Determining Ultrafiltration Permeate Requirements

Axalta’s Joe Subda explains ultrafiltration and defines permeate to help you figure out how to operate your ecoat system most efficiently.

Q: How much ultrafiltration permeate is required to operate an electrocoat system efficiently?

A: Ultrafiltration is the process of separating the low-molecular-weight components of the paint from the electrocoat bath. These low-molecular-weight components, referred to as permeate, generally consists of low-molecular-weight resin, water, solvent, acid, soluble metals and dissolved salts that accumulate as result of pretreatment.

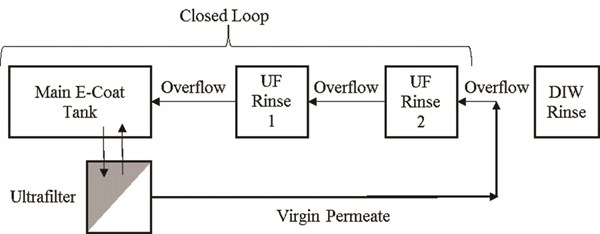

The ultrafiltration system in an ecoat system has two main purposes: provide rinse liquid (permeate) that allows for a “closed-loop” rinsing system and provide a means to purge the paint of water-soluble contaminants. Parts traveling through an ecoat tank carry out liquid or non-coated material. This carry-out consists of a thin film of electrocoat material, cream coat that adheres to the part’s surface and material trapped in recessed areas. Virgin permeate is used to rinse the part at the end of the rinse system. The permeate overflows from the last rinse, in the closed loop, into the previous rinse and so on until it reaches the main tank. This arrangement is referred to as counterflow.

The counterflow returns paint that is carried out on the parts back to the tank, creating a closed loop (see figure below). Since the rinse medium is an actual component of the paint, no compromise in paint chemistry occurs. Permeate also provides a cost-effective method for removing contaminates from the paint bath for conductivity control. Contaminates are removed by sending permeate to the drain and replacing with deionized water.

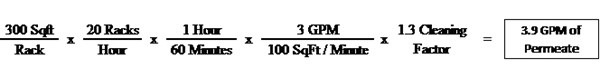

The paint recovery in an electrocoat system is dependent on the quality and volume of permeate produced. Higher paint recovery equals greater efficiency. Quality of permeate refers to the amount of paint solids in permeate. Consult your paint suppler for a recommended amount of paints solids in permeate; generally, it is less than 0.5 percent. The volume of permeate required is dependent on the square foot of parts processed, part geometry and rinse volume. The design criteria for the volume of permeate is 2 to 5 gpm of permeate per 100 square feet of metal processed in 1 minute. A permeate rate of 2 gpm per 100 square feet of metal per minute would be used for a system that processes flat parts and has a small rinse tank volumes. A permeate rate of 5 gpm per 100 square feet of metal per minute would be used for systems that process complex geometry parts and has large rinse tank volumes.

The design criteria is the minimum volume of permeate required. Ultrafilter systems are cleaned when the permeate rate reaches 70 percent of the initial volume. The ultrafilter system is sized 30 percent larger than design criteria to ensure the permeate rate does not drop below the minimum. Consult with your paint supplier on the permeate rate that would be best for your system.

For example, say a system processes 300 square of parts per rack. The square footage used should be the largest amount of parts that the system can process. The parts have some recessed areas. There are 20 racks per hour. The system has two ultrafilter spray rinses and one ultrafilter dip rinse. The permeate rate recommended by the paint supplier is 3 gpm per 100 square feet per minute. The required permeate would be 3.9 gpm.

Q: How do know when it is time to replace ultrafilter membranes?

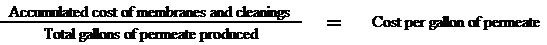

A: Flux rate of an ultrafilter membrane declines over time. When a minimum flux rate is reached, the membrane is cleaned and the flux rate recovers. The time between cleanings generally decreases as the number of cleanings increases. The time for the first cleaning might be six months, but the time between the first and second could be five months, and the time between second and third cleanings might be three months, and so on. When should the membranes be replaced? When cleanings are every two months or every month? Determining the best time to replace a membrane can be accomplished by tracking the cost of permeate per gallon, using the following formula:

As long as the cost per gallon is falling from cleaning to cleaning, it is more economical to continue using the same membranes. When the cost per gallon increases for the first time following a cleaning, it would be more economical to replace the membranes.

Joe Subda is a senior product specialist for Axalta Coating Systems. Visit axaltacs.com.

Related Content

Professional Plating Expands Zinc, Ecoat Offerings

Ever expanding, Professional Plating of Brillion, Wisc., has announced two capital investments: a second zinc line and an upgrade of its ecoat capabilities.

Read MoreECOAT24 Issues Call for Speakers

Don't miss your chance to apply to speak at ECOAT24. Submit your abstract by June 26, 2023.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreTop Shop Leader Focuses on Its People as Key to Success

Twin Cities job shop, Avtec, was named a Top Shop for the third time in 2022, due in no small part to its commitment not only to the work it produces but to those who produce it — its employees.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)