximum acceptable value was 100 ppb) and the growth inhibition values between 0 and 4% were well below the maximum value of 30%.

Outlook

Technical cleanliness requirements are increasing in almost all industries. For suppliers, this often means that manufactured parts and components must be delivered directly to the customer’s site with proof that parts are cleaned to specifications. To meet these criteria, the supplier must be well equipped for these new tasks so they can continue to survive in the market. Implementing a cleaning unit that can handle most if not all cleaning jobs within a company is smart approach to efficiency.

Related Content

Corrosion Resistance Testing for Powder Coating

Salt spray can be useful to help compare different pretreatment methods and coatings but it does not tell us much about the corrosion resistance of a part over time in the field. Powder coating expert Rodger Talbert offers insights into how to get a better idea of how to improve a part’s corrosion resistance in the real world.

Read MoreAdvantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

Read MoreFrom Drain to Gain with Smart Wastewater Recovery

Incorporating digital monitoring to maximize performance.

Read MoreSolvent Versus Aqueous: Busting the Myths

Is aqueous cleaning “greener” than solvent cleaning? Is solvent a more effective cleaner than aqueous? These and many other questions are answered here to debunk the misconceptions that many manufacturers have held onto for years.

Read MoreRead Next

Maximizing the Ultrasonic Cleaning Process

Ideal for precision cleaning, this process works best when customized to meet the needs of each particular application.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More