If you ask Dr. Mohammad Al-Omari, there is more in becoming a Certified Electroplater Finisher (CEF) than just having the title that goes with the rigorous coursework.

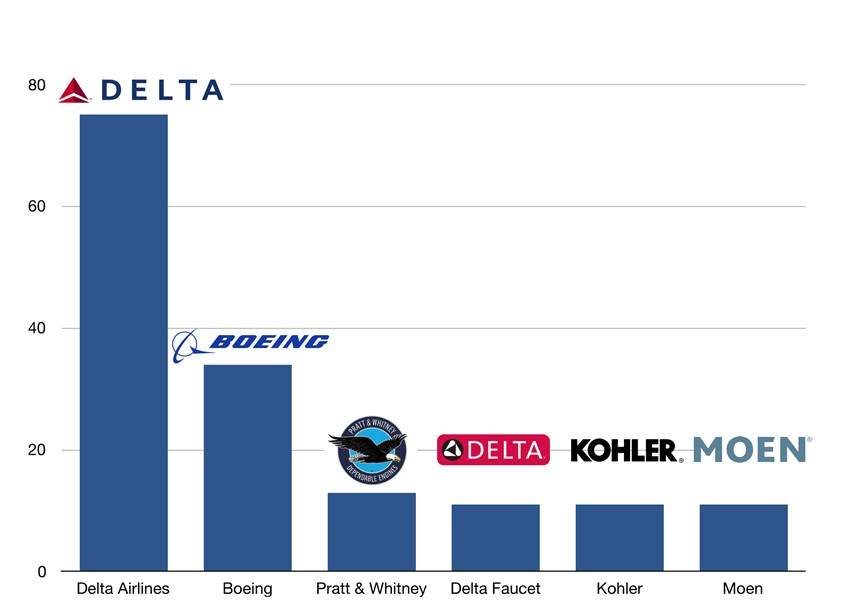

“I think it’s crucial that individuals involved with this industry attend the training as it offers multiple benefits, not only from an educational side but also networking and meeting experts which can be extremely helpful in the future,” says Dr. Al-Omari, the manager of process development for faucet finishes at Kohler Company in Wisconsin.

Stephen Gaydos, a technical fellow at Boeing Research and Technology in St. Louis, says the CEF training program offered by the National Association for Surface Finishers (NASF) offers the core knowledge needed for those in the industry to succeed.

“I think that getting CEF training provides one with the basic knowledge and tools to understand surface finishing fundamentals,” Gaydos says. “Boeing thinks any training that our employees get to improve their work skills is beneficial.”

Skills Gap Widening

As the manufacturing skills gap in the U.S. continues to widen, many believe that offering specified training in various production applications—including surface finishing—will help attract workers to those industries and strengthen the workforce development opportunities available to those employees.

A recent report by Deloitte found that almost 2.4 million jobs will go unfilled over the next decade in the U.S., which it says jeopardizes almost $2.5 million in potential economic output in that time.

“About five out of every 10 open positions for skilled workers in the U.S. manufacturing industry remain unoccupied today due to the skills shortage,” the Deloitte report states. That holds true in the finishing industry, where a lack of skilled production workers has hampered some electroplating and anodizing operations from expanding to meet their customer demands.

NASF Designations

Certified Aerospace Finisher (CAF) demonstrates specialized knowledge in materials, plating processes and quality control methods that are vital to airline manufacturing.

Certified Electroplater Finisher (CEF) demonstrates a broad knowledge of surface finishing that can be applied toward positions or business with manufacturers in a variety of industries.

Master Surface Finisher (MSF) demonstrates mastery of essential finishing processes, as well as knowledge in specialized processes and environmental stewardship. To obtain the MSF designation, students must pass exams for the following:

Primary: (Choose 1)

- Airline / Aerospace Finishing (CAF)

- Electroplating / Surface Finishing (CEF)

Core: (Choose 3)

- Aluminum Finishing

- Chromium Plating for Engineering Purposes

- Electroforming

- Electroless Deposition

- Precious Metals Plating

- Zinc / Zinc-Alloy Plating

Secondary: (Choose 2)

- Corrosion / Salt Spray

- Environmental Stewardship: Pollution Prevention

- Environmental Stewardship: Wastewater Treatment

Source: nasf.org

The NASF offers the certification courses through the AESF Foundation, a non-profit organization and an entity functioning as the educational arm of the NASF. More than 1,700 people have passed the course over the last few decades.

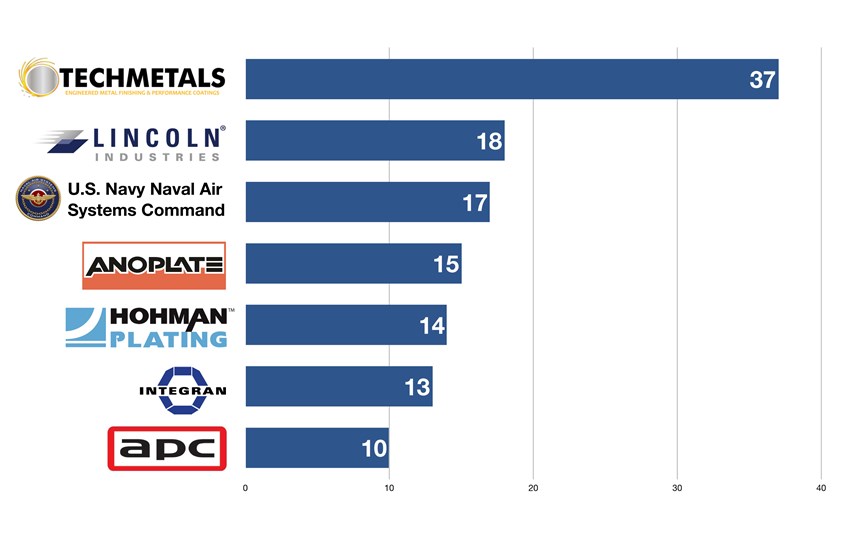

Lincoln Industries in Nebraska has 18 people who have passed the CEF test. The company recently launched Lincoln Industries University, which it says plays a huge role in the growth and development of each employee by developing leadership and technical skills, as well as inspire its people to make personal development a priority.

Carl Witte, Lincoln’s manager of process and operations systems, says that the CEF program encourages self-development, although that typically means he loses people in his entry level positions.

“Sometimes it’s for other departments, and sometimes it’s for other companies,” he says. “I think self-motivated people are just more likely to succeed with a difficult certification like CEF. I make it completely optional and make sure to set aside time so they can be trained while other team members keep their day-to-day processes up and running smoothly.”

“Shame on anyone who doesn’t take advantage of what the industry offers them.”

— Jim Romine, MSF, senior manufacturing engineer at faucet maker, Moen

Bruce Brady, who is a CEF and the process manager for commercial operations at Lincoln Industries, says workers who are apt to pursue this certification are the type who have already decided to stay with the organization long-term.

“I have suggested it to team members as one option to pursue as part of their personal development plan, but I also encourage other secondary education options as well,” Brady says. “Then I leave it up to the person to decide what best suits them. Throughout my career, I have had many opportunities to apply what I learned, and some of that advanced plating knowledge has helped me build solid relationships with customers, solve difficult problems and advance within the company.”

Incentives to Certified Employees

Some finishing shops encourage CEF training by paying for the program, as well as boosting an employees’ salary if they pass. Michigan’s KC Jones Plating offers a $5,000 increase in base pay for any team member who successfully passes the CEF exam, a by-product of workforce retention. “None of our team members with a CEF certification have left KC Jones voluntarily,” says Mark Burger, KC Jones’ business and marketing manager.

At Hohman Plating in Ohio, all process engineers are required to become a CEF, and all technical related fields such as supervisors, process technicians and quality engineers are encouraged, says Brad Kremer, the company president.

“Class time and testing are all during regular working hours, which helps allow them to complete the testing ‘on the clock,’” Kremer says. “It absolutely helps with workforce development. Helping to educate and advance the knowledge of our technical team is an important requirement for Hohman to stay relevant in the industry, and we also offer a payrate differential for any plater who achieves certification.”

Rich Macary, president of Arlington Plating in Chicago, says his shop encourages employees to take the CEF course when they review options for their personal development each year. He feels the cost is worth it to his operations.

“Usually, employees who you invest in will stay with the company longer,” Macary says. “In general, the U.S. lags behind other countries with technical training, and the CEF training system is vital to the sustainable growth of the metal finishing industry.”

Matt Lindstedt, president of Advanced Plating Technologies in Milwaukee, says the company prefers all of its engineers, lab managers and any senior line leads to become a CEF, but they also have persons within their office and customer service group that are CEFs, too.

“Metal finishing is our trade, and the CEF course is the best course available to get a good overview of what our industry and our company does,” he says. “I think it helps retention, and we find that employees—at least the right ones—thrive on a company that cares enough to invest in them and help further their profession. If an employee resists taking the exam, that tells me a lot about their long-term viability and interest in growing within our company and the industry.”

Jim Romine is a senior manufacturing engineer at Moen, as well as an MSF, one of only 75 who have attained that certification.

“Getting certified really helped me in my career,” says Romine, who recently retired after 36 years in the industry. “Shame on anyone who doesn’t take advantage of what the industry offers them. Fortunately, Moen has been extremely supportive of its workforce who want to get this additional training.”

The OEMs with the most CEFs, according to the NASF.

Cost Savings, Added Robustness

For people like Brandy Myers, a laboratory supervisor at American Trim in Ohio, getting her CEF designation came after looking at several other options for continuing education.

“Honestly, I didn’t feel as though I needed the certification, but I was interested in continuing my education in the plating industry and wasn’t sure where to start,” she says. “I also wanted to find a training course I could recommend to others in my facility, to help them better understand our processes.”

Myers says the CEF program has enabled her to perform her job better for her employer, and to work with suppliers more effectively.

“I have become more involved with our bath chemistries, and we are now able to collaborate with suppliers instead of being reliant on them to dictate how our process should work,” she says. “It has really given us a voice in how we run our plating lines, and we can manipulate bath chemistries and plating lines to fit our specific needs. Since taking ownership of our process, we have seen cost savings, a reduction in environmental impact and a robustness of our systems.”

For information on the National Association for Surface Finishing certification courses, visit nasf.org

About the Courses

The NASF and the AESF Foundation offers technical education to advance the science and technology of surface finishing. Students can choose from four study platforms:

Web-Based

- Foundation courses in a series of web-based sessions

- Live, online interaction with NASF / AESF Foundation instructors and other industry experts

- Sessions take place on pre-determined Tuesdays and Wednesdays between 12 p.m. and 2 p.m. EST

- Session recordings are available to students for 30 days after the original posting date

Home Study

- Begin a Home Study anytime and at your own pace

- Hard copy materials include lessons and homework

- Technical Education Director responds to questions about material, grades, homework and offers suggestions to improve work

- Proctored exams at your location are also available

Class Room

- Live interaction with instructor in a classroom setting

- Instruction takes place over 2-4 days (addition of one day for optional exam)

- Taught in select locations throughout the U.S.

Custom Courses

- Design your own courses to meet your company needs

- Mix and match 110 available course modules

- No travel required; we come to you

- Host a course at a time of your choosing

Prerequisites: Students should have at minimum a high school diploma. Some experience in processing parts for surface finishing is helpful but not required. The training materials and instruction are in English. Metric and/or U.S. units of measurement are used. Students are taught how to convert between the two systems of measurement.

Course Materials: Students are provided with a binder containing printed course materials. The course materials consist of a full-color print-out of every slide in each presentation followed by text that is intended to cover and, in some cases, go beyond the live presentation. Students can use these course materials for independent study and future reference. Following each lesson, a review quiz is presented to allow each student to identify their level of understanding of the more important concepts in the lesson. These quizzes also prepare the student for the associated examination.

Visit nasf.org/Education for information, email info@nasf.org, or call 202-527-0252.

Related Content

Successful South African Plater Beating the Odds

Remaining focused on quality and reliability, Team Plating Works stays profitable in a volatile and challenging economy.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreAn Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)