Decreasing EN Plating Costs with Single-Component Solution

Detailed calculations of the true cost of electroless nickel plating reveals how converting to single-component EN solution can reduce costs and save time.

Adding a single-component solution to an EN plating bath has many advantages. Photo Credit: Surface Technology Inc. (all images)

Simplifying processes can drastically improve efficiency and save money. For plating shops, implementing a single-component EN solution might be the answer to both cutting costs and saving time.

A presentation from Products Finishing’s EN22 conference by Michael Feldstein, president and director of innovation at Surface Technology Inc. (STI) (a Products Finishing Top Shop), detailed an unprecedented calculation of the true cost of EN plating. It also revealed ways to reduce the cost, especially by converting to a single-component EN solution from the traditional three-component systems that have been used for decades.

The presentation was supported by a detailed analysis of one shop’s conversion to STI’s One-Plate 1001Q medium phosphorus, single-component EN solution as well as the testimony of 25 other worldwide plating shops surveyed about their experiences with a single-component EN solution. Traditionally, shops have focused on the narrow measurement of the cost per mil square foot when deciding which EN solutions to use in their shop. This is the cost of the EN solutions alone required to plate 0.001-inch thick EN on 1 square foot of surface area. The true cost of EN plating goes well beyond the cost of chemicals per mil-ft2.

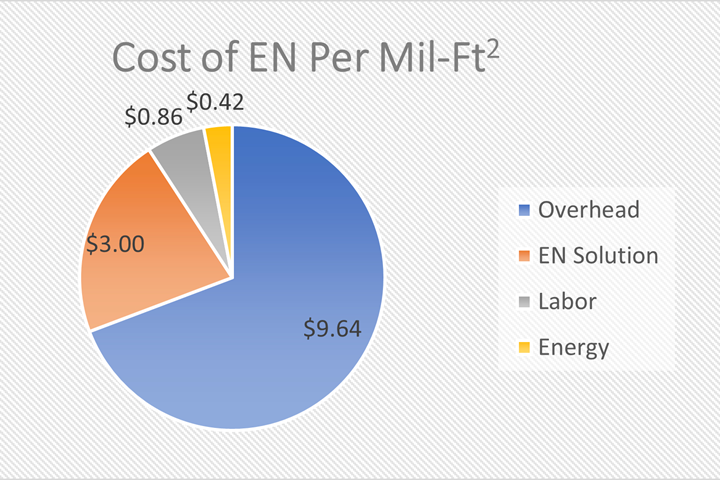

Figure 1 depicts the overall factors that make up the total real cost of EN plating 1 mil-ft2 calculated from the findings of one shop’s conversion to the One-Plate 1001Q medium phosphorus single-component EN solution. These costs can vary from shop to shop and even within a shop. But the model is an important baseline from which cost savings can be established. A figure of $3.00 per mil-ft2 was used as a reasonable average of EN costs at the time of the EN2022 Conference due to the prevailing nickel and hypophosphite prices. All other costs for the shop to apply 1 mil-ft2 of EN was $10.92 for a total of $13.92 as the actual cost per mil-ft2.

Fig. 1. These factors make up the total real cost of EN plating per 1 mil-ft2 calculated from the findings of one shop’s conversion to STI’s One-Plate 1001Q medium phosphorus, single-component EN solution.

The bath make-up cost using a single-component solution is typically 20% to 30% less than the cost to make up a bath with a three-component system. This is because a single-component only requires 15% by volume to make up a bath, whereas three-component systems typically need between 20% and 30% by volume of one or more solutions to make up a bath. Twenty-three of the 25 shops surveyed reported a lower bath make-up cost with a single solution.

There is another chemical cost savings that shops have reported that have converted to a single component from other systems. Because the single component also maintains the pH of the bath by itself, little to no ammonia is needed. This savings on ammonia can equate to a chemical savings of $0.13 per mil-ft2. Avoiding the need to pH adjust also saves valuable time and energy.

The cost of the chemistry needed to replenish the bath per mil-ft2 plated is generally about the same for any EN solution. The reason for this is straightforward: the amount of nickel sulfate and sodium hypophosphite required to deposit one mil-ft2 of EN is governed by the basic equation for EN:

H2PO2- + H2O à H2PO3- + 2H+ + 2e-

Ni+2 + 2e- à Nio

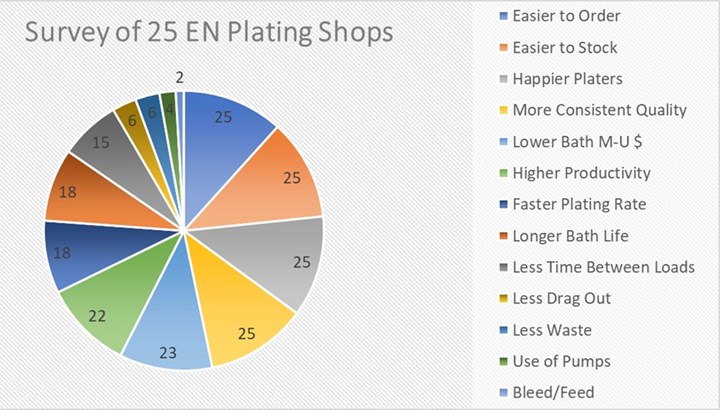

Therefore, the way to reduce the cost of EN plating is by reducing the cost of labor, energy and all other overhead. A survey of 25 shops worldwide demonstrates how such cost savings are possible by using a single-component EN solution. The results of this survey are presented in Figure 2 with how many of the 25 shops experienced each of the 13 benefits after converting to a single-component EN solution. The first four benefits (happier platers, more consistent quality, easier to order, and easier to stock) were reported by all the 25 shops surveyed.

Fig. 2. The results of the 25 EN plating shops surveyed regarding the benefits of using the single-component EN solution shows that all 25 shops reported happier platers, more consistent quality, ease of ordering and ease of stocking.

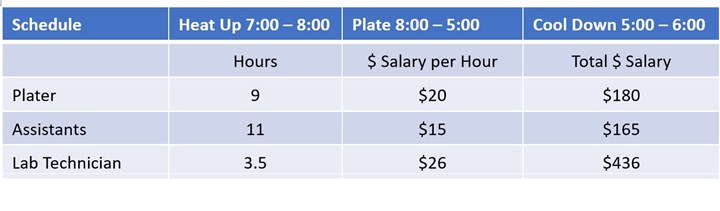

The benefits reported by these 25 shops have also been experienced in the case study plating shop in its conversion to a single-component EN solution. Their detailed cost information is as follows:

- The labor costs were $406 per day of plating time for the plater, assistants and lab support.

- Energy costs were $209 per day of actual plating time or $0.32 per minute.

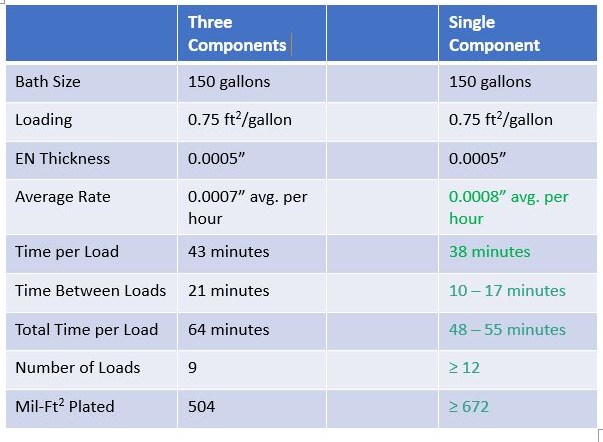

- In the studied day of plating, 504 mil-ft2 were plated when using three A, B, C components. Up to 672 mil-ft2 are possible due to higher productivity when using a single-component solution.

This chart breaks down the case study shop’s employee expenses.

Faster Plating Rate

The case study shop pays $406 for all labor directly involved in the nine hours of actual plating (not including the labor during heat up, cool down, masking, racking, quality control, and so on), which equates to $0.75 labor cost per minute. The shop has saved an average of five minutes per load due to the faster plating rate of the single-component EN bath. Multiplied by nine loads, this is a savings of 45 minutes over the course of the day. At $0.75 per minute, that means the shop saves $33.75 per day which corresponds to a savings of $0.07 per mil-ft2 when 504 mil-ft2 are plated.

In addition, these 45 minutes saved means a cost savings of $14.40 per day or $0.03 per mil-ft2 through reduced energy costs.

This chart compares the three-component EN solution to the single-component EN solution. The number of loads and the mil-ft2 plated is especially significant. .

Less Time Between Loads

Plating shops have also experienced significant savings in the time between loads made possible by using a single-component EN solution for three key efficiencies:

- Ease of adding a single component instead of two.

- The single component self-maintains the pH of the bath.

- The opportunity to use replenishment pumps instead of manually adding the single component to the bath.

At the case study shop, it has saved between 6 and 11 minutes from these efficiencies compared to the 21 minutes baseline time between loads with the old three-component system. The times between loads are now 15 minutes with a single component that is self-pH maintaining and 10 minutes with a single component added by a metering pump.

Such a reduction of 6 to 11 minutes between loads equates to a savings of $0.8 to $0.23 per mil-ft2 in labor costs. Another $0.06 in energy costs are saved by reducing the time between loads by up to 11 minutes eight times per day between each of the nine loads plated.

Less time between loads, therefore, saves money, and it also saves the bath from being hot and idle, which is never a good thing for an EN bath for stability reasons.

Efficient Equipment

These examples enable the demonstration of costs or savings per mil-ft2 for any cost factor in a plating shop, even the pumps used on a plating line. The more efficient the plating bath, the less time pumps need to be operated. The less they are operated, the longer they will last.

In this case study, the shop saved the equivalent of $0.01 per mil-ft2 due to the more efficient plating operation after converting to a single component, representing up to $1,270 per year in savings on pumps and pump repair. Moreover, the longer the pumps (and all equipment) last, the less a shop needs to pay for labor to order, repair and replace the pumps; not to mention less downtime.

Higher Quality

All the 25 shops surveyed on their experiences from switching to a single-component EN solution cited higher and more consistent quality. They reported that it is easier to maintain the bath with only one solution. The chemistry in the bath always stays in balance because all ingredients are in the single solution. The single solution is more able to replenish the bath because the nickel is more diluted than a typical A solution. Also, the single solution is pre-complexed before it goes into the bath, and the pH is the same as the bath and does not shock the bath like a typical C solution that has a pH of 9 – 11.

Even if a shop can save only 1% of its overall costs by improving EN quality, that can equate to around $0.10 per mil-ft2 of savings on all the parts that a shop plates using the analytic method. On top of that are all the other benefits of less rework.

Savings on Shipping

Plating shops pay for the shipping of the EN solutions they purchase. The shipping cost may be included in the price per gallon or a separate line item on the invoice. The cost of shipping the single component is significantly less than the three-component EN because it does not have a high pH like a typical C component nor the high concentration of nickel sulfate as in a typical A solution. The lower shipping cost of a single component can save a shop about $0.04 per mil-ft2.

More Surprising Benefits

The faster plating rate and less time between loads does not only save money for labor, energy and equipment. The higher productivity of a single component had reduced the turnaround time of these shops’ orders to their customers. Previously, the shop plated nine loads with 504 mil-ft2 in 9.6 hours. Now, they are able to coat 12 loads with 672 mil-ft2 in the same amount of time.

This substantial increase in productivity means the shop can produce more at a lower overall average cost.

All shops surveyed reported a single component is easier to order and stock.

For example, using a single component enables a shop to order and stock only one product instead of three. That simplifies the ordering process and reduces the amount of inventory and floor space needed. Platers also appreciate that with the simplified logistics of a single component:

- There is no chance of adding the wrong material to the bath

- The chemistry in the bath always stays in proper balance leading to more consistent quality and maximum bath life

- The single component in stock can be used for either bath make up or replenishment, so they are not likely to run out of material

- There is no spare material as with containers of A-B-C components that are consumed at different rates

All these factors lead to — happier platers. Efforts to make platers happier are not a common focus in the industry but should be because the results are priceless. They include increased productivity, higher quality and employee retention, which is advantageous for any shop.

Summary of Hard Cost Savings

Calculations of these factors mentioned in the article demonstrate a savings of 20% to 30% of the bath make-up cost and up to $0.64 per mil-ft2 achieved by switching to a single-component EN system, and even more depending on the degree of quality improvement achieved by each individual shop.

Read Next

Electroless Nickel Conference 2023 to Bring EN Professionals Together

ENC 2023, a three-day conference featuring electroless nickel education and networking opportunities, is scheduled for September 26-28, 2023 in Milwaukee, Wisc.

Read MoreEpisode 23: An Interview With Brad Durkin, technical director for the Electroless Nickel Conference 2022

Electroless Nickel Conference 2022 will take place October 11-13 at the Omni Severin in Indianapolis, Indiana. Learn more about the event in this interview with ENC22 technical director Brad Durkin.

Read More